Two drilling methods can be selected for PCB drilling. One is to use a numerical control drill to drill, but it is particularly easy to burn the main shaft. The advantage of drilling with a drill is that the hole wall drilled is very smooth, without burrs, and has high accuracy. The second is to use a gong machine to drill, but it is easy to have burrs, and the precision is not that high, and the drilling is easy to deviate. Therefore, the cost of aluminum substrate is a little higher than that of aluminum substrate, Because the damage to the drilling rig is relatively large.

In addition, there is no difference between single-sided aluminum substrate and FR4 single panel

The double-sided aluminum substrate needs to be pressed first, and then the rest is the same as the FR4 double panel

The aluminum substrate is similar to the single-sided PCB used for FR4, mainly because there is no electroplating process.

FR4 plate

FR4 board is a code for the grade of fire-resistant material, which means that the resin material must be able to extinguish itself after burning. It is not a material name, but a material grade. Therefore, there are many kinds of FR-4 materials used for general circuit boards, But most of them are composites made of so-called Tera Function epoxy resin, filler and glass fiber.

FR-4 epoxy glass cloth laminate is generally called FR-4 Epoxy Glass Cloth, insulating board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4, glass fiber board, glass fiber board, FR-4 reinforcement board, FPC reinforcement board, flexible wiring board reinforcement board, FR-4 epoxy resin board, flame retardant insulation board, FR-4 laminate, epoxy board, FR-4 optical board, FR-4 glass fiber board, epoxy glass cloth board Epoxy glass cloth laminate, PCB drilling pad. Main technical features and applications: stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance standard, suitable for products with high-performance electronic insulation requirements, such as FPC reinforcement board, PCB drilling pad, glass fiber meson, potentiometer carbon film printed glass fiber board, precision planetary gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation brace partition, insulation pad, transformer insulation board Motor insulation parts, grinding gears, PCB switch insulation boards, etc.

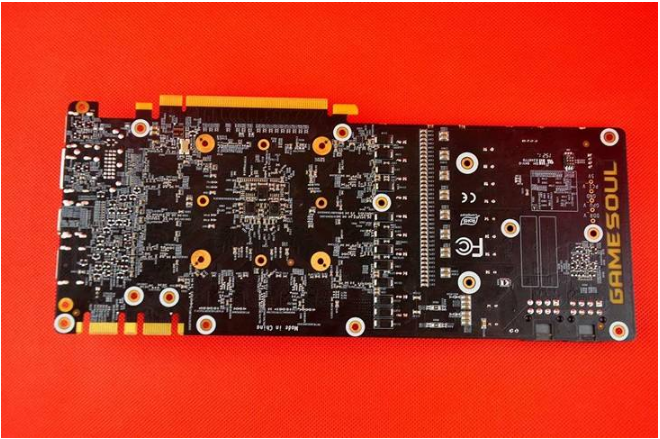

Aluminum substrate is a kind of metal based copper clad laminate with good heat dissipation function. Generally, a single panel is composed of three layers, namely circuit layer (copper foil), insulation layer and metal base layer. For high-end use, PCB is also designed as double-sided board, with the structure of circuit layer, insulation layer, aluminum base, insulation layer and circuit layer. Very few applications are multilayer boards, which can be made of ordinary multilayer boards, insulating layers and aluminum bases.

The LED aluminum substrate is PCB, which is also the meaning of printed circuit board. However, the material of the circuit board is aluminum alloy. Previously, the material of our general circuit board was glass fiber. However, because LED has a large heat, the circuit board for LED lamps is generally aluminum substrate, which can conduct heat quickly. The circuit board for other equipment or electrical appliances is glass fiber board.