1 Introduction

With the development of science and technology and the rapid improvement of industrial technology, we often need to accurately measure and control the ambient temperature and equipment temperature in our daily life and production. Therefore, it is very important to study the measurement and control of temperature.

We need to sense the temperature from the outside world, and the key is the temperature sensor, which is completed here with LM35. After obtaining the temperature value of the outside world, certain display devices are needed to display it. The current popular method is to convert analog to digital through A/D converter, which is done here with ICL7107. Then it is displayed by LED or LCD. The thermometer described below is displayed with a double positive digital tube (LED).

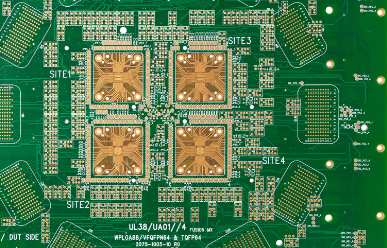

2. Draw the circuit diagram of digital display thermometer and PCB design method

We want to successfully design a thermometer PCB, roughly through the following steps: first learn to draw the schematic diagram of the thermometer. The first step is to set up a component library (Sch.Lib) to meet the design needs. When making components, we should put multiple components in a library for easy call. If necessary, the component is described in the library file. You can select the component in Browse Schlib Components, Then make corresponding Description in Description (Description, Footprint, default Designator, Sheet part Filename). When making components, we must pay attention to some minor problems, such as: when making symbols of TL431 components, the pins are not placed on the grid, the wires cannot be connected properly when tuning to the schematic diagram, and the nodes cannot exist on the pins. At this point, we can click the right mouse button in the production window to select Doument options, and set Snap and Visibie in Gird options in the library Editor Workespace dialog box that pops up.

There is also the art of building components such as copying similar components from an existing library into your own library and modifying them. When making integrated chips Icl7107, Icl7660 and S-DSP, we must pay attention to the attributes of each pin and carefully set them one by one, so as not to burn the chips during debugging due to wrong connection in the schematic diagram. In the second step, the components to be used are transferred to the schematic diagram for connection. In the connection process, attention should be paid to the connection of the bus. The bus is only a schematic electrical connection, and the real connection is the network label. Therefore, the network label must be placed when the bus is used. In the third step, after the circuit diagram is connected, we must perform ERC, Reports/Bill of material, and Create netlist operations. Electrical rule check to correct circuit errors in the circuit diagram. Conduct component report to view component information of circuit diagram. Create the network table in preparation for PCB drawing.

The second step to complete the PCB production. The first step of making a PCB, determining the physical size of the board frame, the size of the wiring and the various board layers required, can be completed through the wizard. In the second step, after defining the PCB, call the menu bar command Design/Load Nets to import the component into the PCB. When placing the component, it should be noted that different components need to be placed in different board layers, for example, the name (pinyin) should be placed in the BottomLayer, and the horizontal mirror image should not be used. The third step, select the jumper through the hole form. Step 4: Select the component form and the number of copper film lines passed between the welding pad, and call the menu bar command Design/Rules for setting. Step 4: Set cable parameters. The fifth step is to Check the design Rules after connecting the PCB. Call the menu bar command Tools/Designs Rules Check. This can be done to avoid design errors and electrical errors.

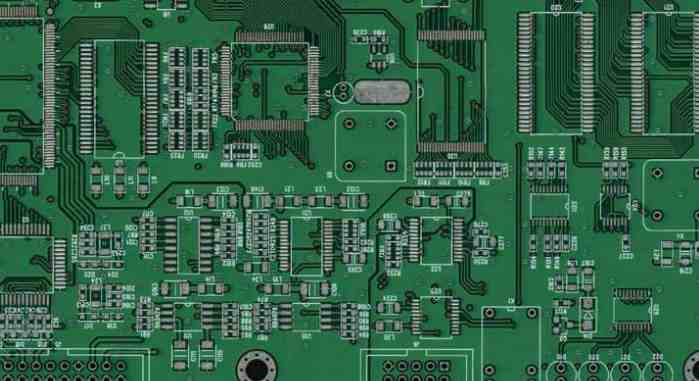

3. PCB drawing printing, transfer printing, corrosion processing and problems of copper-coated plate.

1. Print PCB drawings to thermal transfer paper with laser printer (make PCB with thermal transfer paper)

Add a printer in the Start menu

Follow the Add Printer wizard step by step (if no actual printer is connected, just choose one)

PCB Print Settings: The window switches to the PCB you want to print. Under File, select Print/Preview, and a PPC format document is displayed under Explorer: To Preview PCBPPC, switch the manager to Browse PCBPrint and select the layer you want to print. The Settings for the underlying print graphics are in the Layers bar and move the MultiLayer to the top layer

n Select Show Holes in the Options box

n Select Black & White in the Color Set column.

When designing the PCB, place "String" in the Bottom Layer, write your name (pinyin) and design date in it. Name and date should be mirrored horizontally. Once set up, print the underlying graphic onto heat transfer paper.