Basic knowledge and methods for testing soft and hard composite plates?

What are the basic knowledge and methods of testing soft and hard composite boards that PCB manufacturers, PCB designers and PCBA manufacturers explain to you?

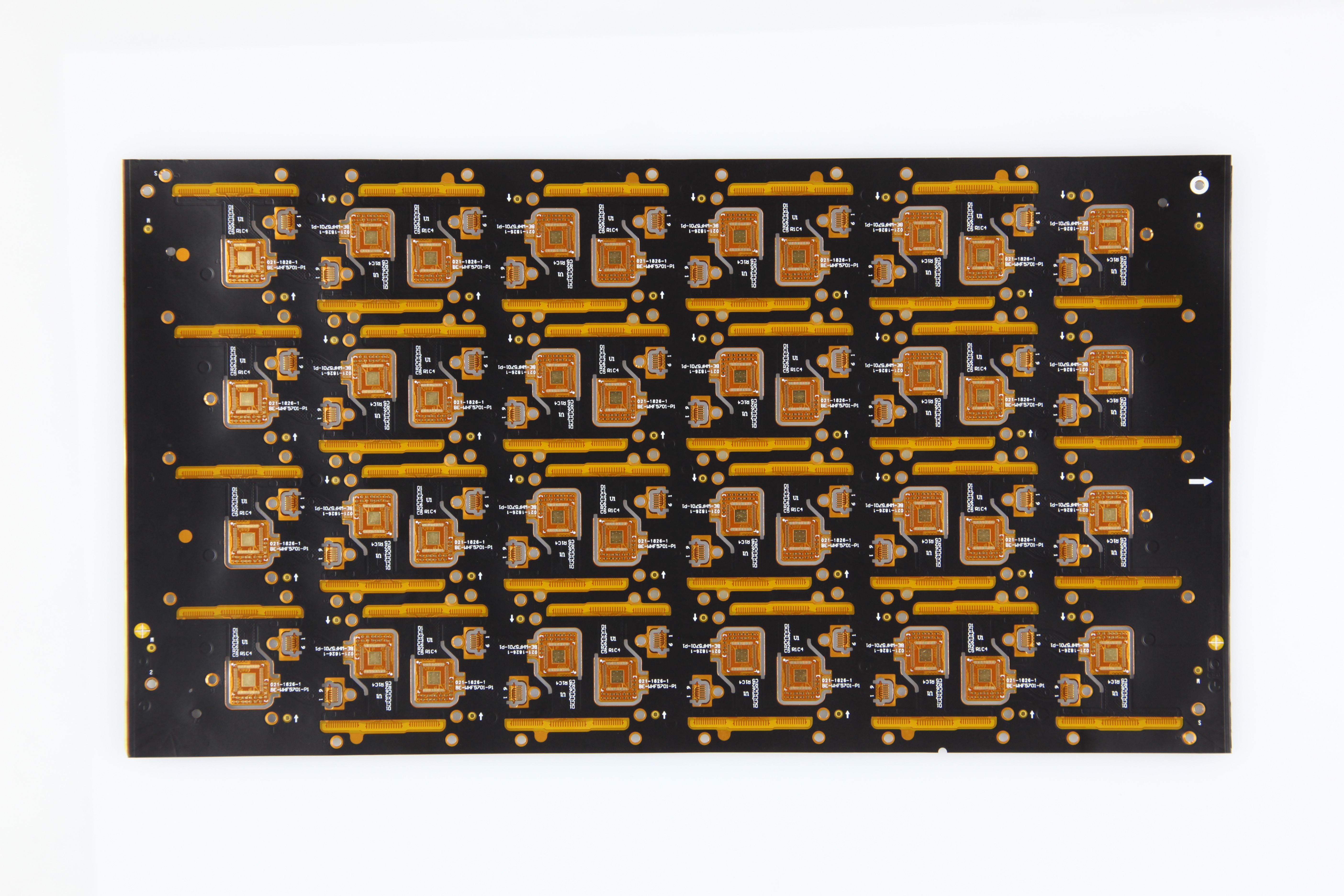

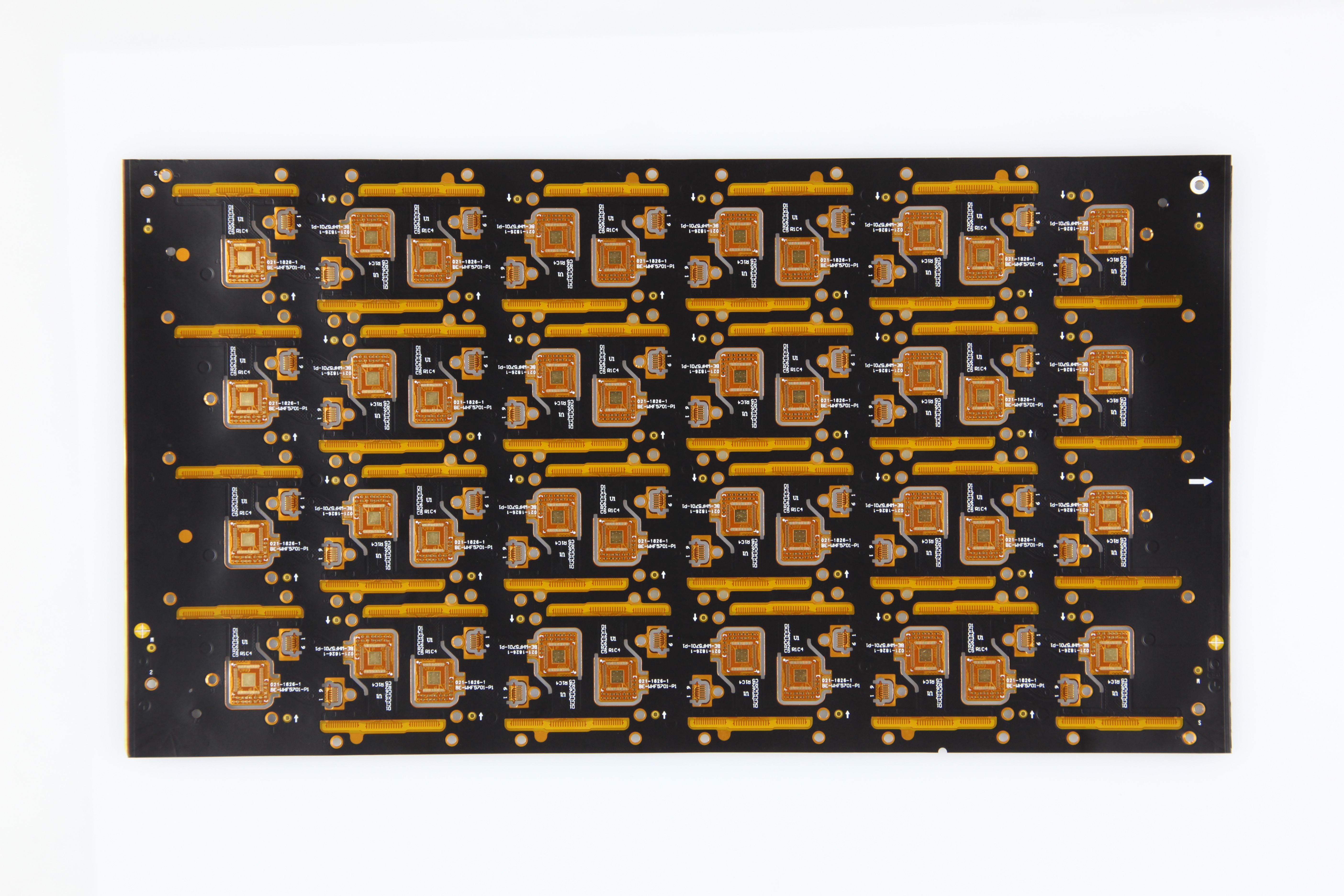

The reason why the PCB we have come into contact with in our life can be used more and more widely is that its unique advantages such as high reliability, high-density, designability, and producibility are closely related. The demand for PCB has been growing rapidly for many years in terms of output and performance indicators. Accordingly, higher requirements have been put forward for PCB quality inspection, The traditional detection methods can no longer meet the requirements of the quality control in the soft and hard bonding plate industry. As an important part of modern electronic equipment, PCB is required to further improve its integration due to its small size and high installation density. The quality of PCB directly affects the quality of the entire electronic products, so PCB detection equipment is particularly important and critical. PCB testing is an inspection method to find problems in time, and also a necessary means to prevent more defective products and reduce losses.

When testing PCB boards, we should pay attention to the following points:

1. Test PCB to avoid short circuit between pins

2. Pay attention to the insulation performance of electric soldering iron when testing PCB board

3. The internal resistance of PCB testing instrument shall be large

4. Pay attention to heat dissipation of power integrated circuit when detecting PCB

5. The lead wire of PCB board shall be tested reasonably

6. Ensure the welding quality when testing PCB

7. Do not easily judge the damage of integrated circuit when detecting PCB board

8. Understand the working principles of integrated circuits and related circuits before testing PCB boards

What should be done before testing the soft and hard composite plates? First, understand the working environment of the equipment, mainly considering the possible impact of external electrical parameters on the equipment; Ask what happens when the circuit board fails, and analyze the cause of the failure; Check the components on the circuit board carefully to find out which components play a key role in the circuit board; Anti electromagnetic, static and other interference measures shall be taken.

So, what are the common inspection methods for PCB in the production process? In addition to the high cost of manual visual inspection, certain errors are generated due to long time visual inspection. In addition to the reduction of wire spacing and component volume on PCB, the requirements for manual visual inspection are also increasing. Obviously, with the continuous sharp increase of PCB output, this method is more and more unsuitable; Another is PCB function test. This function system test uses special test equipment at the middle and end of the production line to comprehensively test the functional modules of the circuit board to confirm the quality of the circuit board. It requires special equipment and specially designed test process, and the writing of functional test program is complex, so it is not suitable for most circuit board production lines. But nowadays, there is a kind of size detection that is relatively applied more. It uses anime image measuring instrument to measure hole position, length and width, position and other dimensions. As the soft and hard bonding plates are small, thin and soft products, the contact measurement is easy to deform and cause inaccurate measurement, so the anime image measuring instrument has become the choice of high-precision dimension measuring instruments.

It is precisely because PCB has a wide range of applications in today's society, so for the questions that may arise in the PCB testing process, I would like to tell you some practical and operable methods summarized through years of testing, and provide them to you in the above way, hoping to provide a useful reference for you in the practice of PCB testing. What are the basic knowledge and methods of testing soft and hard composite boards that PCB manufacturers, PCB designers and PCBA manufacturers explain to you?