Different Surface Mount Machines and Their Characteristics

Select SMT to place the machine with different speeds

Before selecting and purchasing SMT mounters, we will have a certain understanding, and then select the appropriate SMT mounter itself according to the comparison of various information. However, in the SMT mounter processing industry, there are many different models of SMT mounters, and we cannot decide which model is suitable for you. Let's briefly introduce the full-automatic mounter

First of all, the structure of the machine is different: the slow SMT laminating machine has an arc structure, which is relatively simple in structure, poor in installation accuracy, small in floor area, and low in environmental requirements The structure of high-speed SMT assembly machine is more complex than that of turntable, which can meet the installation accuracy of microchip modules and realize high-speed installation

Secondly, the charging speed is different: generally speaking, in the medium and low speed mounters, the theoretical charging speed is about 5000-30000 points/hour; The theoretical loading speed of high-speed machines is generally 30000-60000 pieces per hour.

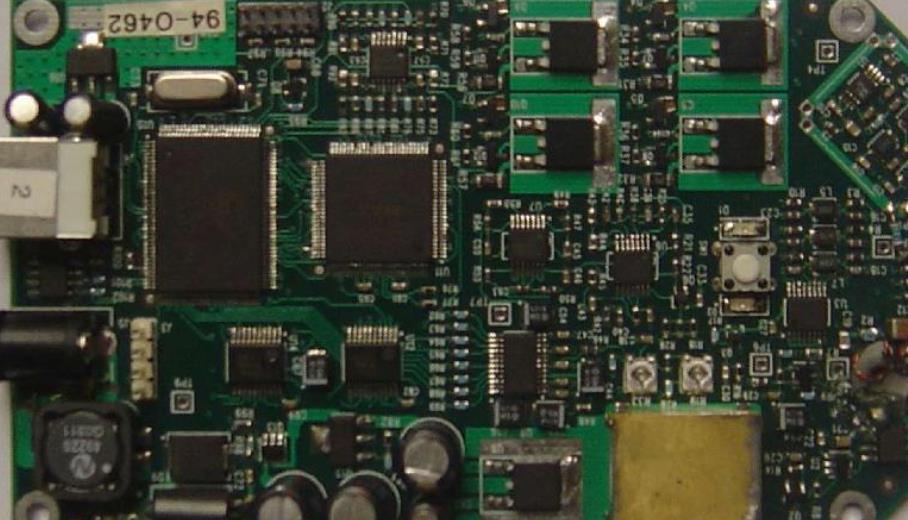

Circuit board

3. SMT products: there are many types of low and medium speed SMT machines, mainly used for large parts, high-precision parts and special parts, and also can install small chip parts; High speed surface mount technology is mainly used to assemble small chip modules and small embedded modules.

Fourth, the scope of application of SMT: ordinary SMT machines are widely used in some small and medium-sized electronic product production and processing enterprises, as well as a variety of product design centers and small batch production enterprises. High speed mounting machine is mainly used in large electronic manufacturing companies and some professional original equipment manufacturing companies.

Six characteristics of the mounting machine

The mounter can install the required high-precision components and large mechanical equipment on the components or different types of components, and can cover almost all components, which is called multi-functional mounter or universal mounter. Multifunctional chip mounter can process various complex parts, and is an indispensable part of complex electronic equipment production.

1: The structure of SMT mounting machine adopts arch structure, which is characterized by high precision and good flexibility.

2: SMT mounter mainly uses fixed circuit board, which is realized by moving the X and Y positions of the magnetic head, rather than caused by the movement of inertial worktable and large displacement or heavy parts.

3: SMT mounter can accept the packaging pipeline of all materials, such as tape packaging, tube packaging, box packaging and pallet packaging. In addition, when there is more material on the tray, a special multi-layer tray feeder can be installed.

4: In addition to traditional vacuum nozzles, special nozzles can also be used for parts with special shapes to avoid breathing difficulties. In addition, the pneumatic handle can be used for the vacuum nozzle assembly

5: In the calibration of mounter mounter components, the inverted camera, light source, side lamp, backlight, direct plug-in headlamp and other functions that can identify each component are usually used. If the size of the component is too large to exceed the field of view of the GG camera, the aerial camera can also be analyzed and corrected by shooting multiple videos. Some universal installation machines are also equipped with movable mounting head monitors that can identify various smaller components.

6: SMT placement machine cannot be compared with the high speed playing machine The speed of the high-speed SMT placement machine part installed in the speed component of the small chip can reach the multi functional machine The installation size is 5 to 10 times that of the same project. Therefore, in large and medium-sized production, reasonable configuration is usually carried out according to the characteristics of the product, so that the efficiency of each equipment is close to higher

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.