Electromagnetic compatibility design is closely related to specific circuits. In order to conduct electromagnetic compatibility design, PCB designers need to minimize radiation (RF energy leaked from products) and enhance its susceptibility to radiation (energy entering products) and anti-interference ability. For the common conductive coupling at low frequencies and the common radiation coupling at high frequencies, it is necessary to pay full attention to cutting off the coupling path in the design. This article mainly explains the points that should be paid attention to in order to reduce the electromagnetic interference problem in PCB.

PCB design principles

As the circuit board integration and signal frequency are getting higher and higher with the development of electronic technology, it is inevitable to bring electromagnetic interference, so the following principles should be followed in PCB design to control the electromagnetic interference of the circuit board within a certain range, meet the design requirements and standards, and improve the overall performance of the circuit.

1. Selection of circuit board

The primary task of PCB design is to properly select the size of the circuit board. If the size is too large, the impedance value of the circuit will increase and the anti-interference ability will decline due to the long connection between components; Too small size will lead to dense component layout, which is not conducive to heat dissipation, and the connection is too thin and dense, which is easy to cause crosstalk. Therefore, the circuit board with appropriate size shall be selected according to the required components of the system.

The circuit board is divided into single panel, double panel and multilayer board. The selection of the number of circuit board layers depends on the functions to be realized by the circuit, the noise index, the number of signals and network cables, etc. A reasonable number of layers can reduce the EMC problem of the circuit itself. The general selection principles are:

① When the signal frequency is medium low frequency, there are few components, and the wiring density is low or medium, single panel or double panel shall be selected;

② Multilayer boards are used for high wiring density, high integration and many PCB components;

③ For circuit boards with high signal frequency, high speed integrated circuits and dense components, select 4 layers or more. In the design of multilayer board, a single layer can be used as the power layer, signal layer and grounding layer. The area of the signal loop is reduced and the differential mode radiation is reduced. Therefore, the multilayer board can reduce the radiation of the circuit board and improve the anti-interference ability.

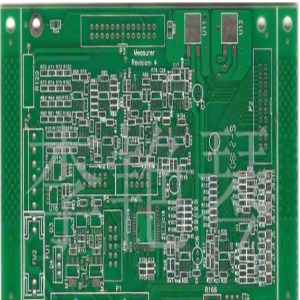

2. PCB layout of circuit board components

After the PCB size is determined, the position of special components shall be determined first, and then all components of the circuit shall be arranged in blocks according to the functional unit of the circuit. Digital circuit unit, analog circuit unit and power circuit unit shall be separated, and high-frequency circuit unit and low-frequency circuit unit shall also be separated. The layout principles of common circuit boards are as follows.

1) Principles for determining the location of special components:

① The heating element should be placed at a position conducive to heat dissipation, such as the edge of PCB, and away from the microprocessor chip;

② Special high-frequency components shall be placed close to each other to shorten the connection between them;

③ Sensitive elements shall be far away from noise sources such as clock generator and oscillator;

④ The layout of adjustable components such as potentiometers, adjustable inductors, variable capacitors and key switches shall meet the structural requirements of the whole machine for easy adjustment;

⑤ Heavy components shall be fixed with supports;

⑥ EMI filter shall be placed close to EMI source.

2) The principle of layout of umbrella components of the circuit according to the circuit functional unit:

① Each functional circuit shall be located according to the signal flow direction between them for wiring convenience;

② Each functional circuit shall first determine the position of core components, and place other components around the core components to minimize the wiring between components;

③ For high frequency circuit, the distribution parameters between components shall be considered;

④ Components placed on the edge of the circuit board shall be at least 2mm away from the edge of the circuit board;

⑤ DC/DC converter, switch tube and rectifier shall be placed as close to the transformer as possible to reduce external radiation;

⑥ The voltage regulating element and filter capacitor shall be placed close to the rectifier diode.

PCB design

3) Wiring principle between power supply and ground

Whether the power and ground wiring of PCB is reasonable is the key to reduce electromagnetic interference of the whole circuit board. The design of power line and ground wire is a problem that cannot be ignored in PCB, and it is often the most difficult design. The following principles should be followed in the design.

1) Wiring skills between power supply and ground

The wiring on PCB has the characteristics of impedance, capacitive reactance, inductive reactance and other distributed parameters. In order to reduce the influence of PCB wiring distribution parameters on high-speed electronic system, the wiring principles for power supply and ground are as follows:

① Increase the distance between wires to reduce the crosstalk of capacitive coupling;

② The power line and ground wire shall be laid in parallel to optimize the distributed capacitance;

③ According to the size of the carrying current, the width of the power line and ground wire should be thickened as much as possible to reduce the loop resistance. At the same time, the direction of the power line and ground wire in each functional circuit should be consistent with the direction of the signal transmission, which helps to improve the anti-interference capability;

④ The power supply and ground shall be directly routed above each other to reduce the inductance and minimize the loop area, and the ground wire shall be routed below the power line as far as possible;

⑤ The thicker the ground wire, the better. Generally, the width of the ground wire is not less than 3mm;

⑥ The ground wire is formed into a closed loop to reduce the potential difference on the ground wire and improve the anti-interference capability;

⑦ In the wiring design of multilayer boards, one layer can be used as the "all ground plane", which can reduce the grounding impedance and play a shielding role at the same time.

2) Grounding skills of each functional circuit

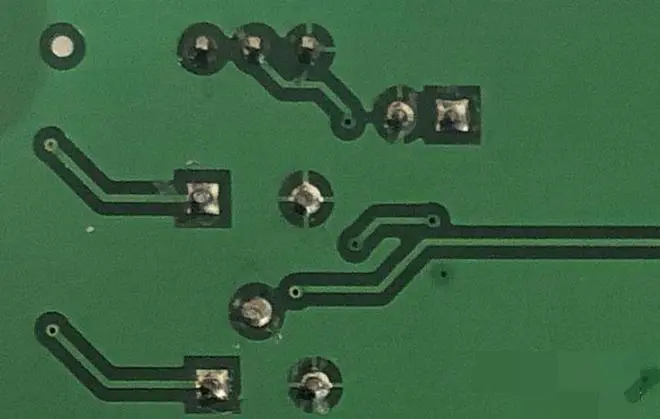

The grounding methods of each functional circuit of PCB are divided into single point grounding and multi-point grounding. Single point grounding can be divided into single point series grounding and single point parallel grounding according to the connection form. Single point series grounding is commonly used for protective grounding because of different lengths of grounding conductors, different grounding impedance of each circuit, and reduced EMC performance. Each circuit of single point parallel grounding has its own grounding wire, so the mutual interference is small, but the grounding wire may be extended and the grounding impedance may be increased, which is commonly used for signal grounding, analog grounding and power grounding. Multipoint grounding means that each circuit has a grounding point, as shown in Figure 5. Multipoint grounding is commonly used in high-frequency circuit, with short grounding wire and small grounding impedance value to reduce the interference of high-frequency signal.

In order to reduce the interference caused by grounding, grounding shall also meet certain requirements:

① The grounding wire should be as short as possible and the grounding ground should be large;

② Avoid unnecessary grounding circuit and reduce interference voltage of public grounding;

③ The grounding principle is to adopt different grounding methods for different signals, and all grounding points cannot be the same;

④ When designing multilayer PCB, the power supply layer and grounding layer should be placed in adjacent layers as far as possible, so as to form capacitance between layers in the circuit and reduce electromagnetic interference;

⑤ Try to avoid strong and weak current signals, and digital and analog signals sharing the ground.

24 Tips for Reducing Noise and Electromagnetic Interference

(1) If you can use low-speed chips, you don't need high-speed ones. High speed chips are used in key places.

(2) A series of resistors can be used to reduce the jumping rate of the upper and lower edges of the control circuit.

(3) Try to provide some form of damping for relays, etc.

(4) Use the clock with the lowest frequency meeting the system requirements.

(5) The clock generator shall be as close as possible to the device using the clock. The shell of quartz crystal oscillator shall be grounded.

(6) Circle the clock area with a ground wire and keep the clock wire as short as possible.

(7) The I/O drive circuit shall be as close to the edge of the PCB as possible, so that it can leave the PCB as soon as possible. The signal entering the PCB shall be filtered, and the signal coming from the high noise area shall also be filtered. At the same time, the serial terminal resistance shall be used to reduce the signal reflection.

(8) The useless end of MCD shall be connected high, or grounded, or defined as an output end. The power supply and ground terminals on the integrated circuit shall be connected, and shall not be suspended.

(9) The unused gate circuit input terminal shall not be suspended, the unused op amp positive input terminal shall be grounded, and the negative input terminal shall be connected to the output terminal.

(10) As far as possible, use 45 fold lines instead of 90 fold lines to reduce the external transmission and coupling of high-frequency signals.

(11) The printed circuit board shall be partitioned according to the frequency and current switching characteristics, and the noise components shall be further away from the non noise components.

(12) Single point power supply and single point grounding, power line and ground wire shall be as thick as possible for single panel and double panel. If the economy is affordable, multi-layer boards shall be used to reduce the inductance of power supply and ground.

(13) The clock, bus and chip selection signals shall be far away from I/O lines and connectors.

(14) Analog voltage input line and reference voltage terminal shall be far away from digital circuit signal line, especially clock.

(15) For A/D devices, the digital part and the analog part should be unified rather than crossed.

(16) The clock line perpendicular to the I/O line has less interference than the parallel I/O line, and the clock element pin is far away from the I/O cable.

(17) The component pin shall be as short as possible, and the decoupling capacitor pin shall be as short as possible.

(18) The key lines should be as thick as possible, and protective areas should be added on both sides. High speed lines should be short and straight.

(19) The lines sensitive to noise shall not be parallel to the high current and high-speed switching lines.

(20) Do not run wires under quartz crystal or noise sensitive devices.

(21) Do not form current loop around weak signal circuit and low-frequency circuit.

(22) The signal shall not form a loop. If it is unavoidable, the loop area shall be as small as possible.

(23) Each integrated PCB circuit has a decoupling capacitor. A small high-frequency bypass capacitor shall be added beside each electrolytic capacitor.

(24) Use high-capacity tantalum capacitors or Juku capacitors instead of electrolytic capacitors as circuit charging and discharging energy storage capacitors. When using tubular capacitors, the enclosure should be grounded.