Comprehensively understand the structure of solder paste printer and solder paste printer

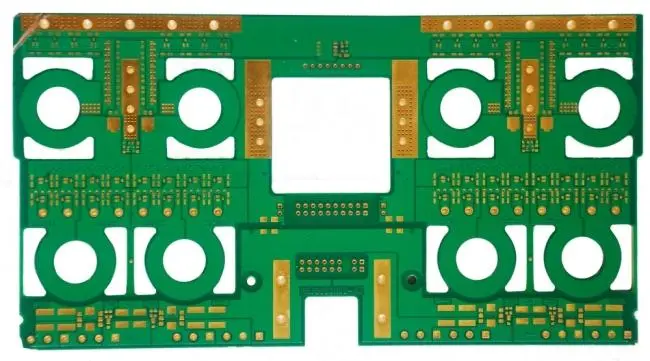

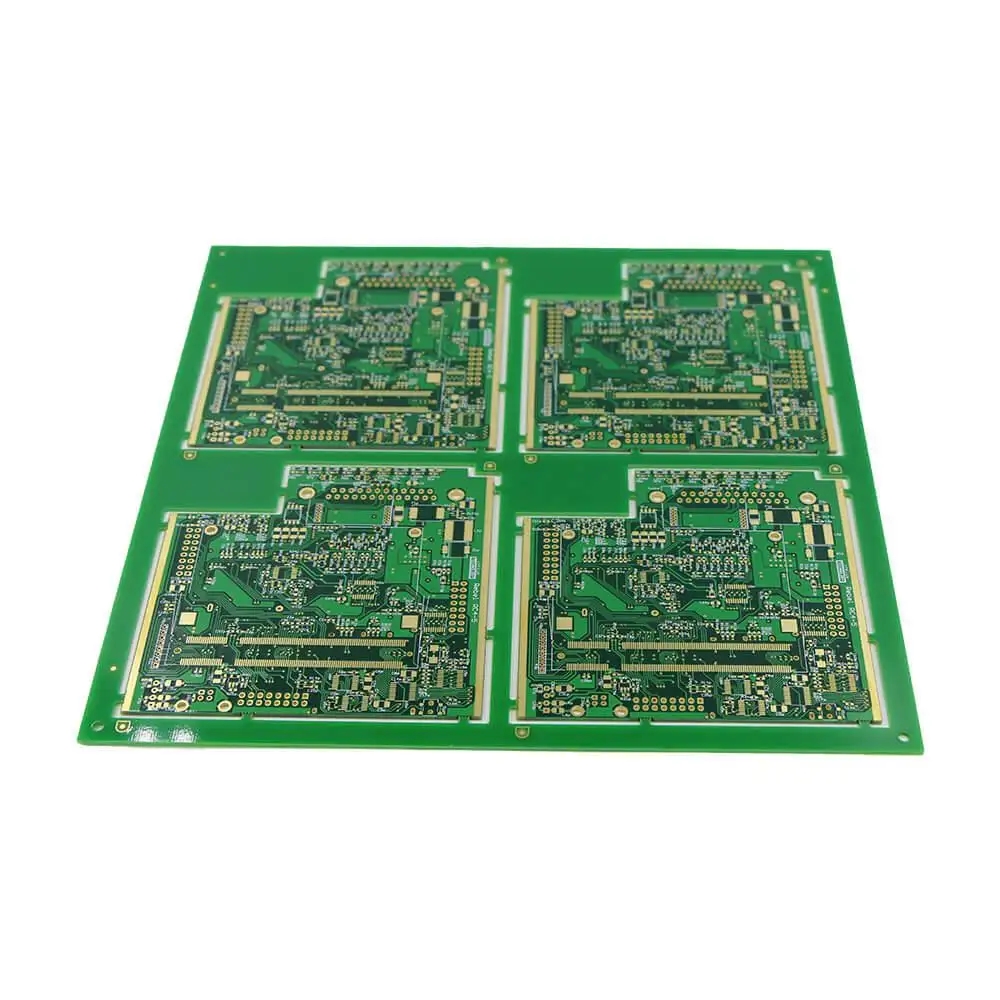

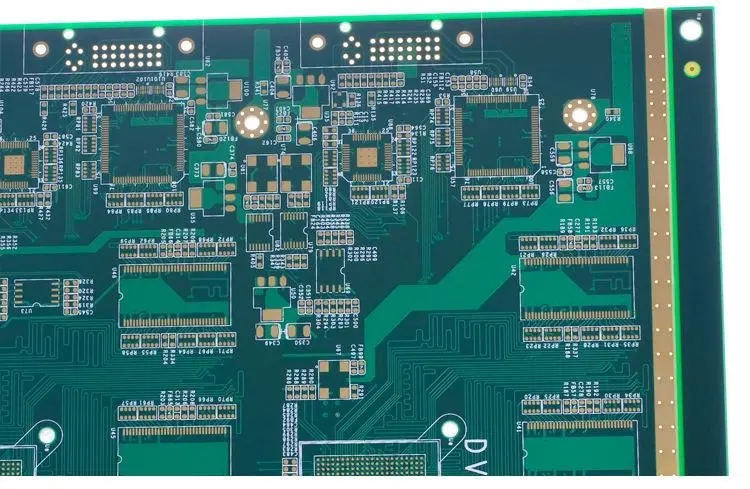

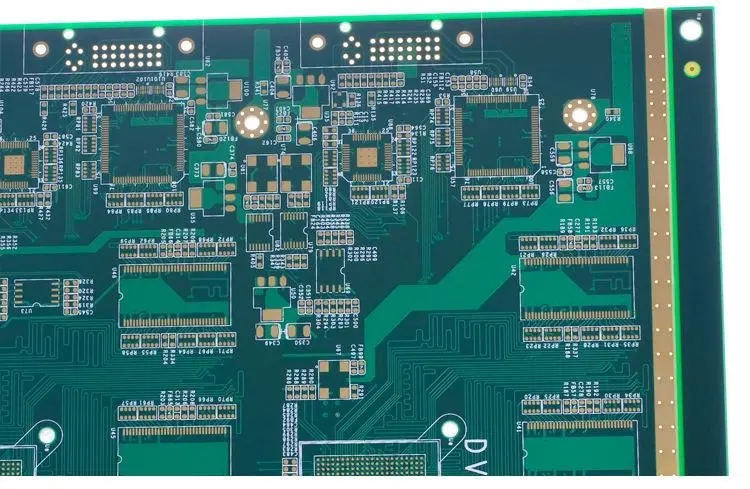

Solder paste printing machine is the main equipment that constitutes the SMT production line and the key equipment that affects the assembly quality. It is located at the front end of the SMT production line. Its function is to coat solder paste (paste solder) on the bonding pad of PCB without components and parts, so as to prepare for the welding of components and parts. Solder paste printing is considered as the key process step in surface mount technology to control the final solder node quality. Solder paste printing machines are manual, semi-automatic, full-automatic and other types. Solder paste printing machines configured in SMT production lines are generally full-automatic printing machines.

The basic function of the solder paste printer is to apply a certain amount of solder paste to each designated position of the PCB accurately, evenly and quickly using screen printing or screen printing technology. Full automatic solder paste printing machine can automatically complete a series of solder paste printing operations.

The main functional components of the solder paste printer include PCB transmission guide rail, printing (work) table, camera, solder paste filling, scraper device, computer control, power drive and other devices and systems.

The key to the success of solder paste printing is solder paste rolling, filling and demoulding. When the solder paste printer is running, the PCB is fed into the printing paste machine along the transmission guide rail. The base plate clamping device on the printing workbench clamps and locates the PCB edge, and fine adjusts the template for image alignment, so that the PCB's bonding pad pattern and the template's leak pattern are completely coincident. When the scraper moves forward at a certain speed and angle, a certain pressure is generated on the solder paste, which pushes the solder paste to roll in front of the scraper to generate the pressure to inject the solder paste into the template opening, so that the solder paste can smoothly fill the template opening.

When the printing is completed and the scraper leaves the template, it is demoulded. The integrity of demoulding determines the amount of solder paste missing and the integrity of solder paste graphics to achieve excellent printing performance.

Solder paste printing machine is the main equipment that constitutes the SMT production line and the key equipment that affects the assembly quality. It is located at the front end of the SMT production line. Its function is to coat solder paste (paste solder) on the bonding pad of PCB without components and parts, so as to prepare for the welding of components and parts. Solder paste printing is considered as the key process step in surface mount technology to control the final solder node quality. Solder paste printing machines are manual, semi-automatic, full-automatic and other types. Solder paste printing machines configured in SMT production lines are generally full-automatic printing machines.

① Adopting the most advanced, simple and reliable printing technology, it is a high-precision screen printing machine suitable for miniaturized, multi variety QFP, SOP, BGA, CSP, 0603 and other fine pitch electronic components.

② High precision and high rigidity body integrated structure ensures long-term stable printing performance. The position coordinates are set by the image processing device to ensure that the position error of the base plate and the template is within ± 0.015mm of high accuracy.

③ The printing table is operated interactively, and the door scraper moving mechanism with high rigidity and precision is used to ensure the parallelism of the printing table and the scraper, and ensure the uniformity of the printing paste within the printing range.

④ The pressure control of low friction cylinder can move smoothly along the concave and convex surfaces of the substrate to achieve stable printing.

⑤ It is featured by simple and convenient operation, multi-function, high-quality and stable fine pitch printing. The utility model has an effective roll paper cleaning function, which saves the inconvenience of manually cleaning the steel mesh.

PCB manufacturers, PCB designers and PCBA processors will give you a comprehensive understanding of the structure of solder paste printers and solder paste printers.