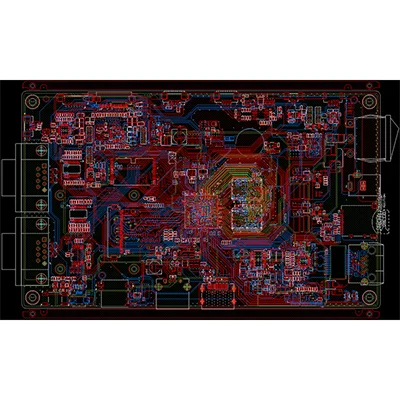

10-layer second-order HDI PCBA design

Name: 10-layer second-order HDI PCBA design

Plate: TG170 /TG180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

HDI PCB (2+N+2): This is a moderately complex HDI PCB layout design structure that contains 2 or more high-density interconnect layers, allowing conductors and copper free interconnects on any layer of the PCB to fill the stack Microporous structure. These structures are commonly found in challenging designs that require a high level of signal transmission performance. They are suitable for BGAs with smaller ball pitches and higher I/O counts and can be used to increase routing density in complex designs while maintaining thin finished board thicknesses.

Name: 10-layer second-order HDI PCBA design

Plate: TG170 /TG180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL