What are the advantages of SMT mounters?

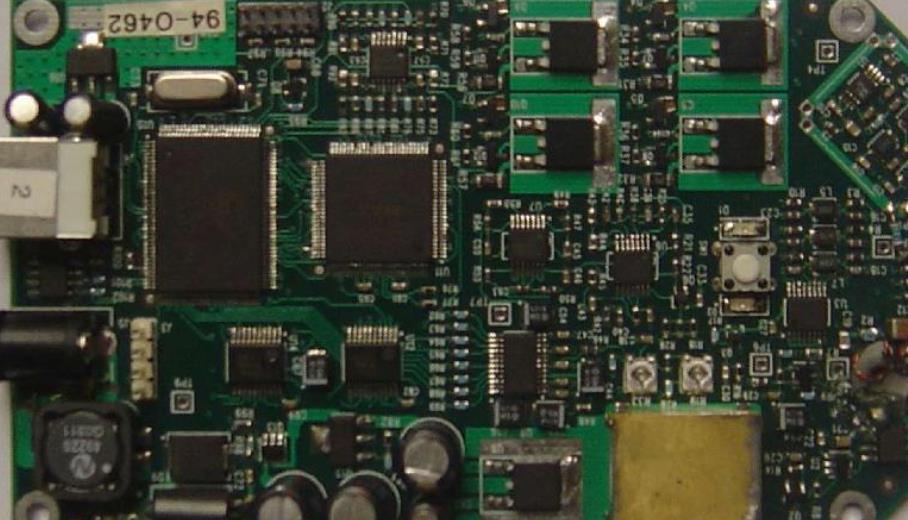

SMT is surface mount technology, which is the most popular technology and process in the electronic assembly industry Electronic circuit surface mount technology (SMT) is called surface mount technology It is a kind of surface assembly components with no leads or short leads (SMC/SMD abbreviation, chip components in Chinese) mounted on the surface of a printed circuit board (Printed Circuit Board, PCB) or the surface of other clusters Circuit assembly technology using reflow or dip welding for welding and assembly

1. What are the advantages of SMT?

SMT was born with the development of the electronic industry,

Circuit board

With the development of electronic technology, information technology, and computer application technology The rapid popularization of surface mount technology is due to its following advantages

1) It is easy to realize automation and improve production efficiency.

2) High assembly density of components, small volume and light weight of electronic products.

3) High reliability. Automatic production technology ensures reliable connection of each welding point At the same time, because the surface mount components (SMD) are firmly installed on the PCB surface, they have high reliability and impact resistance Powerful

4) Good high frequency characteristics. Surface mount components (SMDs) have no pins or segment pins, which not only reduces the impact of distribution characteristics, but also firmly attach and weld to the PCB surface, greatly reducing the parasitic capacitance and inductance between leads, thus greatly reducing electromagnetic interference and radio frequency interference, and improving high-frequency characteristics.

5) Reduce costs. SMT adds PCB wiring density, reduces the number of holes, reduces the area, and reduces the number of PCB layers with the same functions, all of which reduce the manufacturing cost of PCB. Lead free or short lead SMC/SMD saves lead information, omits trimming and bending processes, and reduces equipment and labor costs. The improvement of frequency characteristics reduces the cost of RF debugging. The size and weight of electronic products are reduced, thereby reducing the overall cost. Good welding reliability will naturally reduce maintenance costs.

2. What is the basic process of SMT?

The basic process components of SMT include: printing (red glue/solder paste) ->inspection (optional AOI automatic or visual inspection) ->placement (first paste small components, then paste large components: high-speed placement and integrated circuit installation) ->inspection (optional AOI optical/visual inspection) ->welding (welding with hot air reflow welding) ->inspection (can be divided into AOI optical inspection, appearance and functional test inspection) ->maintenance (Tools: welding station and hot air desoldering station, etc.) ->plate splitting (plate cutting by manual or plate splitting machine)

1) To form an SMT production line, there must be 3 kinds of important equipment: printing machine removing machine, mounter, reflow over wave soldering machine Among them, with the development of surface mount technology, the large number of applications of bottom lead integrated circuit packaging BGA QFN has become more and more efficient