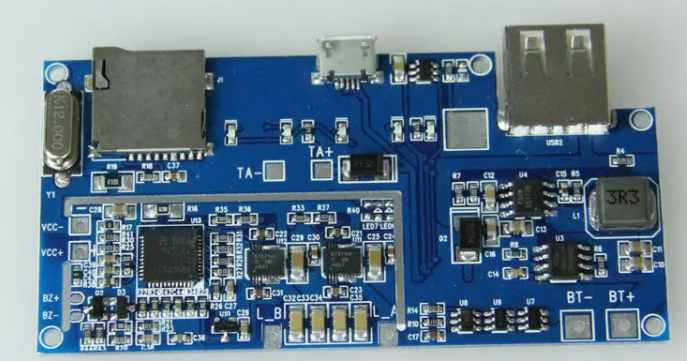

The basic function of circuit board production, printed circuit board refers to the insulation substrate, according to the predetermined design, made of printed circuit board, printed components or a combination of the conductive graphics. A conductive pattern providing electrical connections between components on an insulating substrate is called a printed circuit, excluding printed components. Printed circuit board is one of the important components in the electronics industry. Almost every kind of electronic equipment, from electronic watches and calculators to computers, communication electronics and weapon systems, as long as there are electronic components such as integrated circuits, for electrical interconnection, printed circuit boards are used. In the process of larger electronic product research, the essential success factor is the design, documentation and manufacture of the printed circuit board of the product. The design and manufacturing quality of printed circuit board directly affect the quality and cost of the whole product, and even affect the success or failure of business competition.

It can be said that the use of black PCB is a brand's confidence in RD design and maintenance team, from the side, is also a reflection of the manufacturer's confidence in their own strength. Based on the above reasons make the major manufacturers in the product selection of PCB circuit board design, will be carefully considered. As a result, most of the products with large market shipments in that year adopt red PCB, green PCB or blue PCB board, and only black printed circuit board can be seen in the middle and high flagship products, so customers should not think that black PCB is better than green PCB.

In this case, the instrument has been unable to play a helpful role, you can try to judge the possible range of fault according to the current and voltage, as far as possible to reduce, experienced engineers may be able to quickly judge the fault area, but the specific components which is broken can not be all determined. The only way is to try to replace the suspect component until the problem component is found. Last year, my laptop motherboard was flooded. When I was repairing my master, I also encountered that the fault could not be detected, and I replaced the components three times in the maintenance process, which were power supply chip, diode, USB charging component (that is, the blue laptop jack, which can charge the device when it is off). After that, I replaced the suspicious chip through a wave of detection and investigation. It was determined that a component on the side of the Southbridge chip had short-circuited.

Has been committed to the research and development of printed circuit board manufacturing, adhering to the "customer first, integrity-based", unity and dedication, hard work and enterprising business philosophy, continue to deepen with customers more extensive, more lasting cooperation; Always to customer requirements as the starting point of all work, continuous improvement, with good quality and service back to the customers.

Select the surface treatment process, solder color, character color, solder cover method, copper foil thickness and processing method of PCB circuit board, according to their own requirements for selection, and then the price assessment. After determining the selection factors related to PCB board according to the requirements, the payment method should be selected, including whether to issue bills, what express logistics to choose, packaging type and flying needle test. If there are special requirements, the information should be noted. Synthesize above, can be preliminarily obtained PCB circuit board production price. As a professional manufacturer of PCB circuit boards, users still need to understand and consult with customer service staff after online pricing, so as to avoid losses sometimes caused by system errors and better strengthen the production guarantee of PCB circuit boards.

In the layout, PCB circuit board size is too large, although welding is easier to control, but the printing line is long, impedance increases, anti-noise ability decreases, the cost increases; After hours, the heat dissipation decreases, welding is not easy to control, easy to appear adjacent lines interference with each other, such as the electromagnetic interference of PCB circuit boards. Therefore, PCB design must be optimized. Briefly summarize the production data of PCB industry in the first half of 2014: Japan's shipments in June showed obvious signs of rebound, with the revenue reaching 40.67 billion yen, 5.8% more than the previous month, and the shipments reaching 1.143 million square meters, 4.8% more than the previous month; On a month-by-month basis, both revenue and shipments hit a 2014 high, but when the numbers were compared to the same period last year, shipments were up 7.8% but revenue was down 1.9%. This reflects the increase in shipments due to falling prices. This trend is not unusual for Japan's PCB industry, which mainly produces bu multilayer boards. Shipments are up 8.6 percent this year over the same period last year, but revenue is down 4.1 percent, indicating that prices have fallen as much as 12 percent over the past 12 months. As local demand for PCB boards is limited to mobile phones, PCB makers have to undercut their competitors and attract a limited number of customers.