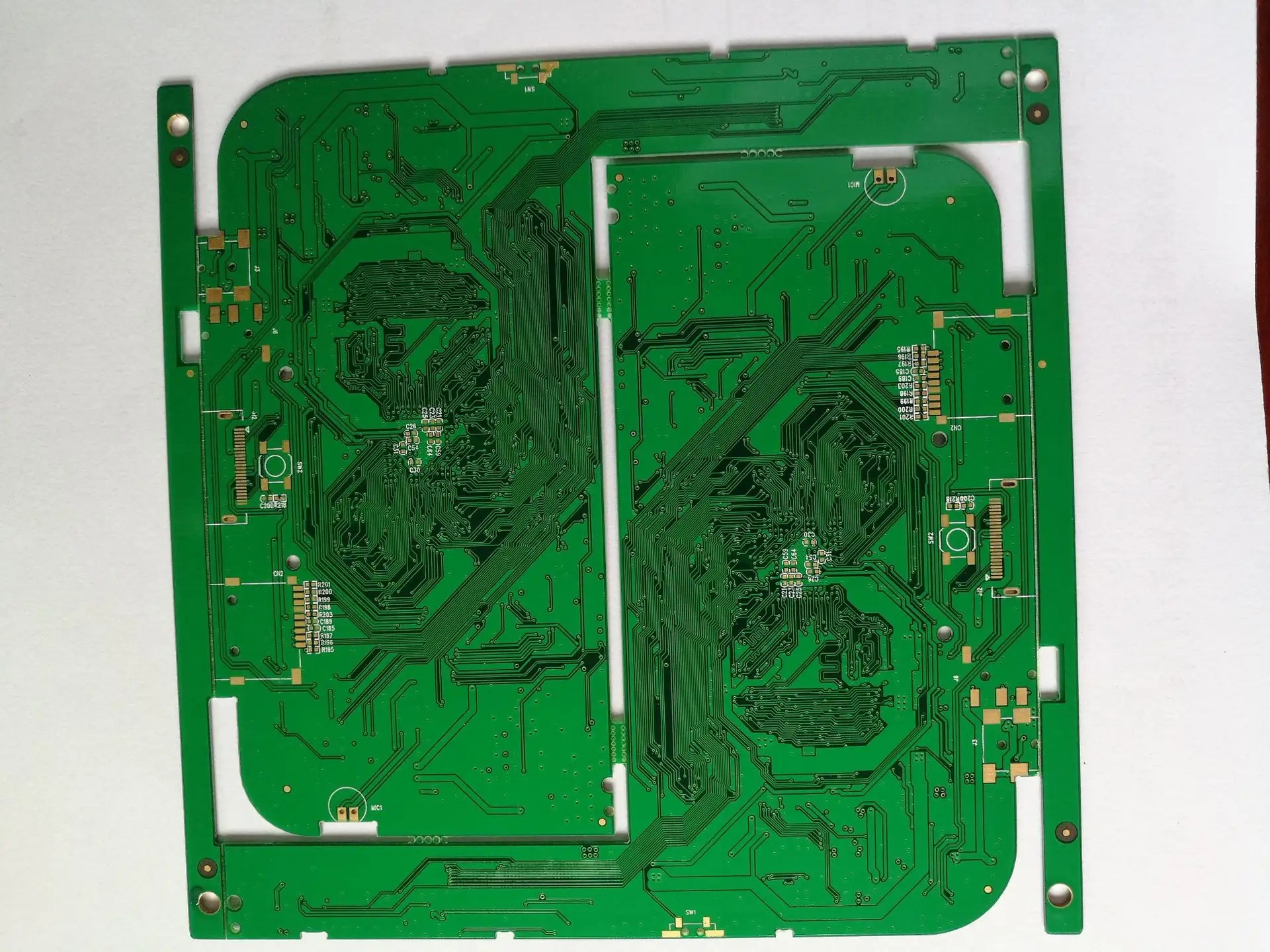

PCB processing is no longer abnormal, and the industry focuses on pcb production

PCB manufacturers, PCB designers and PCBA manufacturers explain that PCB processing is no longer abnormal, and the industry focuses on PCB production

Whether there are so many days and nights when we are worried about the abnormal condition of PCB processing. Behind every employee who is anxious about the board delivery date, there is a customer who urges us. Today, let's analyze how to deal with the abnormal condition of PCB processing, to solve the customer's doubts and worry for us.

PCB processing is no longer abnormal, and the industry focuses on pcb production

It is inevitable to encounter several defective products during PCB processing, which may be caused by machine errors or human factors. If the hole breaking state is a phenomenon of point distribution rather than a whole circle of circuit breaking, it is called point hole breaking, or "wedge hole breaking". The common cause is the poor treatment of the glue removal slag. During PCB processing, the adhesive residue removal process will be treated with bulking agent first, followed by the erosion of strong oxidant "permanganate". This process will remove the adhesive residue and produce microporous structure. The oxidant left in the removal process depends on the reductant for removal, and the typical formula uses acidic liquid for treatment.

As the problem of residual rubber residue will not be seen again after the treatment of rubber residue, most people often neglect the monitoring of reducing acid solution, which may leave the oxidant on the hole wall. After that, the circuit board enters the chemical copper manufacturing process. After the pore forming agent treatment, the circuit board will undergo micro etching treatment. At this time, the residual oxidant will be soaked in acid again, causing the resin in the residual oxidant area to peel off, which is equivalent to destroying the pore forming agent.

PCB processing is no longer abnormal, and the industry focuses on pcb production

I wonder if you have any idea about these exceptions in the processing of circuit boards. Our customers are always worried about the scrapping of boards. If there are problems, we should analyze them first and then solve them. The delivery date is slow? What causes slow delivery? Each of our operators and our dear customers need to know what exceptions to prevent during PCB processing.

Of course, we need to strictly control every link in the PCB processing process, because chemical reactions sometimes occur slowly in the corners we do not pay attention to, thus damaging the entire circuit. We should be alert to this situation.

When our board making personnel understand the abnormalities that will occur in PCB processing, they will be more careful in each process of PCB processing. After our customers understand these, they will also be more careful in PCB processing, not just blindly processing, but processing for quality.

PCB manufacturers, PCB designers and PCBA manufacturers explain that PCB processing is no longer abnormal, and the industry focuses on PCB production.