1、 Electrical test

In the production process, it is inevitable that electrical defects such as short circuit, open circuit and electric leakage are caused by external factors. In addition to the continuous evolution of PCB towards high density, fine spacing and multi-level, if the defective boards are not screened out in time and allowed to flow into the process, it will inevitably cause more cost waste. Therefore, in addition to the improvement of process control, The technology of improving testing can also provide PCB manufacturers with solutions to reduce scrap rate and improve product yield.

In the production process of PCB products, the cost loss caused by defects varies in different stages. The earlier the defects are found, the lower the cost of remediation. "The Rule of 10's" is often used to evaluate the cost of repairing PCB defects found in different manufacturing stages. For example, after the blank board is made, if the open circuit in the board can be detected in real time, it is usually only necessary to repair the wire to improve the defect, or at most one blank board will be lost; However, if the circuit breaker is not detected, after the board is shipped to the downstream assembly company to complete the installation of the parts, the tin and IR are also remelted. However, at this time, the circuit breaker is detected. Generally, the downstream assembly company will demand compensation from the blank board manufacturing company for the part cost, rework cost, inspection cost, etc. If, unfortunately, the defective board is not found in the test of the assembler, but enters the finished products of the overall system, such as computers, mobile phones, auto parts, etc., then the loss found in the test will be a hundred times, a thousand times, or even higher than the loss found in the timely detection of empty boards. Therefore, for PCB manufacturers, electrical testing is to find the boards with circuit functional defects as early as possible.

Downstream operators usually require PCB manufacturers to conduct 100% electrical test, so they will reach an agreement with PCB manufacturers on test conditions and test methods. Therefore, both parties will clearly define the following items first:

1. Source and format of test data

2. Test conditions, such as voltage, current, insulation and continuity

3. Equipment manufacturing method and point selection

4. Test chapter

5. Repair specification

In the manufacturing process of PCB, there are three stages that must be tested:

1. After inner layer etching

2. After etching of outer circuit

3. Finished products

At each stage, there are usually 2 to 3 times of 100% testing, and the defective boards are screened out and then reworked. Therefore, the test station is also the best data collection source for analyzing the problem points in the manufacturing process. Through the statistical results, the percentage of open circuit, short circuit and other insulation problems can be obtained. After rework, the test can be carried out again. After sorting out the data, the root cause of the problem can be found and solved by using the quality control method.

PCB proofing

2、 Method and equipment of electrical measurement

The electrical testing methods include: Dedicated, Universal Grid, FlyingProbe, E-Beam, conductive cloth (glue), Capacity and ATG-SCANMAN. There are three types of equipment most commonly used, namely, dedicated testing machine, universal testing machine and flying probe testing machine. In order to better understand the functions of various devices, the following will compare the characteristics of the three main devices.

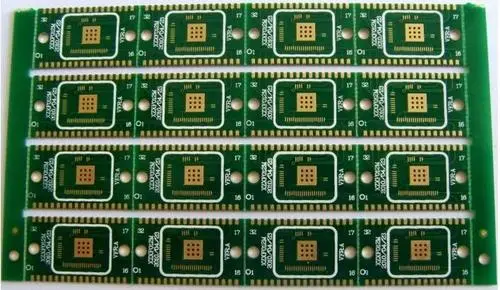

1. Dedicated test

The reason why the special type test is special is that the fixture (such as the needle disk used for electrical test on the circuit board) is only applicable to one type of material number, and boards with different material numbers cannot be tested and recycled. In terms of test points, the single panel can be tested within 10240 points and 8192 points on both sides. In terms of test density, due to the thickness of the probe head, it is more suitable for boards above pitch.

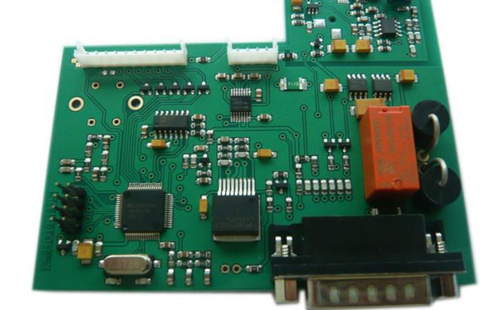

2. Universal Grid test

The basic principle of universal testing is that the PCB circuit layout is designed according to the grid. Generally, the so-called circuit density refers to the distance of the grid, which is expressed in pitch (sometimes it can also be expressed in hole density). The universal testing is based on this principle. According to the hole position, a G10 base material is used as the mask. Only the probe at the hole position can pass through the mask for electrical testing, so the fixture is easy and fast to make, And the probe can be reused. The universal test has a standard grid fixed large needle disk with many measuring points. The needle disk of the movable probe can be made according to different material numbers. As long as the movable needle disk is changed during mass production, the mass production test of different material numbers can be carried out.

In addition, in order to ensure the smooth circuit system of the completed PCB board, it is necessary to open/short the electrical test of the board with a needle disc of a specific contact on a universal electrical testing machine using high-voltage (such as 250V) multiple measuring points. This universal testing machine is called an ATE (Automatic Testing Equipment).

The number of universal test points is usually more than 10000. The test with a test density of or is called an on grid test. If it is applied to high-density boards, because the spacing is too dense, it has been separated from the on grid design. Therefore, it belongs to off grid test, and its fixtures must be specially designed. Generally, the test density of universal test can reach QFP.

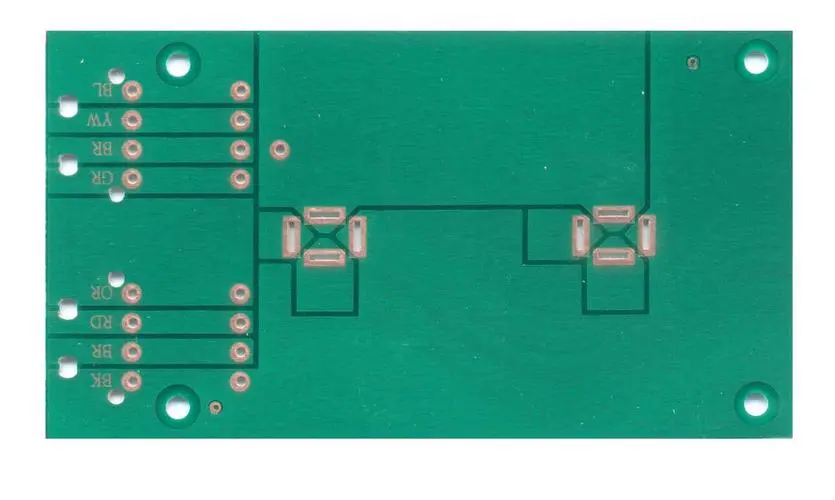

3. FlyingProbe test

The principle of flying probe test is very simple. It only requires two probes to move x, y and z to test two endpoints of each PCB circuit one by one, so it does not need to make expensive jigs. However, due to the endpoint testing, the testing speed is extremely slow, about 10-40 points/sec, so it is more suitable for samples and small volume production; In terms of testing density, the flying probe test can be applied to extremely high density boards.