SWOT analysis of surface roughness patch market and SMT dip angle

SWOT Analysis and Forecast of SMT Chip Market

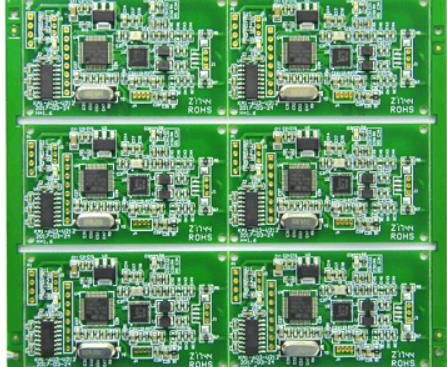

The SMT Patch Testing Equipment Market Forecast Report 2021-2027 provides a brief overview of current trends, growth opportunities and industry constraints The report provides key information about the outstanding advantages of SMT SMT chip test equipment manufacturers in the market, and provides valuable guidance and guidance for companies and individuals interested in the industry The report focuses on the current market situation of the surface roughness patch, the demand situation of the surface roughness patch, the business strategies used by the main participants, and the important factors of the future prospects of the industry

SWOT Analysis and Forecast of 2021 SMT Chip Market

It is estimated that the market of surface roughness patch testing equipment will grow at a compound annual growth rate of 4.1%, and the revenue in the forecast period will reach 450.95 million dollars.

The main purpose of the market report on surface roughness patch testing equipment is to provide detailed information about the industry on the basis of a detailed and in-depth evaluation of the business. According to the type and use, the natural refrigerant market is appropriately divided into important market segments. It also provides a detailed industry overview of the market size of surface roughness patch testing equipment.

Breakdown by type:

-Electronic consumption

Equipment Telecommunications

-Automobile

-LED

Screen medical equipment aviation

Aerospace-

Military/Defense

The main points of SMT discussed in the report are the main market participants involved in the market, such as manufacturers, raw material suppliers, equipment suppliers, end users, traders, distributors, etc. A complete overview of the company is mentioned. The report also includes production capacity, output, price, revenue, cost, gross margin, gross margin, sales volume, sales revenue, consumption, growth rate, import, export, supply, future compliance and the ongoing development of surface roughness patch technology.

SMT Inclination Processing Flow

We can simply understand the tilt angle, which is a link in the electronic manufacturing process. There are manual tilt angle, tilt angle piece and AI machine tilt angle, tilt angle piece. Inserts the specified data into the specified location. Manual tilt angle, tilt angle pieces must also be wave soldering to weld electronic components on the circuit board.

Tilt angle, tilt angle (DIP), also known as tilt angle, tilt angle package, or DIP technology in Chinese, refers to integrated circuit chips packaged in the form of DIP. Most small and medium-sized integrated circuits use it for such packaging, and the number of pins usually does not exceed 100. The CPU chip packaged with tilt angle and tilt angle has two rows of pins, which need to be inserted into the chip slot with tilt angle and tilt angle structure. Of course, it can also be directly inserted into the circuit board with the same number of welding holes and geometric shapes for welding. Tilt angle, the tilt angle package chip shall be inserted and pulled out from the chip socket with special care to avoid damage to the pins. Inclination, inclinations Packaging structures include: multilayer ceramic dual in-line, single-layer ceramic dual in-line, lead frame inclination, inclinations (including microcrystalline glass sealing type, plastic packaging structure type, ceramic low melting point glass packaging type), etc.

The process flow of the processing of the tilt angle parts can generally be divided into: assembly molding processing - assembly - wave soldering - assembly leg cutting - repair welding (after welding) - cleaning plate - function test

Now, with the surface roughness processing technology, the surface roughness wafer processing has a tendency to gradually replace the tilt angle and tilt angle processing However, due to the large size of some electronic components in polychlorinated biphenyl production, the parts have not been replaced and are still in electronic assembly Processing plays an important role Inclination, inclination piece processing After surface roughness patch processing, assembly line manual pieces are usually used, which requires more staff

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.