Circuit board edge removal -- detailed explanation of manual edge removal

Automatic V-cut is generally used for PCB edge removal in PCBA manufacturing process, however, some special boards need manual edge removal. Before using the manual method to remove the edge of the board, it should be confirmed that the board can not be operated with the [V-cut cutter]. Because there are many quality problems when removing the edge manually: the manual folding edge is operated by operators, and it is difficult to control the discipline of folding edge, so the quality will be good and bad. The edge of manual folding plate must be bent, which is easy to cause electronic parts to crack.

Automatic V-cut is generally used for PCB edge removal in PCBA manufacturing process, however, some special boards need manual edge removal. Before using the manual method to remove the edge of the board, it should be confirmed that the board can not be operated with the [V-cut cutter]. Because there are many quality problems when removing the plate edge manually:

Manual folding edges are all operated by operators, so it is difficult to control the discipline of folding edges, and the quality will be good or bad. The edge of manually folded plate must be bent, which is easy to cause electronic parts to crack (micro crack), thus reducing the yield of products. Some problems will not appear until they are used for a period of time.

Manual folding is also easy to cause damage to the circuit board, for example, the connection of vias breaks when the board edge is broken; In addition, it is easy to damage the circuit board. Because the board is broken, there will be burrs at the broken edge. Some circuits may be damaged if they are too close to the board edge.

When manually breaking the board, you need to hold the circuit board, and your fingers will directly contact the electronic parts, thus damaging them. In addition, there is a great opportunity to let the board directly touch the worktable when breaking the board edge, and some relatively high parts are easy to be damaged due to the relationship between breaking and touching.

Precautions for manual folding edge:

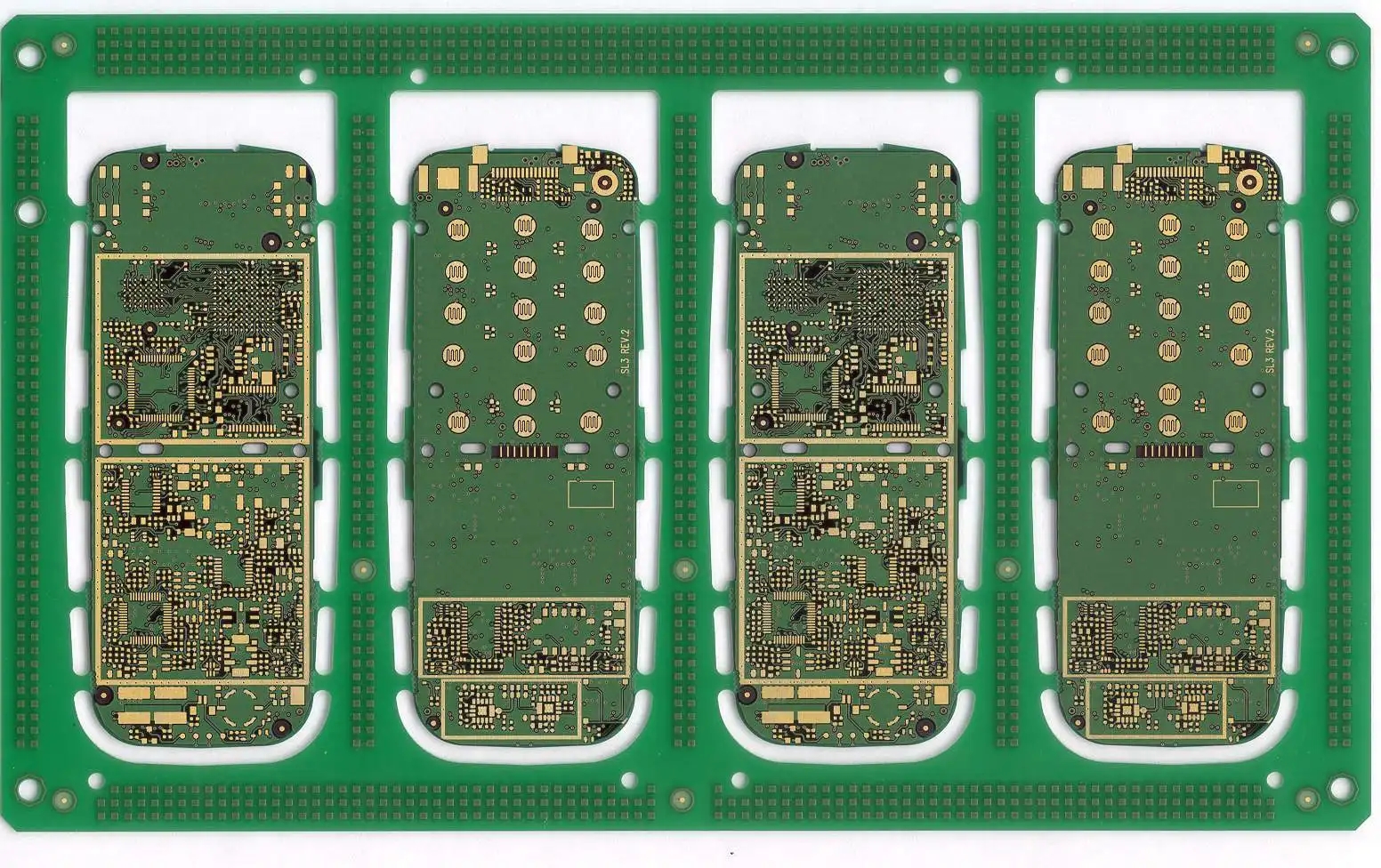

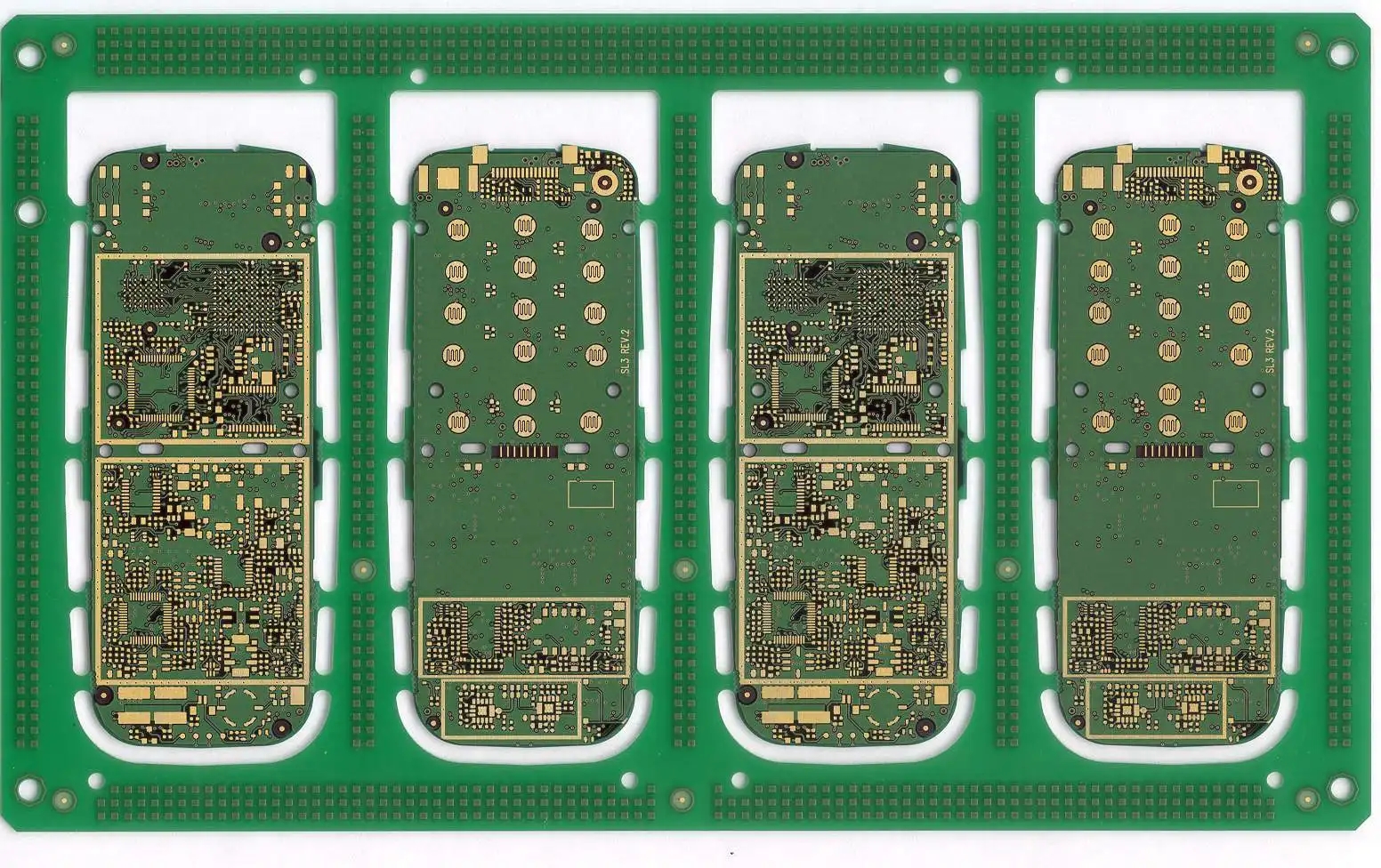

When folding the edge of the board, you must hold the lower edge of the circuit board with both hands, 20mm above the V-cut, and try to avoid bending and deforming the circuit board. The groove depth of manual folding plate edge jig] should match the distance between V-cut and plate edge. In principle, the distance between V-cut and manual folding plate edge jig should not exceed 3mm. The clearance between the circuit board and the manual folding edge fixture should not exceed 1mm.

It is suggested that the folding edge should be turned from the complex side (with large parts and more parts) to the simple side (with fewer parts and smaller parts), so that the thumb can be held on the complex side and the remaining four fingers can be held on the simple side, so as to avoid damaging the parts as much as possible; In addition, it can also prevent damage to large parts caused by accidentally letting the circuit board touch the work table when the board edge is broken.