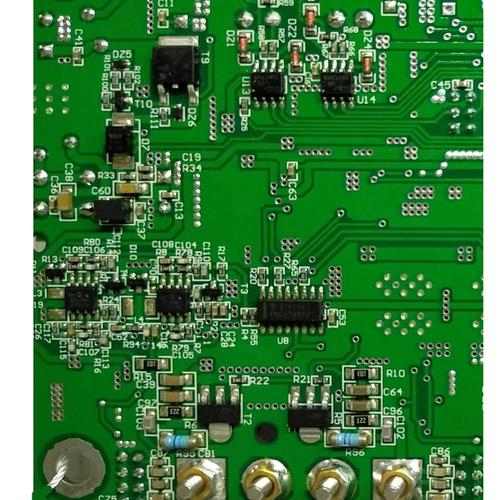

The PCB (Printed Circuit Board) is an important electronic component, the support body of electronic components, and the carrier of electrical connection of electronic components. Because it is produced by electronic printing, it is called "printed" circuit board. Electronic waste, known as "urban mine", is an important secondary renewable resource of non-ferrous metals. Research shows that waste PCB is mainly composed of metal materials and non-metallic materials, metal materials have greater toughness, non-metallic materials have greater brittleness, and because of the toughness and brittleness of the big difference, usually broken to 10mm below the metal dissociation can reach 98%, non-metallic powder used in wood plastic, material, composite material and fire products field.

1. Shredding process: the waste PCB material enters the biaxial shredding machine through the belt conveying equipment, and the large size waste PCB circuit board is processed into about 20mm wide strip block material to meet the requirements of the next rough breaking processing process;

2. Rough breaking process: the material is shredded into strips, through the belt conveyor sent to the rough breaking equipment further processing into 10mm and below granular material, and the screw feeder evenly sent the material to the crusher for grinding processing;

3. Grinding process: granular waste circuit board materials are further refined to achieve the goal of metal and non-metal stripping, in order to meet the requirements of subsequent separation and sorting process;

4. Air separation process: It uses the different specific gravity of non-ferrous materials and non-metallic materials and the principle of air flow rotation centrifuge separation to carry out preliminary separation and sorting of granular materials with different sizes and specific gravity. The fine non-metallic materials with light specific gravity are sorted out and packed into storage, while the mixture of metals and non-metals with larger specific gravity is further homogenized and concentrated. It lays a good foundation for the next selection process.

5. Vibration separation and sorting process: This process belongs to the selection process, that is, in front of the primary process of the coarser particles of metal and non-metal mixture further separation, the principle is through the screen surface a certain frequency of reciprocating vibration and the effect of the wind blowing up suction, so that the metal powder is constantly separated out, the vibration frequency and air volume of this process is adjustable, So the purity of metal powder can also be according to customer requirements and commission, purity of 98%.

6. Environmental protection treatment technology: Because the production line of this equipment is basically composed of crushing equipment and separation and sorting equipment, a large amount of dust and waste gas will be produced during the working process. In order to prevent the pollution of the production site and surrounding environment, the production line of this equipment basically adopts the sealed pipeline negative pressure material conveying method, through the effective combination of cyclone separator, pulse dust collector and fan. Dust and waste gas are collected orderly, dust removal and waste gas purification are carried out in a unified manner, and discharged into the air after environmental protection standards.

"Craftsman spirit", as the guiding principle of manufacturing industry in the new era, "focus, persistence, study, precision, meticulousness..." It is not only the inner spirit of craftsman, but also the standard of green and jie environmental protection equipment. Waste PCB board environmental protection recycling line not only in each production link, each process strict requirements, even every detail carefully thought, the whole process permeates the "craftsman spirit" in the transmission and operation of products, looking forward to enable customers to fully realize the value of products