ESD common sense that a PCB LAYOUTengineer must understand. TVS tube is widely used in practice. Silicon transient voltage absorption diode has extremely fast response time (sub nanosecond level), quite high surge absorption capacity and a lot of voltage grades. It can be used to protect the equipment or circuit from transient voltage generated during static electricity and inductive load switching, as well as over-voltage generated by inductive lightning.

Silicon transient voltage absorption diode (TVS tube)

Precautions for TVS pipe in use:

When there is no TVS tube with proper voltage for use, multiple TVS tubes can be used in series. The maximum current of the series tube depends on the one with the least current absorption capacity. The peak absorption power is equal to the product of the sum of this current and the series tube voltage.

2. For the suppression of repeated transient voltage, it is particularly noteworthy whether the steady state average power of TVS tube is within the safe range. As a semiconductor device, TVS tube should pay attention to the problem of derating when the ambient temperature rises. Pay special attention to the lead length of TVS tube and its relative distance from the protected PCB circuit.

3. The junction capacitance of TVS tube is a key factor affecting its use in high-speed lines. In this case, a TVS tube is generally connected with a fast recovery diode in a back-to-back manner. Since the fast recovery diode has a small junction capacitance, the equivalent capacitance of the two diodes in series is also small, which can meet the requirements of high-frequency use.

4. Solid discharge tube Solid discharge tube is a relatively new transient interference absorption PCB device, which has the characteristics of fast response speed (10~20ns), large absorption current, stable action voltage and long service life. Both solid discharge tube and gas discharge tube belong to energy transfer type. When the external interference is lower than the trigger voltage, the tube is cut off. Once the interference exceeds the trigger voltage, the volt ampere characteristic will turn and enter the negative resistance area. At this time, the current is extremely high and the on resistance is very small, so that the interference energy can be transferred. With the reduction of interference, the discharge tube will quickly go out of the low resistance area and return to the high resistance state to complete a discharge process when the passing current of the discharge tube is lower than the maintenance current through the discharge tube. One of the advantages of solid discharge tube is its short circuit failure mode (when the device fails, the two electrodes are short circuited), which is necessary for many applications and has been widely used at home and abroad. Pcb design training of solid discharge tube has less voltage grade, which is more suitable for network, communication equipment, and even component level protection.

5. For the protection of small current load, the current limiting resistance can be consciously added to the line. As long as the resistance value of the current limiting resistance is appropriate, the normal operation of the line will not be affected, but the current generated by the current limiting resistance on the interference will be greatly reduced. Therefore, it is possible to select TVS tubes with smaller peak power to protect low current load lines.

6. The relationship between the absorbed power (peak value) of transient voltage and the pulse width of transient voltage. It is only the absorbed power (peak value) under a specific pulse width, while the pulse width in the actual line is unpredictable, so it should be estimated in advance. The wide pulse shall be derated.

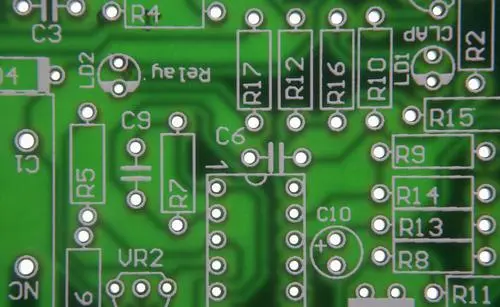

TVS tubes are available in one direction (single diode) and two directions (two diodes connected back to back). Their main parameters are breakdown voltage, leakage current and capacitance. The breakdown voltage of the TVS tube in use is about 10% higher than the working voltage of the protected circuit to prevent the TVS leakage current from affecting the normal operation of the circuit because the working voltage of the line is close to the TVS breakdown voltage; It also prevents the breakdown voltage of TVS tube from falling into the normal working voltage range of the line due to the change of ambient temperature. TVS tube has a variety of packaging forms, such as axial lead products can be used on the power feeder; The dual in-line and surface mount are suitable for the protection of logic circuits, I/O buses and data buses on printed PCB boards.

How to realize PCB precision depth milling control

The key to achieve high-precision PCB depth is that the grating ruler installed on each axis can sense the board surface, so that the falling depth of each Z-axis can be controlled independently, and each axis can coordinate and work independently to achieve mass production processing. The following is an analysis of the main influencing factors:

1. The thickness tolerance of the electric board is required to be 12 ± 0.1mm, and the relationship between the depth accuracy in the Z direction and the horizontal distance that may be affected by it is 0.2/770=0.00026mm per millimeter. When the actual size of the milling figure to be processed is small, this error can be ignored. In the same way, for the thickness error of the base plate, we use melamine wood base plate with good flatness as the base plate instead of milling the wood pulp plate;

2. Because the presser foot pad presses the plate surface, in order to prevent its sliding from scratching the surface of the surface treated plate, a hard cover plate is usually placed on the upper surface of the processed product. We choose a copper free base plate with a good flatness and a thickness of about 1.0mm as the cover plate. The thickness and flatness of the upper cover plate have a great impact on the depth accuracy. It is better to choose a base plate with a smooth and flat surface. The thickness error can be compensated by the first pre processing method. The contact surface of the plastic presser foot will be worn and uneven due to long-term use. In this case, the end face should be polished with sandpaper or replaced with a new pressure foot pad.

3. The measuring needle group can detect the effective cutter length of the upper ring rear milling cutter, and the cutter length deviation of different milling cutters can also be compensated by the pre processing method when the first PCB is used. The influence of the change of effective tool length on the depth accuracy of the gripper can not be ignored, because this deviation is not easy to be found after compensation and adjustment. To avoid this error, generally use a milling cutter for depth milling as much as possible, and do not perform the tool retraction action after each shift of machining is completed within the qualified size range.