Common defects and solutions of SMT dispensing

Painting

Drawing/trailing is a common defect in gluing The common reasons are that the inner diameter of the glue nozzle is too small, the dispensing pressure is too high, the distance between the glue nozzle and the printed circuit board is too large, the patch adhesive is expired or the quality is poor, and the reasons are too small The viscosity of the flake glue is too high, the glue cannot be recovered to room temperature after it is taken out of the freezer, and the amount of glue is too large

Solution: replace the rubber nozzle with larger inner diameter; Reduce the distribution pressure; Adjust the "stop" height; Replace the glue and select the glue with proper viscosity; It should be restored to room temperature (about 4h) before being put into production; Adjust this amount of glue

The rubber nozzle is blocked

The fault is that the amount of glue from the nozzle is too small or there is no glue spot. The reason is usually that the pinhole is not completely cleaned; Impurities are mixed in the patch adhesive, causing blockage; Mixed with incompatible glue.

Solution: Replace the clean needle; Replace the high-quality patch adhesive; The brand of the patch adhesive should not be mistaken.

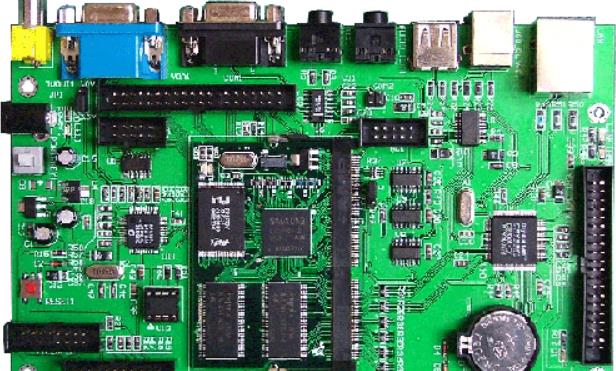

Polychlorinated biphenyls

Empty play

The phenomenon is that there is only dispensing action, but no glue amount. The reason is that there are bubbles in the patch adhesive; The rubber nozzle is blocked.

Solution: Remove the glue in the syringe (especially the glue installed by yourself); Replace the glue nozzle.

Parts shift

The phenomenon is that after the repair adhesive is cured, the component moves. In serious cases, the component pin is not on the pad. The reason is that the amount of adhesive is uneven. For example, there is more adhesive at two points of the chip module and less adhesive at the other point;

The component shifts during the chip or the initial adhesion of the patch adhesive is low; The PCB is placed for too long after glue is placed Glue is semi cured

Solution: Check whether the rubber nozzle is blocked and eliminate the uneven glue discharge; Adjust the working state of the mounter; Replace the glue; Placement time after monitoring should not be too long (less than 4h)

The first smt patch processing is tested and tested

The first piece inspection of smt patch is very important. As long as the component specification, model and first article polarity are correct, the machine will not place the wrong components in the subsequent mass production process: as long as the first article placement position meets the general placement deviation, the machine can ensure the repeatability in the mass production process Therefore, the smt processing plant must carry out the first article inspection every shift, every day, and an inspection (test) system must be established

1. Program commissioning

Program commissioning usually adopts the method of non installed components (dry running). If the test runs normally, can it be formally installed?

2. First try sticker

1. Call up the program file.

2. Try to install the printed circuit board according to the operation rules

3. First article inspection

Inspection items

1. Whether the specification, direction and polarity of the parts on the bit number of each part are consistent with the process file (or surface assembly sample).

2. Check whether components are damaged and pins are deformed.

3. Whether the deviation between the component installation position and the gasket exceeds the allowable range.

Inspection method

The inspection method shall be determined according to the configuration of inspection equipment of each unit.

Common pitch components can be visually inspected, and magnifying glass, microscope, online or offline optical inspection can be used for high-density and narrow pitch

Check each (AOD).

Inspection standard

The SMT processing plant shall implement according to the company standards formulated by the device or other standards (such as IPC standards or SUT10670-1995 General Technical Requirements for Surface Assembly Process).

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.