Analysis and Design of PCB Power Supply System

Today, if the design of high-speed motor PCB board does not thoroughly grasp the characteristics of the chip power system, the electronic system will be difficult to succeed In fact, in order to meet the requirements of lower power supply voltage, faster signal inversion speed, higher integration, and more and more challenging requirements, many companies at the forefront of electronic design ensure power supply during product design And signal integrity, a lot of money, labor, and investment in power supply system analysis This analysis and design of power supply systems (PDS) is coming more and more important in the field of high speed circuit design, especially in the computer field, transistor, communication, network, and consumer electronics industry With the inevitable further expansion of VLSI technology, the supply voltage of integrated circuits will continue to decrease As more and more manufacturers switch from 130nm technology to 90nm technology, it can be predicted that the power supply voltage will drop to 1.2V or even lower, and the current will also increase significantly From DC infrared voltage drop to AC dynamic voltage fluctuation control, because the allowable noise range is getting smaller and smaller, this development trend brings great challenges to the design of power supply system

PCB board

Overview of PCB board power system design

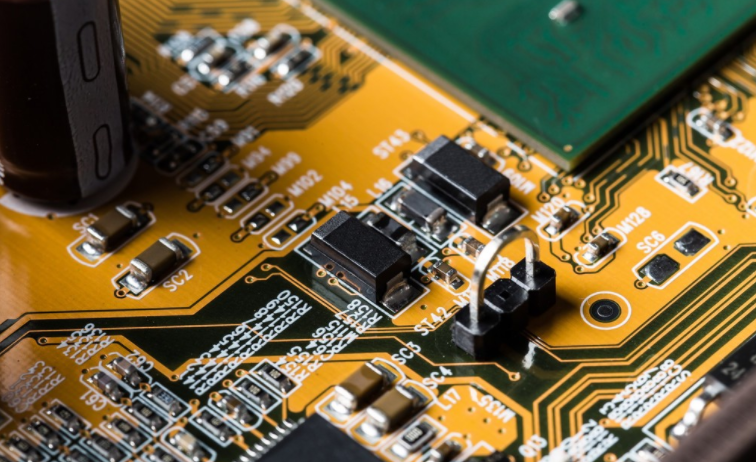

In AC analysis, the input impedance between power supply and ground is an important observation value for measuring the characteristics of power supply system. The determination of this observation evolved into the calculation of IR drop in DC analysis. Whether in DC or AC analysis, the factors that affect the characteristics of the power supply system are: the layer of PCB, the shape of the power board layer, the layout of components, and the distribution of vias and pins. The concept of input impedance between power supply and ground can be used for simulation and analysis of the above factors. For example, a very wide application of power supply input impedance to ground is to evaluate the placement of coupling capacitors on the board. Placing a certain number of decoupling capacitors on the circuit board can suppress the unique resonance of the circuit board itself, thus reducing the generation of noise, and also can reduce the edge radiation of the circuit board to alleviate the electromagnetic compatibility problem. In order to improve the reliability of the power supply system and reduce the manufacturing cost of the system, system design engineers must often consider how to economically and efficiently select the system layout of decoupling capacitors. The power system in high-speed circuit system can generally be divided into three physical subsystems: chip, integrated circuit package structure and PCB board. The power grid on the chip consists of several metal layers placed alternately. Each metal layer is composed of metal strips in X or Y direction to form a power supply or grounding grid, and the metal strips in different layers are connected through holes. For some high-performance chips, many decoupling units are integrated into the power supply of the core or IO. The integrated circuit package structure is similar to a simplified PCB board, and has multiple layers of power or ground planes with complex shapes. On the upper surface of the package structure, there is usually a mounting position for the decoupling capacitor. PCB board usually contains a continuous large area power supply and ground plane, as well as some discrete decoupling capacitor components and a power rectifier module (VRM). The bonding wire, C4 bump and solder ball connect the wafer, package and PCB together. The entire power supply system must ensure that each integrated circuit device is provided with a stable voltage within the normal range. However, switching currents and parasitic high-frequency effects in these power systems always introduce voltage noise. The voltage change can be calculated: Î V is the voltage fluctuation observed on the equipment, and Î I is the switching current. Z is the input impedance between the power supply and ground of the whole power supply system observed on the equipment. To reduce voltage fluctuations, keep the resistance between the power supply and the ground low. In DC case, since Z becomes a pure resistance, low resistance corresponds to low power supply voltage drop. In AC case, low resistance also reduces the transient noise generated by switching current. Of course, this requires that Z be kept small in the broadband. Please note that the power supply and grounding are usually used as signal loops and reference planes. There is a close relationship between the power supply system and the signal distribution system. However, due to space limitations, this paper will not discuss the noise phenomenon and current loop control in power systems introduced by synchronous switching noise (IO SSO). The following sections will ignore the signal system and only focus on the analysis of the power system.

DC IR voltage drop

Because the characteristic size of the chip grid is very small (several microns or even smaller), and the resistance loss in the chip is serious, the infrared voltage drop in this chip has been widely studied. In the following cases, the IR voltage drop on the PCB (in the range of tens to hundreds of millivolts) will also have a greater impact on the high-speed system design. On the power board layer, due to the Swiss Chess structure, Neck Down structure and dynamic cabling, the board plane is divided (Figure 1); The number of device pins, through-hole, solder ball and C4 bump power boards where current passes through the power board layer is insufficient, the thickness of the power board is insufficient, and the current path is unbalanced.; The system design requires low voltage, high current and more strict voltage floating range. For example, devices with high density and high pin count usually form the so-called Swiss chess structure effect on the chip packaging structure and the PCB distribution layer due to a large number of vias and reverse pads. Swiss chess structures produce many tiny metal regions with high resistance. Depending on the power supply system, there is a high resistance current path, and the current voltage sent to the components on the PCB may be lower than the design requirements. Therefore, a good DC IR voltage drop analogy is the key to estimate the allowable voltage drop range of the power system. Provide design solutions or rules for pre, post placement and routing by analyzing various possibilities. The layout engineer, system engineer, signal integrity engineer and power supply design engineer can also include IR voltage drop analysis in the constraint manager as the last step to perform design rule check on each power supply and grounding grid on the PCB. Inspection tool (DRC). The design process of automated software analysis can avoid the layout and wiring problems of complex power system structures, which cannot be found through visual inspection or even experience. Figure 2 shows that IR voltage drop analysis can accurately determine the distribution of critical voltage and current in the power supply system on high-performance PCB.

Analysis of grounding impedance of AC power supply

Many people know that a pair of metal plates form a plate capacitor. They think that the feature of the power plate layer is to provide plate capacitors to ensure the stability of the power supply voltage. When the frequency is low and the signal wavelength is much larger than the panel size, the power board layer and the floor do form capacitors. However, when the frequency is increased, the characteristics of the power plane layer begin to become complex. More precisely, a pair of flat plates constitute a flat plate transmission line system. The noise or corresponding electromagnetic field between the power supply and the ground propagates between circuit boards according to the transmission line principle. When the noise signal propagates to the edge of the panel, part of the high-frequency energy is radiated, but the larger part is reflected back. Multiple reflections from different edges of the board constitute a resonance phenomenon in PCB. In AC analysis, the impedance resonance of PCB power supply to ground is a unique phenomenon. For comparison, the impedance characteristics of pure capacitors and pure inductors are also plotted. The size of the board is 30cm 20cm, the plate spacing is 100um, and the filling medium is FR4 data. The power rectifier module on the board is replaced with a 3nH inductor. It is a 20nF capacitor with pure capacitance impedance characteristics. It can be seen from the figure that when there is no power rectifier module on the board, the impedance characteristic (red line) of the board is the same as the capacitance (blue line) within the frequency range of tens of megabytes. Above 100MHz, the impedance characteristic of the board is inductive (along the green line). After reaching the frequency range of several hundred megabytes, several resonance peaks appear to show the resonance characteristics of the plate, and the plate is no longer purely inductive. So far, it is clear that low resistance power supply system (from DC to AC) is the key to obtain low voltage fluctuation: reducing inductance effect, adding capacitance effect, and eliminating or reducing these resonant peaks are design goals.

In order to reduce the impedance of the power supply system, some design guidelines should be followed:

1) Reduce the distance between the power supply and the floor;

2) Dimensions of new boards;

3) Increase the dielectric constant of the filled medium;

4) Use multiple pairs of power layers and floor layers.

However, due to manufacturing or other design considerations, design engineers also need to use more flexible and effective methods to change the impedance of the power supply system. In order to reduce the impedance and eliminate these resonant peaks, it has become a common method to place discrete decoupling capacitors on PCB.

The input impedance of the power system is calculated using Sigrity PowerSI:

a. There is no power rectifier module and no decoupling capacitor is placed on the board.

b. The power rectifier module is analogized by short circuit, and no decoupling capacitor is placed on the board.

c. Perform short circuit analogy for power rectifier modules, and place decoupling capacitors on the board.

Discrete decoupling capacitors are placed on the circuit board to enable designers to flexibly adjust the impedance of the power supply system to achieve low power to ground noise However, how to choose the placement position, how many to choose, and which decoupling capacitor to choose are still a series of design problems Therefore, it is usually necessary to find a decoupling solution for a specific design, and use appropriate design software to extensively simulate PCB boards for power systems