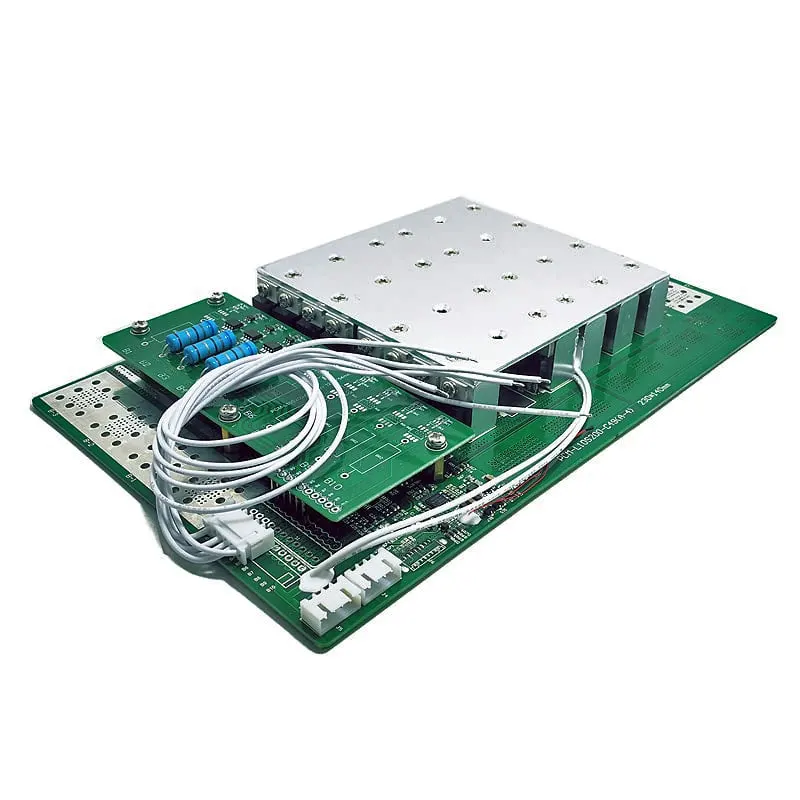

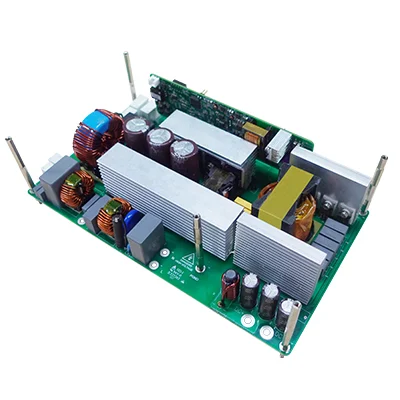

12V to 220v energy storage module PCB Assembly

Name:12V to 220v energy storage module PCB Assembly

Metal Coating:Silver,Copper,Gold,Tin

Mode of Production:SMT

Layers:Multilayer

Base Material:Fr4 Tg130,150,Tg170 /Aluminum

Certification:RoHS, ISO

Customized:Customized

Condition:New

Solder Mask Color:Black、Red、Yellow、White、Blue、Green

Testing Service:Aoi+100% Electrical Test

SMT Efficiency:BGA.Qfp.Sop.Qfn.Plcc.Chip

PCBA Service:One Stop Turnkey PCBA Service

Copper Thickness:1 Oz, 0.5-6oz

Supplier Type:OEM/EMS

Min. Hole Size:0.2mm

Min. Line Spacing:0.075m

Min. Line Width:0.127mm

Layer Available:1-24 Layers PCB Board

Transport Package:Anti-Static Packing

Specification:can make Blind Vias+Controlled Impedance+BGA

Origin:China

Executive Summary

Battery energy storage systems (BESS) can be used for a variety of applications, including frequency regulation, demand response, transmission and distribution infrastructure deferral, integration of renewable energy, and microgrids. Different battery technologies can enable different applications that can provide various benefits to utility services, Independent System Operator (ISO) services, Regional Transmission Organization (RTO) services, and consumer services. This report focuses on the two principal technologies being deployed: lithium-ion and flow batteries.

While each technology has its strengths and weaknesses, lithium-ion has seen the fastest growth and cost declines, thanks in part to the proliferation of electric vehicles. Both lithium-ion and flow battery technologies are projected to see significant cost declines in the coming years. These cost declines coupled with policy incentives will drive increased demand for battery storage from utilities, commercial and industrial (C&I) consumers, and residential consumers, leading to continued growth in the battery market in coming years. Higher penetration of variable renewable generation will drive the need to store the electricity generated during times it cannot be used. Wind energy generation, for instance, tends to be highest in the middle of the night when demand is typically low. The capability to store that energy for use during the daytime when demand is higher can allow for more wind energy to be generated. Similarly, excess solar generation during the middle of the day can be stored to be used later in the evening when demand is higher.

Several electric co-ops are currently deploying BESS, as highlighted by the case studies in this report. Interest among electric co-opsin deploying battery energy storage is growing, and will likely accelerate as more experience is gained, costs continue to fall, and technological advances improve the performance of batteries. Important challenges remain, including developing sustainable business and financing models, overcoming technology performance uncertainty, determining comprehensive and credible cost estimates, warranties and insurance, and integrating battery energy storage with existing utility systems. Some of these challenges will be addressed with the natural maturation of the technology, while others require a broader effort to develop focused programs, projects, tools, and resources.

1: Introduction

Because electricity supply and demand on the power system must always be in balance, real-time energy production across the grid must always match the ever-changing loads. The advent of economical battery energy storage systems (BESS) at scale can now be a major contributor to this balancing process. The BESS industry is also evolving to improve the performance and operational characteristics of new battery technologies.

Energy storage for utilities can take many forms, with pumped hydro-electric comprising roughly 95 percent of the existing storage capacity today.1 In recent years, other technologies, such as batteries, flywheels, compressed air, and localized gravity-based systems, have seen a dramatic surge in research and development (R&D) and deployments. The focus of this report will be on stationary electro-chemical batteries. This covers BESS at the utility, C&I, and residential levels.

Policy support, increased demand from utilities and consumers, and the growth of electric vehicles (EVs) all contribute to falling battery costs and growth in overall BESS capacity. Lithium-ion (liion) batteries have become the dominant form for new BESS installations, thanks to the significant cost declines of battery modules, favorable performance characteristics, flexibility of application, and high energy density.

This document begins by providing an overview of stationary electrochemical BESS applications and technologies, with a specific focus on li-ion and flow batteries. It then presents recent cost trends of li-ion and flow batteries, followed by examining various adoption drivers and growth forecasts. It concludes by providing examples of electric cooperatives that have developed BESS for various applications.

2: Energy Storage Technology Environment

Thissection provides an overviewof the various grid applications of BESS.At the end of the document, several examples of these applicationswithin the electric cooperative network are offered. This section also looks at the major technologies for electrochemical batteries intended for interactive use with or by utilities.

Grid Applications

Most BESS projects are developed with a primary application in mind. However, additional value can be extracted by optimizing the BESS for multiple applications and use cases. 2 This idea is known as value stacking. There are several additional applications that may become more important in the future, but the most common applications today include:

• Demand Side Management/Peak Reduction: Use energy storage to reduce electricity demand during peak demand periods, recharging during low demand periods. This may be implemented by the customer or the utility.

• Electric Service Reliability/ Resilience: Provide backup power during outages, including integration with distributed generation sources.

• Energy Arbitrage: Purchase off-peak electricity at low prices for charging the storage system, so that stored energy can be used or sold at a later time when the price of purchased electricity is high. This is sometimes referred to as electric energy time–shift.

• Fast Response Frequency Regulation: Manage the interchange flows between control areas to maintain frequency within the tolerance bands. FERC Order 755 promotes energy storage as an option for frequency regulation, allowing for a premium to be paid in markets for ancillary services for the rapid response of energy storage to maintain system frequency.

• Micro-grids: The use of dispatchable and non-dispatchable generators, often combined with energy storage, to produce energy for distribution to a local set of loads that can be intentionally islanded from the larger grid. This is usually done for energy resilience or economic optimization purposes.

• Off-grid systems: This applies to systems that are not connected to a utility grid. These range from solar-powered streetlights and mountaintop microwave repeaters to individual homes and even whole communities that are typically located in remote or isolated areas.

• Renewables Firming: Use energy storage in tandem with intermittent wind or solar to provide a more predictable power supply.

• Transmission/Distribution System Deferral: Defer and/or reduce the need to build new generation/distribution capacity or purchase generation capacity in the wholesale electricity marketplace. Distribution applications include deferral of transformer upgrades or line reconductoring.

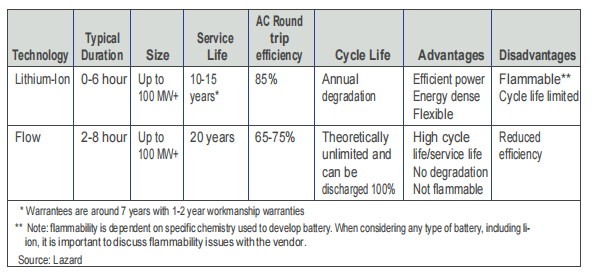

Battery Technologies

Li-ion and flow batteries currently are the two most commercially viable technologies for stationary BESS. Their characteristics are summarized in Table 2.1 and a li-ion installation is shown in Figure 2.1.

TABLE 2.1: Summary of Li-ion and Flow Battery Characteristics

LITHIUM-ION BATTERIES

The vast majority of utility-scale battery systems installed in the U.S. over the past few years have been li-ion, driven largely by cost reductions and power density achieved through electric vehicle manufacturing. Li-ion systems are also popular due to the expected versatility of applications and flexibility of performance (supplying both energy and power).

Multiple configurations of battery chemistries are available for li-ion batteries, making them attractive to electricity providers, especially for applications that require output duration of 4 hours or less. Lithium nickel manganese cobalt (NMC) batteries are the most widely utilized li-ion chemistry for stationary applications. NMC chemistries demonstrate balanced performance characteristics in terms of energy, power, cost, and cycle life. However, lithium-iron-phosphate (LFP) batteries have become increasingly prevalent. The move towards LFP is driven by higher cobalt prices. While LFI does not have the same energy density as NMC, LFI has reduced flammability risk.

Lithium technologies have a high DC round trip efficiency (typically > 85 percent), but experience annual degradation and have a service life of 10 to 15 years.3 However, some battery vendors are currently quoting 20+ year lives for certain chemistries.

Li-ion batteries are used at scales ranging from toys and cell phones to electric vehicles and utilityscale power systems up to 100 MW or larger. While this technology was originally only used for short-time applications, such as frequency regulation or renewables-firming, these batteries are increasingly used in longer duration (2- to 6-hour) applications.

We support 12V to 220v energy storage module PCB Assembly business, Kingford is a professional one-stop PCBA service factory, Welcome to know about our company.

Name:12V to 220v energy storage module PCB Assembly

Metal Coating:Silver,Copper,Gold,Tin

Mode of Production:SMT

Layers:Multilayer

Base Material:Fr4 Tg130,150,Tg170 /Aluminum

Certification:RoHS, ISO

Customized:Customized

Condition:New

Solder Mask Color:Black、Red、Yellow、White、Blue、Green

Testing Service:Aoi+100% Electrical Test

SMT Efficiency:BGA.Qfp.Sop.Qfn.Plcc.Chip

PCBA Service:One Stop Turnkey PCBA Service

Copper Thickness:1 Oz, 0.5-6oz

Supplier Type:OEM/EMS

Min. Hole Size:0.2mm

Min. Line Spacing:0.075m

Min. Line Width:0.127mm

Layer Available:1-24 Layers PCB Board

Transport Package:Anti-Static Packing

Specification:can make Blind Vias+Controlled Impedance+BGA

Origin:China