In PCB design, power supply systems (including relatively high power at relatively low potential) can cause two main problems: One is power supply (or high-potential) noise, that is, in the digital circuit system, the CPU circuit, dynamic memory devices and other digital logic circuit in the process of working the logic state of the high-speed transformation, resulting in the system current and voltage changes of the noise, DC noise when the temperature changes and the noise generated by the power supply itself. The other is ground (or low potential) noise, that is, ground noise caused by the potential difference between ground wires in various parts of the system or by the presence of ground impedance.

The fluctuation of power supply voltage and ground level on PCB can easily lead to peak overshooting or attenuation oscillation of signal waveform, resulting in the noise tolerance of digital IC circuit, and then cause misoperation. The main reason is the voltage drop caused by the switching current of the digital IC and the resistance of the power line and ground wire, as well as the induced voltage drop caused by the distributed inductance of the component pin. The voltage drop caused by the distributed inductance is greater than the line impedance, which is an aspect that must be considered in the design.

When the CMOS part of the PCB is A digital-analog hybrid circuit, such as D/A conversion, when the digital part is connected to the power supply VDD, the electric energy of the VDD will be coupled to the analog part, and part of the VDD voltage will appear on the pin of the analog power supply, which will greatly damage the performance of the whole system and even cause the system to fail to work.

Because of the above reasons, the PCB power wiring should be as wide as possible according to the size of the current, in order to reduce the loop impedance. The use of power layers and strata in multilayer PCBS, while reducing the length of the power line to the power layer or strata. In addition, the direction of power cables and ground cables should be consistent with the direction of data or address lines, which can reduce interference and enhance the anti-noise ability of the system.

prospect

With the development of electronic technology, the system clock and speed are constantly improving. Today's computer systems often have clocks operating at frequencies up to GHz. When the components work at high frequency, in order to adapt to the smaller clock pulse interval, the signal jump along rate is accelerated, so the RF spectrum dispersion is increased, the possibility of EMI interference is increased, and it is difficult to design EMC products. But as long as according to the characteristics of the product and frequency characteristics can always find the corresponding design scheme.

A simple EMI model consists of three factors: the necessary energy source, the necessary receiver, and the coupling path between the receiver and the energy source. Interference is only possible when all three aspects are present. The engineer's task is to decide which element of the system design is the easiest to eliminate, and to implement the idea of eliminating EMI through the corresponding PCB design.

Also, try to use the slowest possible logic system in your design. For example, in most applications, a 74HCT device is sufficient as a temporary replacement for a 74ACT device while having the advantage of producing less RF energy. A general design idea is not to use components that are faster than what is required by function or what the circuit actually requires.

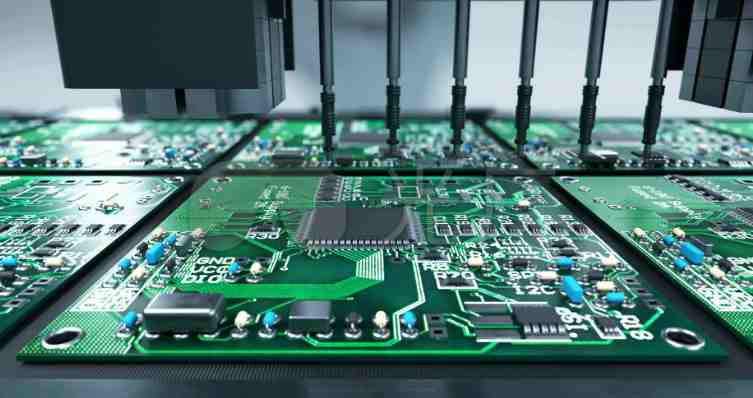

The industrial pcb circuit board belongs to the industrial control industry, mainly the PCB mother board used in industrial applications, its structure usually has many card slots, a large area, a higher degree of modularity, can adapt to a wide range of temperature, a wide range of humidity, and even harsh environment. So, industrial PCB board maintenance needs to have what skills? Let's take a look:

1. Must be proficient in digital and analog electronics. The circuit board is nothing more than resistors, capacitors and other electronic components, along with a main CPU. If the CPU is not damaged, then the circuit board is simply one of the components that is damaged and prevents some aspect from performing the appropriate operation.

2. Have analytical skills. PCB maintenance in circuit board factory is actually the process of finding out the reason and finding out the problem. It takes a lot of time to detect the circuit, and must have a strong logical thinking ability and be targeted. In cases where it is impossible to test every electronic component of the board, and without output, the first step is to look for output signals and then for damage to the output driver section. In this way, the components of the damaged parts can be found step by step.

3. After learning to use all kinds of measuring instruments, it is necessary to learn to use them first, such as multimeters, oscilloscopes, clamp meters, power analyzers etc.