FR-4

Material, which is the abbreviation of glass fiber cloth, is a kind of raw material and base material of circuit board, and the code of fire resistant material grade, which means that the resin material must be able to extinguish itself after burning. It is most commonly used in PCB (printed circuit board). Generally, single, double and double sides are made with this! Because of its high strength and flame retardancy, most circuit boards will choose FR-4 as the base material.

FR-4

2. What is PCB and its composition?

PCB is the abbreviation of Printed Circuit Board in English. Its Chinese name is printed circuit board, also known as printed circuit board and printed circuit board, and it is an important electronic component. It is the supplier of electrical connection of electronic components.

PCB starts from the most basic unit: substrate, which is composed of several layers, and each layer plays an important role in the function of the final PCB. These alternate layers include:

• Base material: This is the basic material of PCB. It makes the PCB rigid.

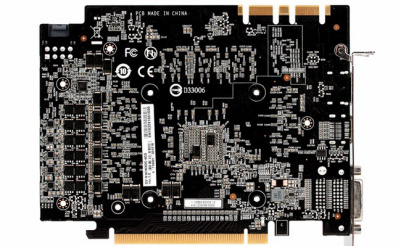

• Copper: Add a thin conductive copper foil on each functional surface of the PCB - on one side if it is a single-sided PCB, and on both sides if it is a double-sided PCB. This is the copper wiring layer.

• Solder resistance layer: the top of the copper layer is a solder resistance layer, which gives each PCB a unique green color. It makes the copper trace unintentionally contact with other conductive materials that may cause short circuit. In other words, solder keeps everything in place. The holes in the solder mask are the places where the PCB components are connected to the circuit board with solder. The solder mask is a key step in the smooth manufacturing of PCBA, because it can prevent welding on unnecessary parts and avoid short circuit.

• Silk screen: white silk screen is the last layer on PCB. This layer adds labels on the PCB in the form of characters and symbols. This helps with the functionality of each component on the dashboard.

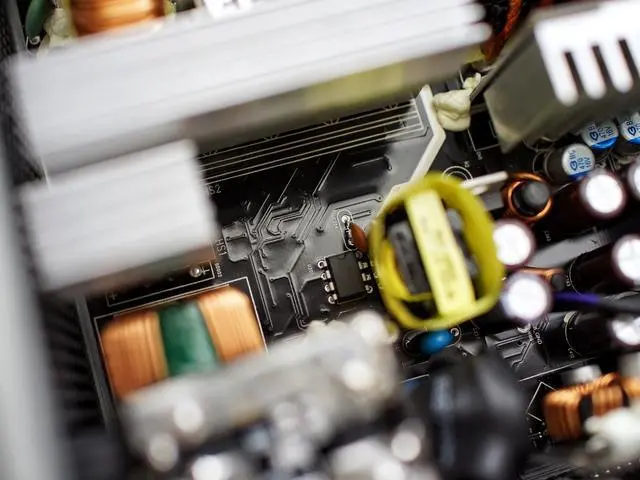

PCB varies according to its substrate materials, including high-frequency microwave plate, metal substrate, aluminum substrate, iron substrate, copper substrate, double-sided plate and multilayer plate. Its circuit is used as a tool for conducting between components. In design, large copper surface will be additionally designed as the grounding and power supply layer. Lines and drawings are made at the same time. The wiring density is high, the volume is small, and the weight is light, which is conducive to the miniaturization of electronic equipment.

The base plate of the board itself is made of insulating and heat-insulating materials that are not easy to bend. On the surface, it can be seen that the small circuit material of PCB is copper foil. Originally, the copper foil was covered on the whole board, but part of it was etched during the manufacturing process, and the remaining part became a mesh of small circuit.

3. Advantages and characteristics of FR-4

General single, double and multilayer PCB boards are made of FR-4. FR in FR-4 represents flame retardant, while the number 4 distinguishes this material from other materials in this category. FR-4 is a glass fiber reinforced epoxy laminate, which looks like a thin woven cloth board. The term FR-4 also represents the grade used to manufacture these laminates. Glass fiber structure provides structural stability for materials. The glass fiber layer is covered with flame retardant epoxy resin. This brings durability and strong mechanical properties to the material. All these features make FR-4 PCB very popular among electronic contract manufacturers.

Its technical features mainly lie in: electrical insulation, stability, good flatness, smooth surface, no pits, and thickness tolerance standard, which are suitable for products with high-performance electronic insulation requirements, such as FPC reinforcement plate, PCB drilling pad, glass fiber meson, potentiometer carbon film printed glass fiber plate, precision planetary gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation brace partition, insulation pad Transformer insulation plate, motor insulation parts, grinding gear, electronic switch insulation plate, etc.

FR-4 sheet is now widely used in military, communications, computers, digital circuits, industrial instruments, automotive circuits and other electronic products. All performance indicators can meet the needs of general industrial electronic products. Very good price performance ratio.

![7 factors affecting the price of PCB board [Detailed explanation]](https://www.kingfordpcb.com/uploadfile/ueditor/image/202211/16672906057a0677.jpg)