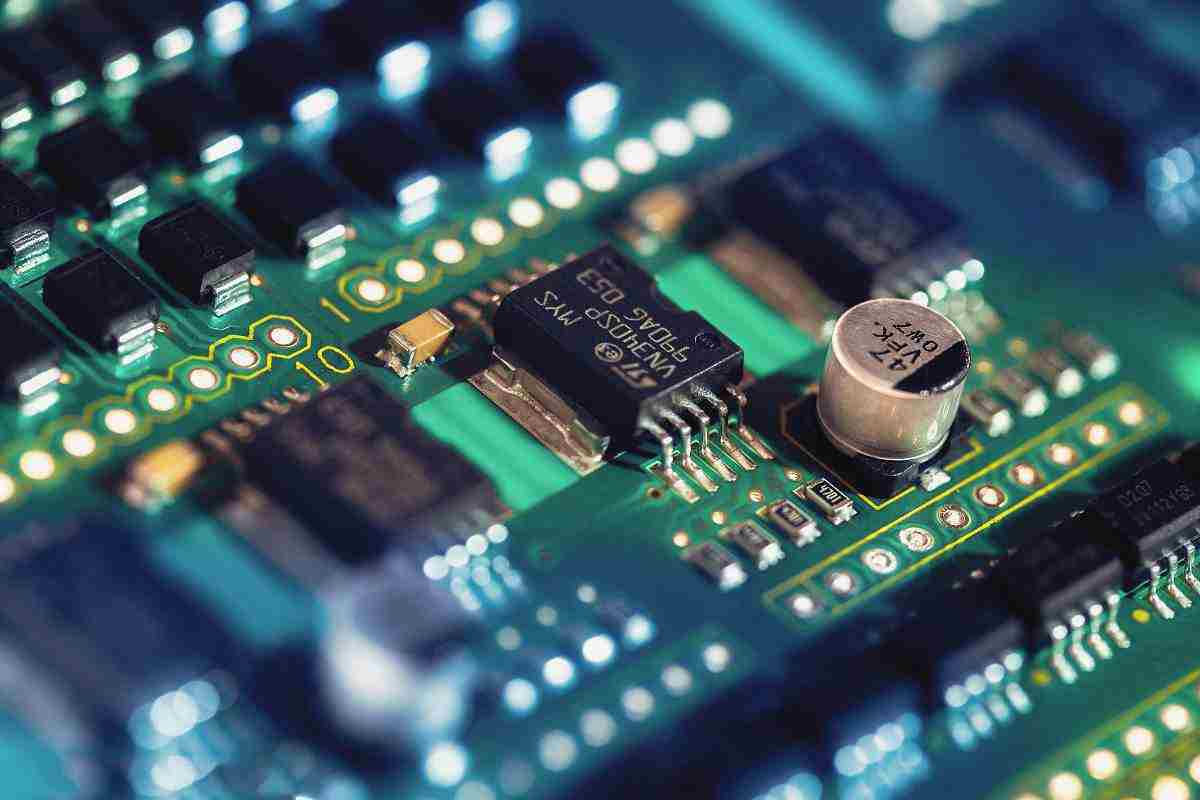

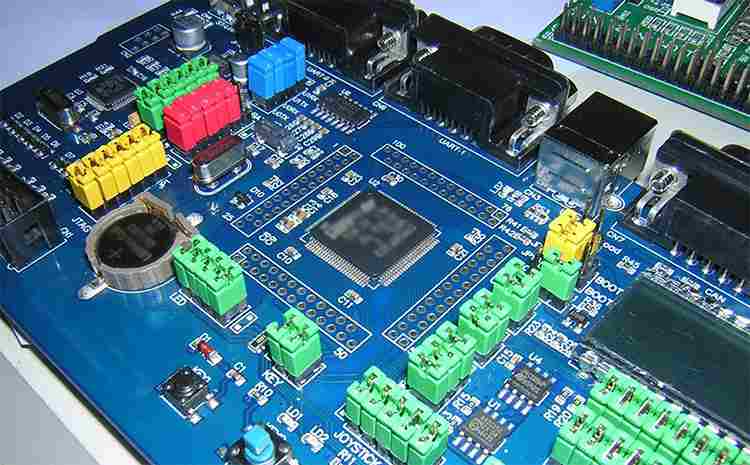

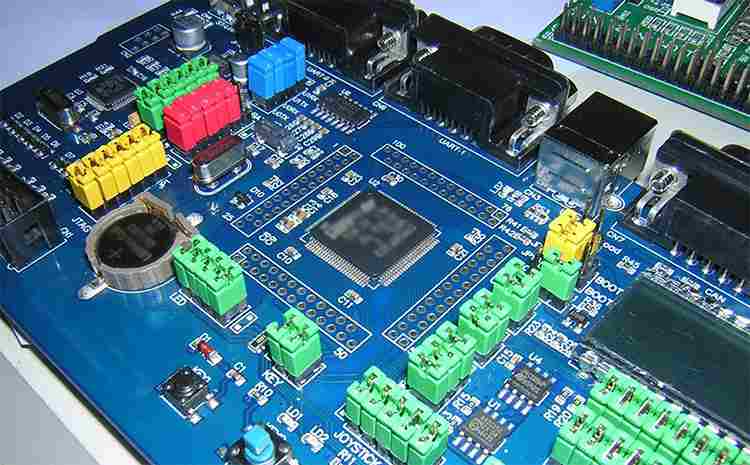

The efficient heat dissipation of PCB electronic components is influenced by the principles of heat transfer and fluid mechanics. The heat dissipation of electrical devices is to control the operating temperature of electronic equipment, so as to ensure the temperature and safety of its work, which mainly involves the heat dissipation, materials and other aspects of different content. At this stage, the main heat dissipation methods are natural, forced, liquid, refrigeration, dredging, heat pipe and so on.

One. natural heat dissipation or cooling mode

Natural heat dissipation or cooling mode is in the natural condition, does not accept the influence of any external auxiliary energy, through the local heating device to the surrounding environment heat dissipation way for temperature control, the main way is heat conduction, convection and radiation concentration, and the main application is convection and natural convection several ways. The natural heat dissipation and cooling mode is mainly used in the electronic components with low temperature control requirements, and the equipment and components with low power consumption and relatively low heat flux of device heating. This method can also be used in sealed and densely assembled devices where other cooling techniques are not required. In some cases, when the requirement of heat dissipation capacity is relatively low, the characteristics of electronic devices will be used to appropriately increase the influence of heat sink and heat conduction or radiation, and the natural convection will be optimized by optimizing the structure, so as to enhance the heat dissipation capacity of the system.

Two. Forced heat dissipation or cooling method

Forced heat dissipation or cooling is a way to accelerate the flow of air around PCB board electronic components through fans and other means to take away heat. This method is relatively simple and convenient, and the application effect is remarkable. This method can be used in electronic components if the space is large enough to allow air flow or to install some cooling facilities. In practice, the main ways to improve such convective heat transfer capacity are as follows: to appropriately increase the total area of heat dissipation, relatively large convective heat transfer coefficient should be generated on the heat dissipation surface.

In practice, increasing the surface area of the radiator is widely used. In the project, the main way is to expand the surface area of the radiator by fin, so as to strengthen the heat transfer effect. The fin heat dissipation mode can be divided into different forms, heat exchangers used on the surface of some heat consumption electronic devices and in the air. Application of this mode can reduce heat sink heat resistance, but also can improve the effect of heat dissipation. For some relatively large power electronic period, it can be used to deal with the turbulence in aviation. By adding a spoiler to the radiator, the effect of heat transfer can be improved by introducing turbulence into the surface flow field of the radiator.

Three, liquid cooling heat dissipation method

Liquid cooling of electronic components is a heat dissipation method based on the formation of chip and chip components. Liquid cooling can be divided into direct cooling and indirect cooling. Indirect liquid cooling is the application of liquid coolant and direct contact with electronic components, through the intermediate media system, the use of liquid module, heat conduction module, injection liquid module and liquid substrate and other auxiliary devices in the transmission of heat elements between. Direct liquid cooling method can also be called immersion cooling method, is the liquid and the relevant electronic components directly contact, through the coolant to absorb heat and take away heat, mainly in some heat consumption volume density is relatively high or in the high temperature environment of the application of the device.

Four, heat dissipation or cooling methods of refrigeration

The cooling method of cooling or cooling method mainly includes phase change cooling of refrigerant and Pcltier refrigeration. In different environments, the way it takes is also different. It should be applied reasonably based on the actual situation. Phase change cooling of refrigerant is a way to absorb a large amount of heat through the phase change of refrigerant, which can cool electronic devices in some specific situations. The general state is mainly through the refrigerant evaporation away the heat in the environment, which mainly includes volume boiling and flow boiling two types. In general, cryogenic technology also has important value and influence in the cooling of electronic components. In some relatively large power computer system can be used in cryogenic technology, not only can improve the cycle efficiency, the number of refrigeration and temperature range is also relatively wide, the structure of the whole machine equipment is relatively compact and the cycle efficiency is relatively high. Pcltier refrigeration uses semiconductor refrigeration to dissipate heat or cool some conventional electronic components. It has the advantages of small size, convenient installation, strong quality, and easy disassembly. This way is also known as thermoelectric refrigeration, is through the semiconductor material itself Pcltier effect, in the direct current through different semiconductor materials in series under the action of electric couple, can absorb heat at both ends of the couple, release heat, so as to achieve the effect of refrigeration. This method is a kind of negative thermal resistance refrigeration technology and means, its stability is relatively high, but because of its relatively high cost, efficiency is relatively low, in some relatively compact volume, and for the refrigeration requirements of the environment. Its heat dissipation temperature ≤100℃; Cooling load ≤300W.

Five, the way of energy channeling in heat dissipation or cooling

The transfer of heat from electronic devices to another environment through heat transfer elements. In the process of electronic circuit integration, the number of high-power electronic devices increases gradually, and the size of electronic devices becomes smaller and smaller. In this regard, it requires that the heat dissipation device itself should have certain heat dissipation conditions, and the heat dissipation device itself should also have certain heat dissipation conditions. Because the heat pipe technology has certain characteristics of thermal conductivity, good isothermal characteristics, has the advantages of heat flux variability and good constant temperature characteristics in application, and can quickly adapt to the environment. It is widely used in the heat dissipation of electronic and electrical equipment, and can effectively meet the characteristics of flexibility, high efficiency and reliability of the heat dissipation device. At present, it is widely used in the cooling of electrical equipment, electronic components and semiconductor components. Heat pipe is a kind of heat transfer mode with high efficiency and phase transformation, which is widely used in the heat dissipation of electronic components. In practice, it is necessary to design the heat pipe separately for different kinds of requirements, and analyze the influence of gravity and external force and other factors. In the process of heat pipe design to analyze the production of materials, technology and cleanliness issues, to strictly control the quality of the product, the temperature monitoring treatment.

Six, heat pipe heat dissipation

Typical heat pipe consists of shell, porous capillary core and working medium. In the vacuum state, the working medium absorbs heat generated by the heat source in the evaporation section and vaporizes. Under the action of tiny pressure difference, the working medium quickly flows to the condensing section and releases latent heat to the cold source and condenses into liquid. The condensing liquid then returns to the evaporation section from the condensing section under the action of capillary suction suction of the liquid core, and then absorbs the heat generated by the heat source. This cycle repeats, transferring heat from the evaporating section to the condensing section. The greatest advantage of heat pipe is that it can transfer a lot of heat in the case of small temperature difference, its relative thermal conductivity is hundreds of times that of copper, known as "near superconducting heat body", but any heat pipe has a heat transfer limit, when the heat of the evaporation end exceeds a certain limit, the working medium in the heat pipe will all vaporize, resulting in the failure of the heat pipe.Because the technology of micro heat pipe is not mature, heat pipe has not been widely used in the cooling of printed circuit board and power electronic equipment.