The success or failure of ink use directly affects the overall technical requirements and quality indicators of PCB shipment. Therefore, they attach great importance to the performance of ink. In addition to ink viscosity is widely known, as the thixotropy of ink is often ignored. However, it plays an important role in screen printing. In order to more clearly explain the impact of thixotropy on screen printing effect, we must also start from the most basic principles of ink and screen printing. Then the concept of thixotropy is introduced.

In the whole production process of modern PCB, ink has become one of the indispensable auxiliary materials in PCB manufacturing process. It occupies a very important position in PCB process materials. The success or failure of ink use directly affects the overall technical requirements and quality indicators of PCB shipment. Therefore, PCB manufacturers attach great importance to the performance of ink. In addition to ink viscosity is widely known, as the thixotropy of ink is often ignored. However, it plays an important role in screen printing.

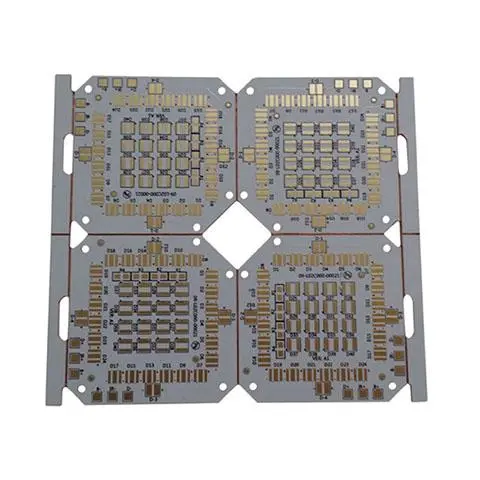

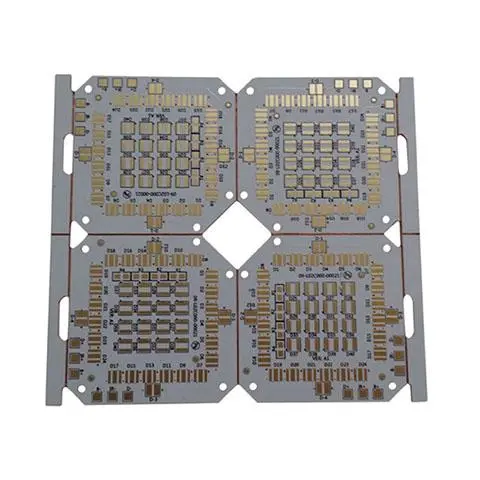

PCB board making

In order to more clearly explain the impact of thixotropy on screen printing effect, we must also start from the most basic principles of ink and screen printing. Then the concept of thixotropy is introduced. Next, we will analyze and explore the influence of thixotropy on ink performance in PCB manufacturing:

1、 Wire mesh

Screen printing process is one of the indispensable materials. Without screen, it cannot be called screen printing. Screen printing is the soul of screen printing technology. The silk screen is almost all silk fabrics (of course, there are also non silk fabrics)

Generally, nylon, polyester and stainless steel are distinguished by materials

It can be divided into plain weaving and damask weaving by weaving method

According to the structure of silk, it can be divided into single strand and multi strand

According to the thickness of the mesh, it can be divided into: s (thin), t (medium), hd (heavy)

The mesh number can be roughly divided into: low mesh, medium mesh and high mesh

In the PCB industry, the most commonly used is the t-net. S and hd networks are generally not used except for some special needs. This is because the PCB industry is a highly professional industry with high technology, which is different from making simple manual and artistic skills. Generally, the technical level of manual and artistic skills is not high, as long as it can meet or achieve human visual effects. For PCB, it is not only good to look neat and beautiful. If PCB is used for current conduction and signal transmission, it must meet the precise geometric dimension required by electrical performance, which requires strict measurement. Therefore, we need to know several important technical parameters related to the screen.

① Thickness of wire mesh: The thickness refers to the measured value of the thickness of the wire mesh when it stands under no tension. The measured value is the statistical average value obtained from the measured data μ M means. The thickness is determined by the diameter of the wire forming the screen and is related to the ink penetration of the screen.

② Opening area ratio of wire mesh: it is the ratio of mesh area and wire mesh area, expressed as%. The larger this value is, the larger the opening of the mesh will be.

③ Ink penetration of screen: this refers to the theoretical value. In actual screen printing production, the ink penetration is affected by factors such as screen material, performance, specification, viscosity of ink, fineness of pigment, thixotropy of ink, hardness of scraper, printing pressure, printing speed, contact distance, etc

2、 Ink

It refers to colored colloidal substances used for printed boards. It is usually composed of synthetic resin, volatile solvent, oil and filler, desiccant, pigment and diluent. It is often called ink.

(1) Composition of ink:

1. Resin: Resin is an important component to form ink film and determine ink performance. Famous PCB ink brands have their own patented formulas. Usually we say how good the performance of this brand of ink is. In fact, it is the resin that plays a very important role in it. It determines the operability, glossiness, cohesiveness, hardness, water resistance, solvent resistance, acid and alkali resistance, temperature resistance, etc. of the ink.

2. Solvent:

Function of solvent:

① Dissolve the resin. Make it a good binding material;

② Dissolving pigments and additives;

③ Adjust the ink viscosity;

④ Adjust the drying speed of the ink;

⑤ The dissolution and penetration of the substrate can enhance the adhesion.

The solvent of the ink is not a single variety but a component. Considering the problems of solubility and drying speed, most solvents are mixed. Different inks, different uses, have different solvents. So ink manufacturers will be equipped with several different types of solvents. For one ink, only one or two types of solvents can be used. Generally speaking, for the same ink manufacturer, since the resin system used for research and development is basically determined, the solvent provided by the same ink manufacturer can be universal. For example, the printing ink produced by Coates in the UK can basically be used as long as it is the solvent produced by Coates in the UK. However, we still insist that an ink should be matched with a matching special thinner.

⑴ Diluent series products provided by coates

⑵ Coates products and corresponding diluents

If diluent is used at will, it will cause ink gel (caking), peeling, uneven color, chemical resistance, thermal shock resistance, adhesion and other undesirable problems. It is incorrect to add "white water proof" and "783" as a universal solvent to any ink.

3. Color material: mainly pigment. Pigments are classified into organic pigments and inorganic pigments. Organic pigments refer to non mineral pigments, which are colorful and have complete chromatograms, but usually have poor hiding power. Inorganic pigments refer to minerals. For example, titanium white, zinc white, iron blue, carbon black, etc., they have good hiding power, strong light resistance and aging resistance. PCB inks are mostly of this kind.

In addition to being used as pigment, pigment also plays a certain role in light resistance, heat resistance, flux resistance, chemical resistance and other aspects of ink.

4. Auxiliary agent: The purpose of adding auxiliary agent in the ink is to improve the physical performance of the ink, enhance the printability of the ink, and improve the printing effect. Auxiliary agents include defoamer, dispersant, diluent, homogenizer, firming agent, color separation inhibitor, precipitation inhibitor, plasticizer, coupling agent, ultraviolet absorber, catalyst, thickener, etc.

3、 Several Important Technical Properties of PCB Ink

In principle, it is impossible to separate PCB ink from the combination of the above components if it is of excellent quality. Excellent ink quality is the comprehensive embodiment of scientific formula, progressiveness and environmental protection. It is reflected in:

(1) Viscosity: short for dynamic viscosity. It is generally expressed in viscosity, that is, the shear stress of fluid flow divided by the velocity gradient in the direction of the flow layer, in Pa. s or mpa. s. In PCB production, it refers to the fluidity of ink caused by external forces.

(2) Plasticity: refers to the property of printing ink that remains unchanged after deformation due to external force. The plasticity of ink is helpful to improve printing precision;

(3) Thixotropy: (thixotropic) A property in which the ink is colloidal when it is stationary, and the viscosity changes when it is touched, also known as shake and sagging resistance;

(4) Liquidity: (leveling) The extent to which the ink spreads out under the action of external force. The fluidity is the reciprocal of viscosity, which is related to the plasticity and thixotropy of ink. The greater the plasticity and thixotropy, the greater the fluidity; If the liquidity is high, the impression is easy to expand. Those with low mobility are prone to netting and inking, also known as reticulation;

(5) Viscoelasticity: refers to the ability of the ink to rebound quickly after being sheared and broken by the scraper. It is required that the ink deformation speed is fast, and the ink rebounds quickly to facilitate printing;

(6) Dryness: it is required that the slower the ink dries on the screen, the better, and the faster the ink is transferred to the substrate, the better;

(7) Fineness: particle size of pigment and solid material, PCB ink is generally less than 10 μ m. The fineness shall be less than one-third of the mesh opening;

(8) Drawing property: When the ink is lifted with an ink shovel, the extent to which the filiform ink does not break is called drawing property. The ink filament is long, and there are many filaments on the ink surface and printing surface, making the substrate and printing plate dirty, or even unable to print;

(9) Transparency and hiding power of printing ink: For PCB printing ink, various requirements for transparency and hiding power of printing ink are put forward according to different purposes and requirements. Generally speaking, line ink, conductive ink and character ink should have high hiding power. The solder resist is more flexible.

(10) Chemical resistance of printing ink: PCB printing ink has strict standards for acid, alkali, salt and solvent according to different purposes.

In practical applications, the greater the thixotropy, the better, and the smaller the thixotropy, the better. It is just enough. Because of its thixotropic property, ink is very suitable for screen printing. The screen printing operation becomes easy and free. When printing ink, the ink on the screen is pushed by the squeegee to roll and squeeze, and the viscosity of the ink becomes lower, which is conducive to ink penetration. After the ink is screen printed on the PCB substrate, due to the viscosity is not recovered quickly, there is an appropriate leveling space to allow the ink to flow slowly. When the recovery balance is reached, the edges of the screen printed graphics will get satisfactory flatness.