Factors determining SMT processing quotation in PCB production

The importance of SMT chip processing in the smt processing industry is irreplaceable. Many enterprises and R&D groups that have to produce electronic components on a commission basis are not familiar with how to calculate the SMT co processing cost. How to calculate the SMT co processing cost?

How did this price come about? Many friends who do not know about PCBA chip processing plants will feel that they are in a fog. In fact, the production and processing stage of SMT is relatively complex, and the latest quotation will be affected by a variety of factors. Now, let's talk about the calculation method of SMT processing price.

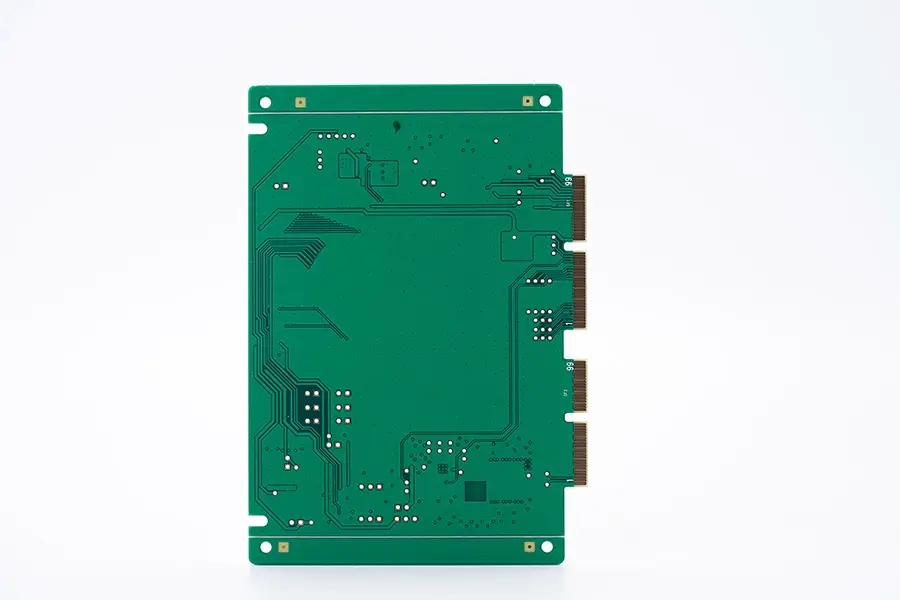

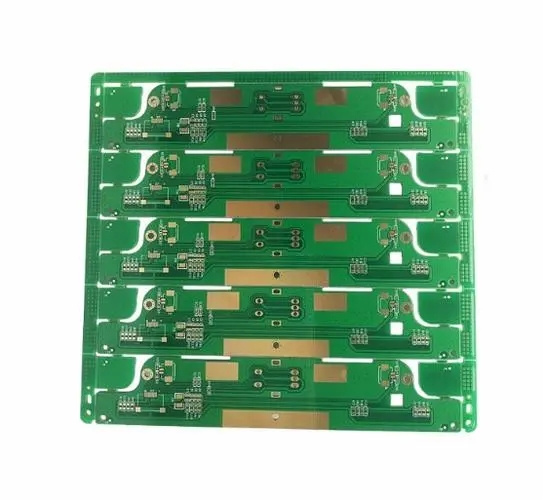

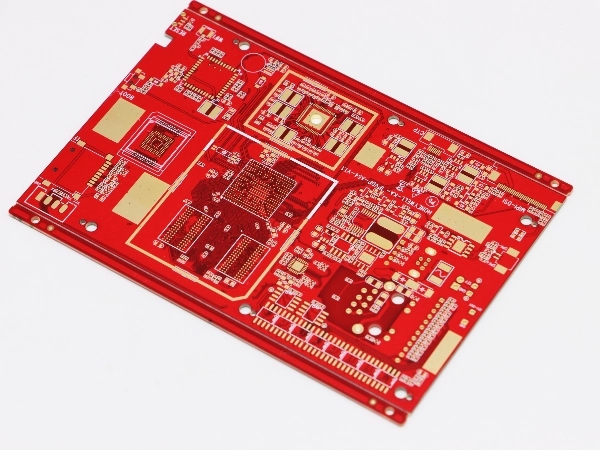

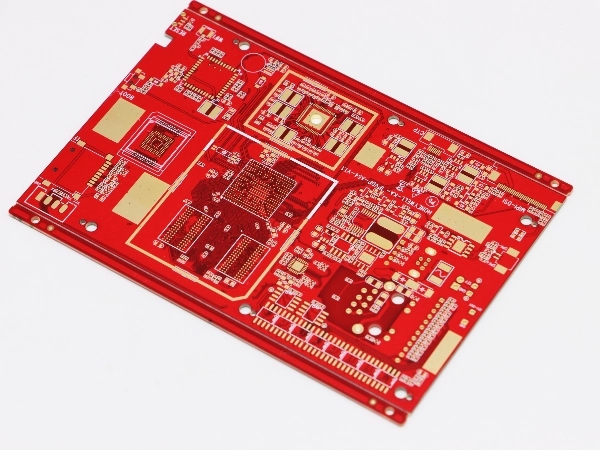

Some enterprises calculate one pad as a point, but two welding points as a point. Take the pad calculation as an example, which is to calculate the total amount of pads on the PCBA board. However, for some special components, such as inductance, large capacitance, integrated circuit, etc., the rated power must be calculated.

Unit price of solder joint:

In the current market, the unit price of solder joints varies from 0.008 to 0.03 yuan/solder joint. The key factors are as follows:

1、 Process

1. Lead technology is relatively cheap;

2. The lead-free process is relatively high;

3. Red glue SMT patch processing is relatively simple;

4. Solder paste red glue double process is relatively troublesome.

2、 Total

1. The total amount of common SMT chip proofing agent processing is small, as long as the total amount of a few to dozens of pieces, this will be based on the minimum consumption to replace the cost of processing, not calculated by points; 2. For small batch SMT chip processing, if the number of SMT chips is less than 1000, it will be calculated according to the combination of project cost and points; 3. Large batch SMT chip co processing, counting points × Unit price calculation.

3、 Degree of difficulty coefficient

1. Classified by single and double sides, single side is cheaper, and double side is a little more expensive; 2. In terms of precision, more precise SMT patch processing, such as BGA, will be a little more expensive; 3. Divided according to the density of SMD components.

4、 Proofing

SMT chip processing orders are SMT chip proofing orders with less than 100 pieces. The degree of difficulty coefficient of the board, the time to do the program, and the time to go on the machine and transfer to the line are different, and the engineering fees ranging from 800 yuan to 3000 yuan are charged.

5、 Steel mesh

Open steel meshes of different specifications according to the size of PCB. According to the precision of the chip on the PCBA board, choose to turn on electric polishing steel mesh or ordinary steel mesh. The cost of different steel mesh specifications and types is about 120~350. Of course, customers can also provide steel mesh by themselves.

PCB manufacturers, PCB designers and PCBA manufacturers explain the key factors that determine SMT processing quotation.