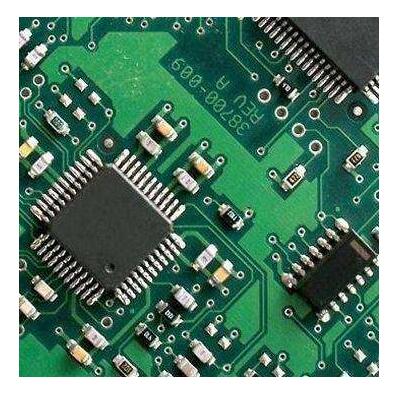

In the process of hardware circuit design, it is inevitable to make mistakes.

Pin error

Series linear regulated power supply is cheaper than switching power supply, but the power conversion efficiency is low. In general, many engineers choose to use linear regulated power sources because they are easy to use and inexpensive. But it's important to note that while it's easy to use, it uses a lot of electricity and causes a lot of heat diffusion. In contrast, switching power supplies are more complex in design but more efficient. However, it should be noted that the output pins of some regulated power supplies may not be compatible with each other, so it is necessary to check the relevant pin definitions in the chip manual before wiring.

Wiring error

The comparison between design and wiring is a major error in the final stage of PCB design. So a number of things need to be checked again, such as device size, hole quality, pad size and review level. In general, repeated validation checks against the design schematic are required.

Corrosion trap

Acid Trap may be formed when the Angle between PCB leads is too small (presenting acute Angle). In the corrosion stage of the circuit board, there may be residual corrosion liquid, which will remove more copper, thus forming stuck points or traps. Later may cause lead fracture, the formation of open circuit. The corrosion trap phenomenon is greatly reduced by the use of photosensitive corrosion solution in modern manufacturing process.

Stele device

In the use of reflux process to weld some small surface paste devices, the device will form a single-end warping phenomenon under the solder infiltration, commonly known as "monument". This phenomenon is usually caused by asymmetrical wiring patterns, resulting in uneven heat diffusion across the device pad. Using the correct DFM check can effectively alleviate the phenomenon of stele.

Lead width

When the PCB lead current exceeds 500mA, the PCB first wire diameter will appear insufficient capacity. For general thickness and width, the wires on the surface of the PCB carry more current than the wires inside the multilayer board, because the surface leads can be diffused by air flow. The width of the line is also related to the thickness of the copper foil in the layer.

Here are some careless mistakes you can make:

1, polarity capacitor, schematic diagram and printed circuit board pin inverted

2, power and ground forget to connect, connect reverse

3. The line sequence of the connector is reversed

4. RX and TX are reversed

5, take for granted to write a package, the result is not this specification of the device. It turns out you can't buy it at all.

6, directly copy the circuit, the result of the device can not be bought.

Once a smart lock team copied the circuit directly from Samsung's smart lock. As a result, a capacitive touch button controller made in South Korea was difficult to buy, and there was no agent and support. It's all about trial and error.

7, the selection of capacitance, only consider the capacity, did not consider the voltage, the result of such a large package can not meet the specifications of the capacitor.

8, when choosing resistance, only look at the resistance value, do not look at power consumption.

9. After drawing the PCB board, look at the fly line by eyes without looking at the DRC report, and the fly line will be real after returning to the board.

10. Reverse packaging

11. The welding resistance layer of the cooling pad is not processed