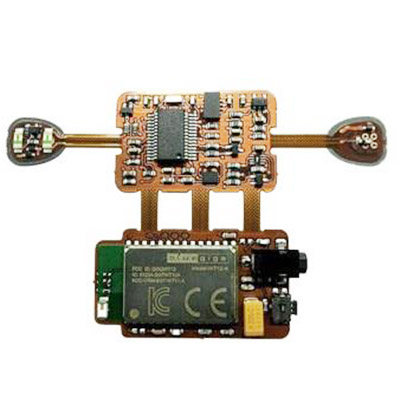

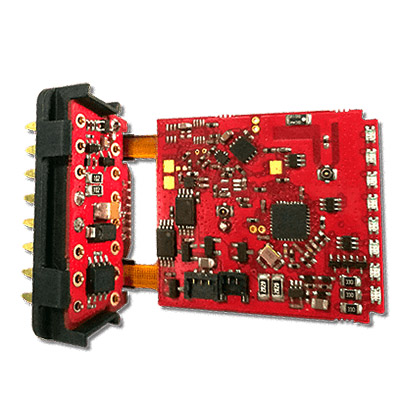

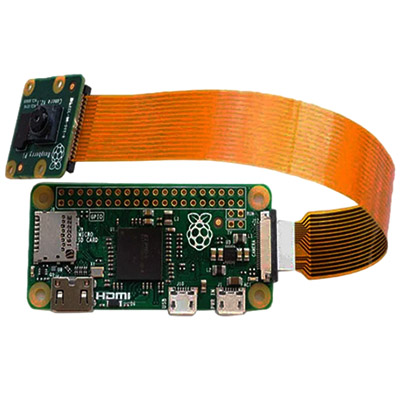

Wireless Charging Module Rigid-Flex PCB Assembly

Name: Wireless Charging Module Rigid-Flex PCB Assembly

Substrate: FR4, FR1, CEM3, Aluminum, TG150, TG170, 94V0

Copper Thickness: 1-4oz

Plate thickness: 0.5-3.2mm

Minimum aperture: 0.15mm

Minimum line width: 0.08mm

Minimum line spacing: 0.08mm

Surface treatment: spray tin, lead-free spray tin, OSP, ENIG, gold

Layers: 1-20 layers

Maximum panel size: 541*647mm

Finished hole size: PTH +/-0.003'', NPTH +/-0.002

Hole Position Accuracy: +/-0.003"

Ring: Min. 0.1mm

Aspect Ratio: Minimum 1:8

Application areas: communication equipment, automotive electronic computers, medical equipment and consumer electronics

Wireless charging technology, derived from wireless power transmission technology, can be divided into two ways: low-power wireless charging and high-power wireless charging.

Low-power wireless charging often uses electromagnetic induction, such as the Qi method of charging mobile phones, but ZTE's electric vehicle wireless charging method uses induction. High-power wireless charging often adopts resonance type (most electric vehicle charging adopts this method), and the power supply equipment (charger) transmits energy to the power-consuming device, and the device uses the received energy to charge the battery and supply its own power at the same time. for operation.

Since the energy is transmitted between the charger and the power-consuming device by a magnetic field, and no wires are connected between the two, the charger and the power-consuming device can have no exposed conductive contacts.

What is the principle of wireless charging?

Wireless charging technology originates from wireless energy transmission technology, which can be divided into low-power wireless charging and high-power wireless charging. The received energy is converted into electricity and stored in the device's battery. Low-power wireless charging often uses electromagnetic induction, such as the Qi method for charging mobile phones. High-power wireless charging often adopts resonant type. Most electric vehicle charging adopts high-power wireless charging. The power supply equipment transmits energy to the device that uses electricity. for operational purposes. Since energy is transmitted between the charger and the electric device using a magnetic field, and the two are not connected by wires, both the charger and the electric device can have no exposed conductive contacts. We provide SMT and PCB Assembly,Rigid-Flex PCB Assembly,Wireless Charging Module Rigid-Flex PCB Assembly services. Kingford is your one-stop flexible circuit assembly company.

We provide SMT and PCB Assembly,Rigid-Flex PCB Assembly,Wireless Charging Module Rigid-Flex PCB Assembly services. Kingford is your one-stop flexible circuit assembly company.

Name: Wireless Charging Module Rigid-Flex PCB Assembly

Substrate: FR4, FR1, CEM3, Aluminum, TG150, TG170, 94V0

Copper Thickness: 1-4oz

Plate thickness: 0.5-3.2mm

Minimum aperture: 0.15mm

Minimum line width: 0.08mm

Minimum line spacing: 0.08mm

Surface treatment: spray tin, lead-free spray tin, OSP, ENIG, gold

Layers: 1-20 layers

Maximum panel size: 541*647mm

Finished hole size: PTH +/-0.003'', NPTH +/-0.002

Hole Position Accuracy: +/-0.003"

Ring: Min. 0.1mm

Aspect Ratio: Minimum 1:8

Application areas: communication equipment, automotive electronic computers, medical equipment and consumer electronics