In fact, printed PCB circuit boards used in electronic equipment are different, and printed PCB circuit boards are classified differently according to different specifications.

First, according to the spread of printed circuit classification

According to the printed circuit around the circuit board can be divided into a single side aluminum substrate, double panel, multilayer high level pull 3 kinds

1. Single-sided aluminum substrate

Single-side aluminum substrate is in the thickness of 0.2-5mm insulating layer base steel plate, only a surface coated with copper foil, according to the way of printing and etching in the base steel plate printed circuit. Single-side aluminum substrate is simple to manufacture, convenient assembly line, suitable for a charge and discharge path, such as tape recorder, TV, etc.; Discomfort is used to specify places with high assembled relative density or complex power circuits.

2. Dual board

The double panel is printed circuit on both sides of the insulating layer base steel plate with thickness of 0.2-5mm. It applies to electronic equipment as generally prescribed, such as computers, instruments and dashboards. Because the linear relative density of double panel printed circuit is higher than that of single side aluminum substrate, the volume of machine equipment can be reduced.

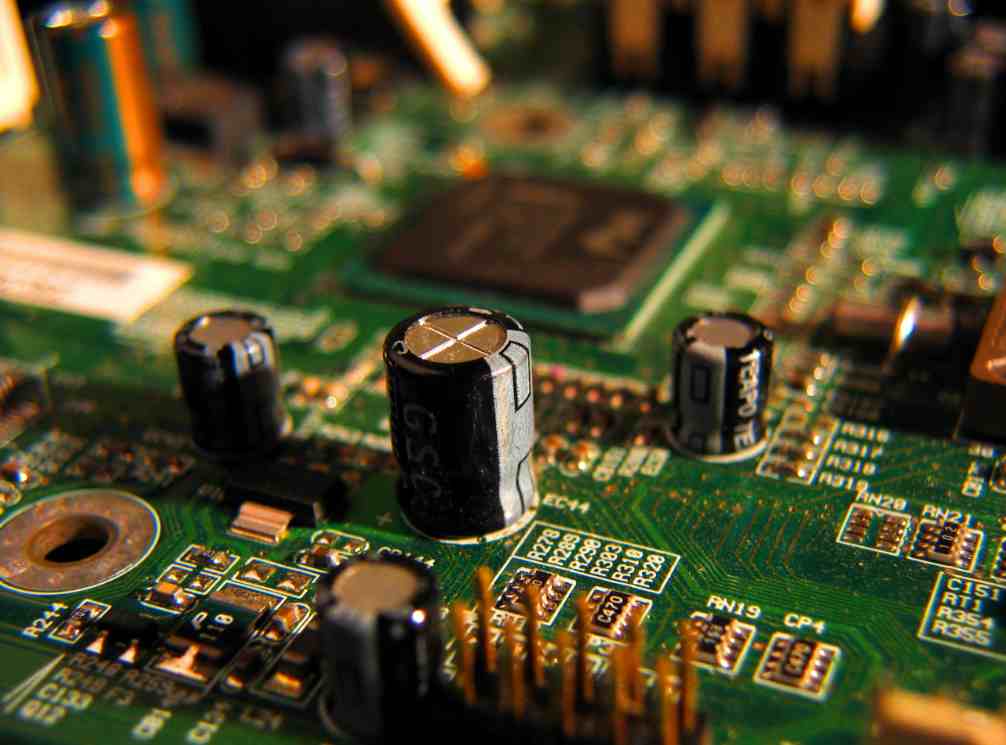

The printed circuit board with three layers printed on the insulating layer base plate is called solid wood multilayer board. This is composed of multiple thin single-sided aluminum substrate or double panel, its thickness is generally 1.2-2.5 mm. In order to find out the power circuit sandwiched in the middle of the insulation layer base steel plate, solid wood multilayer plate installation component holes must be metalized, that is, in the small hole inside the surface layer of metal material, so that it and the printed circuit sandwiched in the middle of the insulation layer base steel plate access.

The following figure is the structure plan of solid wood multilayer board. The common components of solid wood multilayer board are mostly patch components, whose characteristics are as follows:

(1) Cooperate with integrated circuit chip application, can make the whole equipment practical, reduce the net weight of the whole equipment;

(2) Improve the relative density of the wire, reduce the spacing of electronic devices, and reduce the transmission path of data signals;

(3) Reduce the welding points of electronic devices and reduce the repair rate;

(4) Add a shielding layer, the power circuit data signal frame loss reduction;

(5) The introduction of a grounding device heat pipe cooling layer can reduce part of the overtemperature condition and improve the reliability of the whole equipment;

Two, according to the characteristics of the plate classification

According to the characteristics of the board PCB can be divided into rigid and soft two kinds.

Rigid PCB

Rigid printed circuit board has a certain impact toughness, with it dressed as a component with leveling. General electronic equipment is used in the rigidity of the printed circuit board.

Soft PCB

Soft printed circuit boards to soft mylonite plastic or other soft plastic insulating layer material made of board. The components made of it can be bent and telescopic, and can be bent in accordance with installation regulations when applied. Soft PCB is generally used in unique places, such as some digital multimeter display is able to rotate, its internal selection is usually soft PCB; A display, function keys, etc on a mobile phone.

3. Classification by application field

According to the application field can be divided into high frequency circuit board and high frequency circuit board two kinds.

The high frequency of electronic products is the development trend, especially in the wifi network, satellite communication trend, information content products towards high speed and high frequency, and communication products towards large volume and faster wireless data transmission of video, video and statistical data standardization. Therefore, the development trend of the new generation of commodities must be high frequency printed circuit board, its foil plate can be composed of polyneon ethylene, vinyl, polyethylene, polytetrafluoroethylene laminated glass cloth and other raw materials with small dielectric loss and dielectric constant.

Four, unique types of printed circuit boards

At present, there are also some unique printed circuit boards such as metal core printed circuit boards, surface mounted printed circuit boards, carbon film printed circuit boards and so on.

Metal core printed circuit board

Metal material core printed circuit board is to replace a very thin and thick metal sheet with epoxy resin laminated glass cloth board, after a unique solution, so that the gold plate on both sides of the electrical conductor power circuit is connected, and a part of the metal material height width ratio insulation layer. The advantage of metal core printed circuit board is that heat pipe heat dissipation and specification reliability is good, this is because aluminum, iron and other magnetic materials have shielding effect, can avoid dry scratching between each other.

Surface mounted printed circuit board

Surface installation of printed circuit board is able to meet the electronic equipment "light, thin, short, small" must, with each other pin relative density post, low cost surface patch components of the installation and processing technology and design of printing. The printed circuit board has the characteristics of small diameter, small graphic boundary and interval, high precision, and the base steel plate.

Carbon film printed circuit board

Carbon film printed circuit board is in copper plated foil board made of electrical conductor diagram, and then printed a layer of carbon film to produce contact points or jumper (resistance value in line with the requirements of the provisions of the circuit board. Its characteristics are simple production process, low cost, short cycle time, excellent wear resistance, electrical conductivity, can keep the single side aluminum substrate compact, commercial practical, lightweight, suitable for TV, phone, hard disk video recorder and electronic piano and other commodities.