In circuit board surface treatment, there is a very common process called gold. The process of gold plating is to deposit the stable color, good brightness, smooth coating and good weldability nickel gold coating on the PCB printed circuit surface. PCB also has a golden color after sinking gold, which is closer to gold, because sinking gold is brighter and more beautiful than gilding. Next, Shenzhen PCB Board factory - kingford to introduce the four characteristics of PCB gold sinking process.

Four characteristics of PCB gold sinking process

1. The sunken gold plate has bright color, good color and beautiful appearance, which enhances its appeal to customers.

2. Compared with other surface treatments, the crystal structure formed by sinking gold is easier to weld and has better performance to ensure the quality.

3. Since there is only nickel and gold on the plating pad, the signal of skin effect is transmitted in the copper layer, so the signal will not be affected.

4. Because there is only nickel and gold on the gold plate welding plate, the welding resistance layer of the circuit is tightly combined with the copper layer, which is not easy to occur micro short circuit.

The flatness and atmospheric life of PCB gold plating plate is the same as that of gold plating plate, so now most factories use gold plating process to produce gold plating plate.

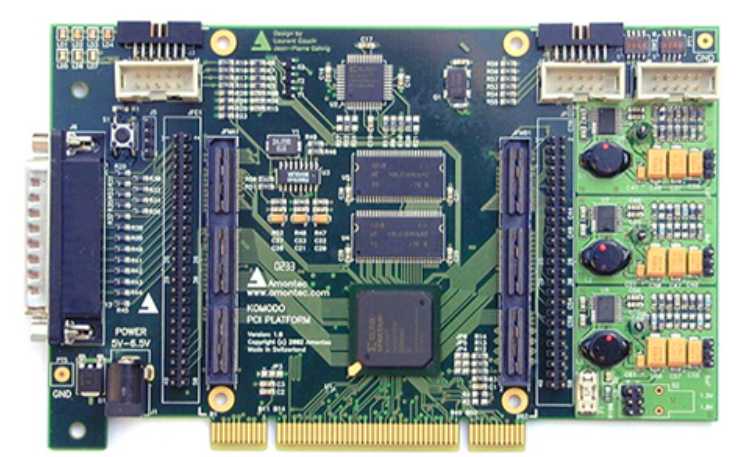

PCB board making ability

Energy production from 2 layers to 14 layers, 14-22 layers can be proofing production.

Minimum line width/spacing: 3mil/3milBGA Spacing :0.20MM

Minimum aperture: 0.1mm Size :610mmX1200mm

Ink: Tamura, Taiyo, Fudoken;

FR4: Shengyi, Kingboard, Harbour, Hongren, Guoji, Hezheng, Nanya,

(Shengyi S1130/S1141/S1170),Tg130℃/ Tg170℃ T g180℃ and other high TG plates)

High frequency plate: Rogers, Taconic, ARLLON;

Surface process: tin spray, lead-free tin spray, gold plating, full plate gold plating, plug gold plating, full plate thick gold, chemical tin (silver), anti-oxidation (OSP) blue glue, carbon oil

2. Performance and characteristics of PCB aluminum substrate

Aluminum substrate is widely used in the electronics industry and lighting industry, so why is aluminum substrate widely used? In fact, the main reason why aluminum substrate is widely used is determined by the characteristics and properties of aluminum substrate. Next, Shenzhen PCB Board factory -kingford will introduce the performance and characteristics of PCB aluminum substrate.

Shenzhen aluminum substrate manufacturer

Performance of aluminum PCB substrate

1. Stability: The stability of aluminum substrate is better, the main reason is that the size change of aluminum substrate is generally small, and it is more stable than the printing board made of all insulating materials on the market.

2. Insulation: aluminum substrate insulation performance is very good, hardness is also very high, can be a good substitute for fragile ceramic plate, so as to effectively reduce the real area required by the printing board, so that the product does not need to install the radiator, can improve the heat dissipation of the product, improve the efficiency of the product, reduce the cost.

3. Thermal expansibility. Aluminum substrate can improve the heat dissipation function of the product, so as to alleviate the thermal expansion and cold contraction of the components on the printing board, and improve the reliability of the product, so that the product is more durable.

The characteristics of PCB aluminum substrate

1. Aluminum substrate is a kind of low alloy alloy plate with high plasticity, which has good thermal conductivity, insulation and machinability. Used in the working circuit, it has a good effect on the heat dissipation of electrical appliances.

2. In the use of electrical products, can effectively reduce the operating temperature of electrical appliances, so as to effectively improve the working efficiency of electrical appliances, to a certain extent can extend the service life of electrical products.

3. Compared with ceramic substrate, aluminum substrate has higher hardness, is not easy to break, makes mechanical durability, small density and small volume, so it occupies a smaller position in the product.

We do board advantage: PCB capacity of 40000 square meters 40 high precision circuit board | | to do 1 - four domestic auto enterprises | military cooperation unit circuit board level supplier

kingford is a circuit board manufacturer specializing in the manufacture of printed circuit boards, specializing in the production of single, double-sided and multi-layer circuit boards. We can provide PCB proofing and mass production services such as FR4 hard board, FPC soft board, HDI board and metal substrate.