Energy Storage Module 150W Inverter PCB Assembly

Name:Energy Storage Module 150W Inverter PCB Assembly

Base Material:Copper

Insulation Materials:Epoxy Resin

Model:Energy Storage Module PCB Assembly

PCB Base:Fr-4

Voltage:DC12V

Color:Customized

Transport Package:Packed in Carton

Specification:RoHS, SGS, UL

Origin:shenzhen

Production Capacity:5000PCS/Month

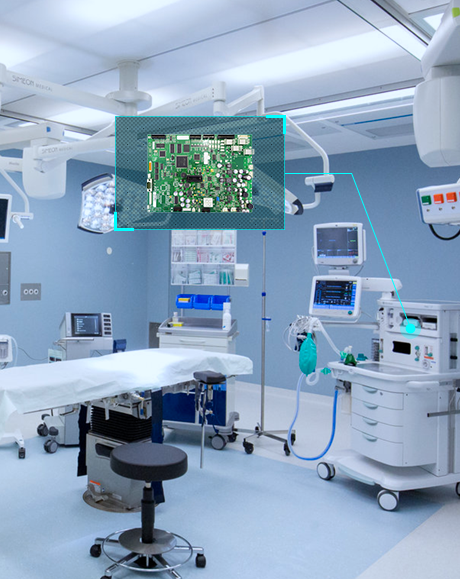

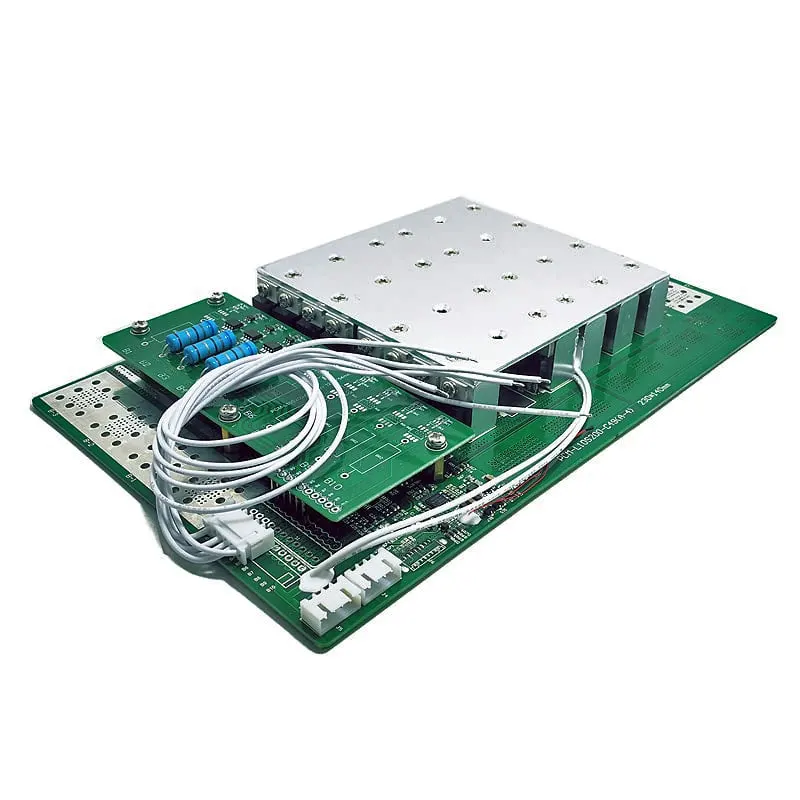

Energy Storage Protection Circuit Module PCB Assembly

Name:Energy Storage Protection Circuit Module PCB Assembly

Specified Types:3-10s Li-ion/Li-Polymer/LiFePO4 Battery

L-Ion/Li-Polymer Charging Voltage:12.6V-42V

LiFePO4 Charging Voltage:10.8V-36V

Max. Continuous Charging Current:150A

Maximal Continuous Discharging Current:150A

Discharge Overcurrent Protection:400±50A(Adjustable)

Colour of PCM:Green

Balance:Yes

Transport Package:Antistatic Bag /White Box and Standard Export Cart

Specification:L230*W140*T35mm

Origin:China Guangdong

Production Capacity:500000/Month

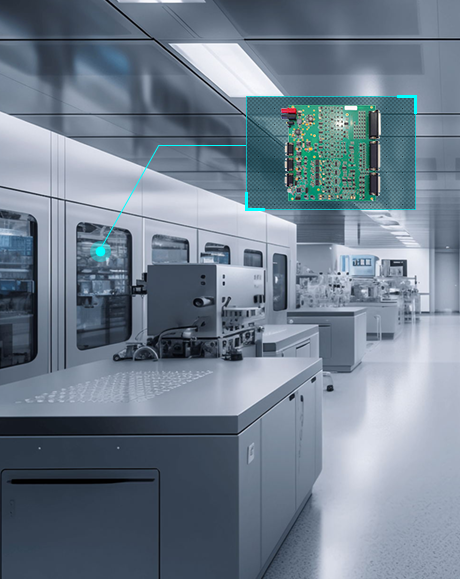

12V to 220v energy storage module PCB Assembly

Name:12V to 220v energy storage module PCB Assembly

Metal Coating:Silver,Copper,Gold,Tin

Mode of Production:SMT

Layers:Multilayer

Base Material:Fr4 Tg130,150,Tg170 /Aluminum

Certification:RoHS, ISO

Customized:Customized

Condition:New

Solder Mask Color:Black、Red、Yellow、White、Blue、Green

Testing Service:Aoi+100% Electrical Test

SMT Efficiency:BGA.Qfp.Sop.Qfn.Plcc.Chip

PCBA Service:One Stop Turnkey PCBA Service

Copper Thickness:1 Oz, 0.5-6oz

Supplier Type:OEM/EMS

Min. Hole Size:0.2mm

Min. Line Spacing:0.075m

Min. Line Width:0.127mm

Layer Available:1-24 Layers PCB Board

Transport Package:Anti-Static Packing

Specification:can make Blind Vias+Controlled Impedance+BGA

Origin:China

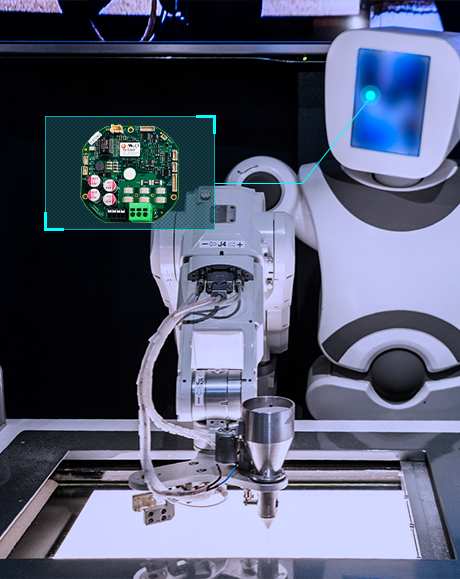

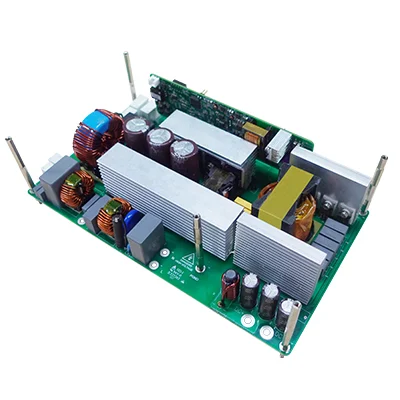

Bidirectional inverter module PCB assembly

Name:Bidirectional inverter module PCB assembly

Efficiency: Maximum Efficiency: 94.5%

Function: with PFC function

Reliability: forward and reverse charging and discharging, high reliability

Standard: RoHS Compliant

Output voltage: high output voltage and current accuracy, better than 1%

Weight: Weight≤2.0kg

Size: 260mm×150mm×65mm

Application: outdoor portable power supply; single-phase inverter; UPS, industrial battery charge and discharge

Description: The 2.2kW high-power bidirectional inverter module INV2200-BD circuit realizes digital power factor correction (PFC), forward LLC, and reverse full-bridge SPWM technology into a two-stage topology, realizes the integration of rectification and inverter, and uses MCU at the same time Programmable control of forward and reverse charging control commands, hardware-level and software-level short-circuit protection, and pure sine wave inverter voltage.

- PCB Assembly Equipment

- PCB Assembly Capability

Automatic solder paste printing machine

AOI Optical Inspection

SMT high-speed placement machine

Nitrogen reflow soldering

x-ray

Three anti-paint spraying machine

SPI Solder Paste Thickness Tester

Automatic wave soldering machine

first article inspection

| SMT capacity: 19 million points/day | ||

| Testing Equipment | X-RAY Nondestructive Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station | |

| Placement speed | Chip placement speed (at best conditions) 0.036 S/piece | |

| Mounted Component Specifications | Pasteable smallest package | |

| Minimum device accuracy | ||

| IC type chip accuracy | ||

| Mounted PCB Specifications | Substrate size | |

| Substrate thickness | ||

| throw rate | 1. Resistance-capacitance ratio 0.3% | |

| 2. IC type without throwing material | ||

| Board Type | POP/common board/FPC/rigid-flex board/metal substrate | |

| DIP daily production capacity | ||

| DIP plug-in production line | 50000 points/day | |

| DIP post welding production line | 20000 points/day | |

| DIP test production line | 50000pcs PCBA/day | |

| Assembly processing capability | ||

| The company has more than 10 advanced assembly production lines, dust-free and anti-static air-conditioning workshop, TP dust-free workshop, equipped with aging room, test room, functional test isolation room, advanced and perfect equipment, can carry out various product assembly, packaging, testing, Aging, etc. production. Monthly production capacity can reach 150,000 to 300,000 sets/month | ||

| PCBA processing capability | ||

| project | Mass processing capability | Small batch processing capability |

| Number of layers (max) | 2-18 | 20-30 |

| Plate type | FR-4, Ceramic Sheet, Aluminum Base Sheet PTFE, Halogen Free Sheet, High Tg Sheet | PTFE, PPO, PPE |

| Rogers,etc Teflon | E-65, ect | |

| Sheet mixing | 4 layers - 6 layers | 6th floor - 8th floor |

| biggest size | 610mm X 1100mm | / |

| Dimensional Accuracy | ±0.13mm | ±0.10mm |

| Plate thickness range | 0.2mm--6.00mm | 0.2mm--8.00mm |

| Thickness tolerance ( t≥0.8mm) | ±8% | ±5% |

| Thickness tolerance (t<0.8mm) | ±10% | ±8% |

| Media thickness | 0.076mm--6.00mm | 0.076mm--0.100mm |

| Minimum line width | 0.10mm | 0.075mm |

| Minimum spacing | 0.10mm | 0.075mm |

| Outer copper thickness | 8.75um--175um | 8.75um--280um |

| Inner layer copper thickness | 17.5um--175um | 0.15mm--0.25mm |

| Drilling hole diameter (mechanical drill) | 0.25mm--6.00mm | 0.15mm--0.25mm |

| Hole diameter (mechanical drill) | 0.20mm--6.00mm | 0.10mm--0.20mm |

| Hole Tolerance (Mechanical Drill) | 0.05mm | / |

| Hole tolerance (mechanical drill) | 0.075mm | 0.050mm |

| Laser Drilling Aperture | 0.10mm | 0.075mm |

| Plate thickness aperture ratio | 10:1 | 12:1 |

| Solder mask type | Photosensitive green, yellow, black, purple, blue, ink | / |

| Minimum Solder Mask Bridge Width | 0.10mm | 0.075mm |

| Minimum Solder Mask Isolation Ring | 0.05mm | 0.025mm |

| Plug hole diameter | 0.25mm--0.60mm | 0.60mm-0.80mm |

| Impedance tolerance | ±10% | ±5% |

| Surface treatment type | Hot air leveling, chemical nickel gold, immersion silver, electroplated nickel gold, chemical immersion tin, gold finger card board | Immersion Tin, OSP |