Nowadays, people's life is increasingly inseparable from electronic products, which also makes China's electronic industry has been growing continuously, and the integrated circuit industry has developed rapidly. The demand for pcb circuit boards is only increasing, the market demand is large, circuit board manufacturers also emerge in endlessly, for buyers, there are more opportunities to choose, but from this, in the many manufacturers, how to choose a high-quality circuit board manufacturers, has become a headache. The following to explain how to choose high quality pcb manufacturers and patch processing how to choose hot melt adhesive matters needing attention related knowledge.

1. How to choose hot melt adhesive for patch processing

kingford hot melt adhesive is to use the heat of the hot melt adhesive machine to melt the hot melt adhesive, the dissolved adhesive becomes a liquid, and then the hot melt hose and hot melt adhesive gun are sent to the surface of the adhesive, and the adhesive is completed after cooling. The following take you to understand how to choose hot melt adhesive and hot melt adhesive use precautions:

First, the color choice of glue.

If the object itself has no special requirements for color, it is recommended to use yellow hot melt adhesive. In general, yellow hot melt adhesive is better than white adhesive.

Two, by the surface treatment.

To be followed by the surface of the dust, oil should be handled clean, in order to make the hot melt adhesive better play the bonding role.

Three, operation time.

Fast operation is a major feature of hot melt adhesive. The working time of hot melt adhesive is generally about 15 seconds. With the wide application of modern production mode -- assembly line, the working time of hot melt adhesive is becoming shorter and shorter, such as book binding and sound box manufacturing, the working time of hot melt adhesive is about 5 seconds.

Four, temperature resistance.

SMT patch processing experts say hot melt adhesive is more sensitive to temperature. When the temperature reaches a certain degree, the hot melt adhesive begins to soften. When the temperature is lower than a certain temperature, the hot melt adhesive will become brittle. Therefore, the selection of hot melt adhesive must fully consider the temperature change of the environment where the product is located.

Five, viscosity.

The viscosity of hot melt adhesive is divided into early viscosity and late viscosity. Only the early viscosity and late viscosity is consistent, in order to keep the hot melt adhesive and the substrate stable. In the production process of hot melt adhesive, it should be guaranteed to have oxygen resistance, halogen resistance, acid and alkali resistance. Being followed by different materials, hot melt adhesive play is also different, therefore, should be based on different materials to choose different hot melt adhesive.

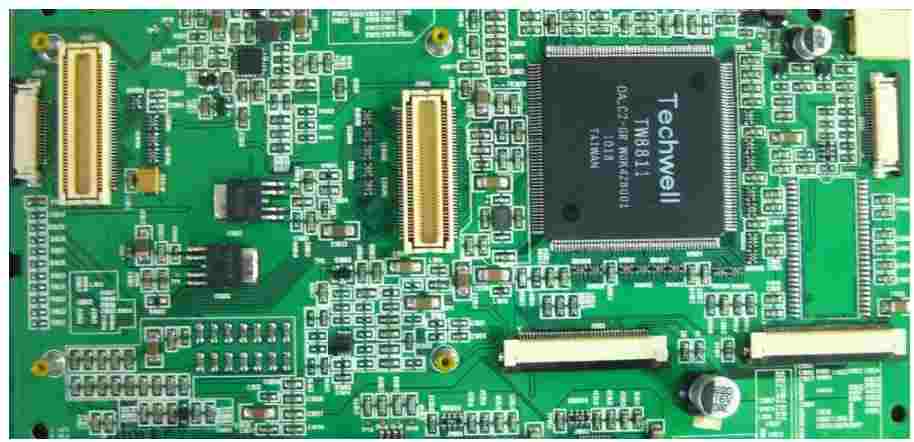

2. How to choose high-quality pcb manufacturers

Nowadays, people's life is increasingly inseparable from electronic products, which also makes China's electronic industry has been growing continuously, and the integrated circuit industry has developed rapidly. The demand for pcb circuit boards is only increasing, the market demand is large, circuit board manufacturers also emerge in endlessly, for buyers, there are more opportunities to choose, but from this, in the many manufacturers, how to choose a high-quality circuit board manufacturers, has become a headache. kingford focuses on pcb circuit board, smt processing and production, has rich experience, the following will teach you how to choose high-quality pcb circuit board manufacturers:

First, look at the product

There are many kinds of pcb circuit boards, in the process and production research and development, all need to a variety of high-end technical support. In order to know whether the products produced by the manufacturer meet our procurement needs, we can first ask the manufacturer to provide some samples of pcb circuit boards. We can judge the strength and professionalism of the manufacturer by the quality of these samples.

Two, look at the application

pcb circuit board can be used in all walks of life, a high quality circuit board manufacturer, the production of circuit board products should not be single, it should be able to provide different products for different industries demand. kingford has independent production and research capacity, professional engineers and advanced production process, can provide customers with PCB solutions of different industries, products can be used in military research, power electronics, industrial production, communications, medical, security, automotive and other industries, involving a wide range of fields.

Three, listen to the sound

The voice of customer feedback will more truly reflect the strength of the manufacturer, service and other aspects. Therefore, before determining whether to choose this circuit board manufacturer, you can search the information of relevant enterprises on the Internet to see whether there is bad negative information. If there is, you need to choose carefully. With more than ten production and research and development experience, Jingbang Technology has established a flexible system platform that ADAPTS to the design, production and service of multi-variety and small-batch products, and has established a good cooperative relationship with nearly ten thousand customers in more than 30 countries around the world, which has been unanimously praised.

Four, look at the reputation

The reputation of pcb circuit board manufacturers can be reflected in many aspects, such as the business license of enterprises, certificates of honor, cooperative customers, etc., from the perspective of various factors. In addition, we can also know whether the manufacturer has a good reputation and whether it can do what it says through its commitment to customers. Jingbang Technology is a private technology enterprise recognized by Shenzhen Science and Technology Bureau. It is an excellent supplier recognized by many well-known enterprises at home and abroad. With high reputation, it can promise fast delivery within 3 days and guarantee quality and quantity. Five, see the service of good pcb circuit board manufacturers, of course, need to have good service. The purchase of pcb circuit boardneeds to involve many issues, such as product process, product use, product warranty, etc., need to have a perfect service system. And the pre-sale service we can communicate with the manufacturer to see whether we can give customers detailed product introduction, whether we can be patient and quickly solve customer problems. After-sales service is to see whether the manufacturer can provide package return, warranty, technical guidance and other problems that may be encountered in the later period.