During this period of time, Baiqiancheng Electronics often sees customers come to consult that we need to do PCBA proofing. Among PCBA proofing, some make small batch proofing. They ask whether we can do it, and we have confirmed that we can do it. And also for small and medium-sized batch proofing customized a proofing production line. This production line is equipped with solder paste printing machines imported from Sweden, wave soldering, X-RAY, and professional SMT processing technicians.

In the process of our communication with customers, many customers have big questions on the key points of price when we carry out in-depth communication, why our proofing list is higher and more expensive than the batch price, next, Baiqiancheng Electronic small series will introduce why the price of small-batch proofing in PCBA is more expensive.

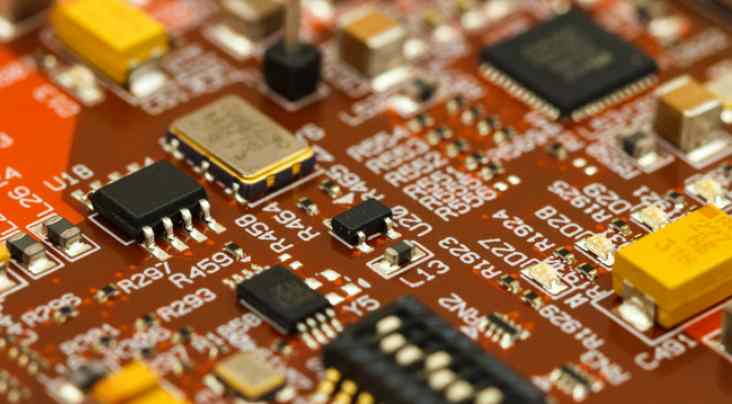

PCBA proofing

Over the years in SMT patch processing factory, we often encounter the situation that customers do not reply messages or contact us because of some details of the quotation. In fact, many customers know that the price of PCBA proofing in small batches is higher than that in batches, but the threshold value in their mind may be one or three yuan higher. After all, we think that a few PCBA or dozens of PCBA is an early proofing to verify whether the functionality of the product meets the design index and customer needs. After all, it is a risky project and I don't want to invest too much. As a smt patch factory, we stand for the sake of customers from the point of view, but ………… .

In fact, when it comes to the price, it must be based on what the SMT factory has done.

Prior to any SMT patch processing, the preliminary work needs to be done is the same, such as material inspection, SMT processor programming, PCB positioning, solder paste printing, SPI solder paste detection, patch processing, first piece confirmation after starting up, etc. At first glance, it looks like a normal process, so what exactly is it?

The disadvantage of small batch PCBA proofing is that SMT patch processing points are too few, tens of thousands of points or hundreds of thousands of points at most, although the online paste is very fast, but procurement, engineering, production, quality, operator, warehouse...... . All departments, personnel and equipment should be moved.

The most important waste is also with the paste is not concentrated, in and out of the line, refueling. Therefore, in the end, according to the minimum consumption of SMT patch processing factory, the cost of processing ten pieces of each PCB board will be quite a sum of money. You think it's still expensive, because you only bought the product for $100. If it is a large quantity of products to share the initial investment of the product, it is very cost-effective.

Therefore, in the case of small amount of PCBA proofing, the so-called loss is more time loss. After all, a skilled operator can earn hundreds of dollars a day. Therefore, under the same time, the production efficiency of SMT patch processing in large quantity is higher, so that we will not waste time on the preliminary work after one morning or one day of production. And in the machine inside out of the time, so as to be efficient, but also greatly save a variety of labor costs, machine loss and so on.

PCBA proofing is the most asked question in the consultation we received. Customers usually ask whether you can PCBA proofing, what is the minimum quantity of proofing and so on. Of course, there are also new customers who are not so familiar with PCBA proofing board, so they always ask whether PCBA proofing board, whether you proofing board and how to charge and so on. The following hundred thousand into electronic speaking PCBA proofing in the patchwork proofing is important?

First of all, time is money in the current society, in order to be more efficient and ensure the quality of products. There is a prescient guarantee of the quality of PCBA products. First of all, the most effective PCBA process is to make samples first. It can not only improve production efficiency, but also reduce production costs.

Second, the panel proofing is a big advantage to reduce the production cost, because the PCBA panel for the whole PCBA processing process will be much less. Such as handling, SMT patch line number and so on. Because the installation of 1/pcs into the machine is also a process, the whole assembly board no matter 20 pieces or 10 pieces, so the production efficiency is undoubtedly the maximum use of production resources and improve the efficiency of production.

The most important thing is that PCBA panel proofing is also of great benefit to our front-end engineering. They can better participate in the production of customers' products and better understand the production difficulty and process difficulty of customers' products. It is of great benefit to the production quality of subsequent products. This early participation helps to control production risks and improve customer satisfaction.

Thirdly, entering the PCBA processing and proofing process in advance can reduce the quality problems that may be encountered in mass production to the greatest extent. After all, ensuring a good reputation is a crucial thing for a company. In particular, PCBA proofing must go through 9 testing procedures and a number of processing procedures.