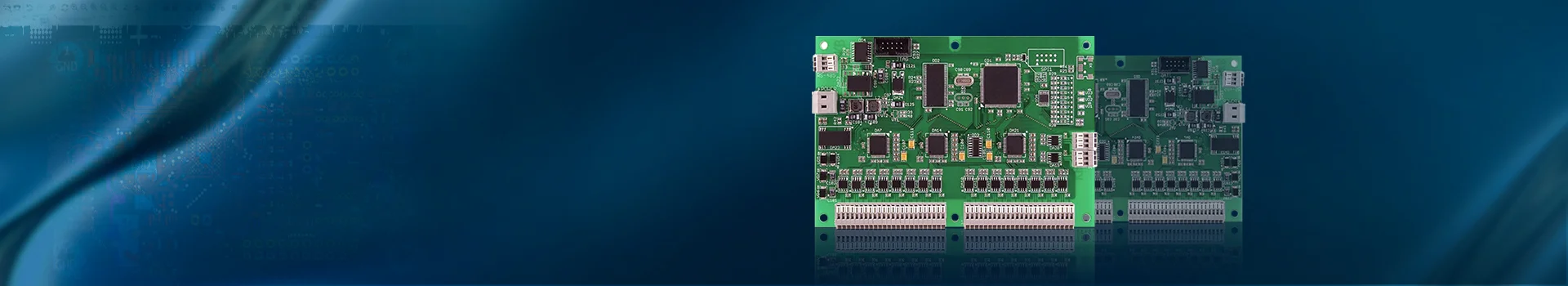

Industrial Control Power Prototype PCB Assembly

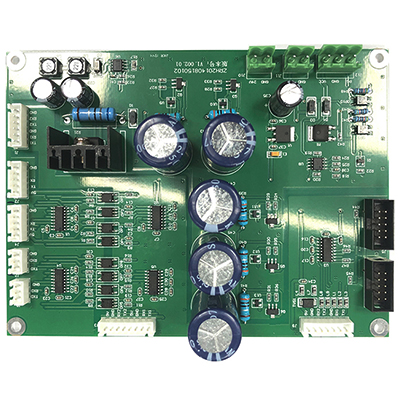

Name: Industrial Control Power Prototype PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products

Industrial control refers to industrial automation control, which is mainly realized by a combination of electronics, machinery, and software. That is industrial control, or factory automation control. It mainly refers to the use of computer technology, microelectronics technology, and electrical means to make the production and manufacturing process of the factory more automated, efficient, precise, and controllable and visible.

The role of industrial control

The emergence and promotion of industrial control technology has brought about the third industrial revolution, which has increased the production speed and efficiency of factories by more than 300%. In the early 1980s, with the spring breeze of reform and opening up, foreign advanced industrial control technology entered mainland China, and the widely used industrial control products include "PLC, frequency converter, servo motor, industrial computer" and so on. These products and technologies have vigorously promoted the automation process of China's manufacturing industry and made great contributions to China's modernization.

The main core areas of industrial control are irreplaceable advantages in large power plants, aerospace, dam construction, industrial temperature control heating, and ceramics.

For example, the real-time monitoring of the power grid needs to collect a large number of data values and perform comprehensive processing. The intervention of industrial control technology facilitates the processing of a large amount of information.

The emergence of industrial control has improved the safety and precision of the manufacturing and construction industries, and solved the original industrial needs such as temperature, pressure, gas flow, and liquid flow. The work that originally required semi-automation and manual work has evolved into automation, including common air switches, pressure transmitters, flow meters, etc.

Working principle of industrial control: For example, the power control of the air switch, when the power of the electrical appliance is too large, the internal mechanical principle starts to run and the switch is automatically disconnected, so as to ensure the safe use of electricity in industries or buildings and accurately find the source of short circuits.

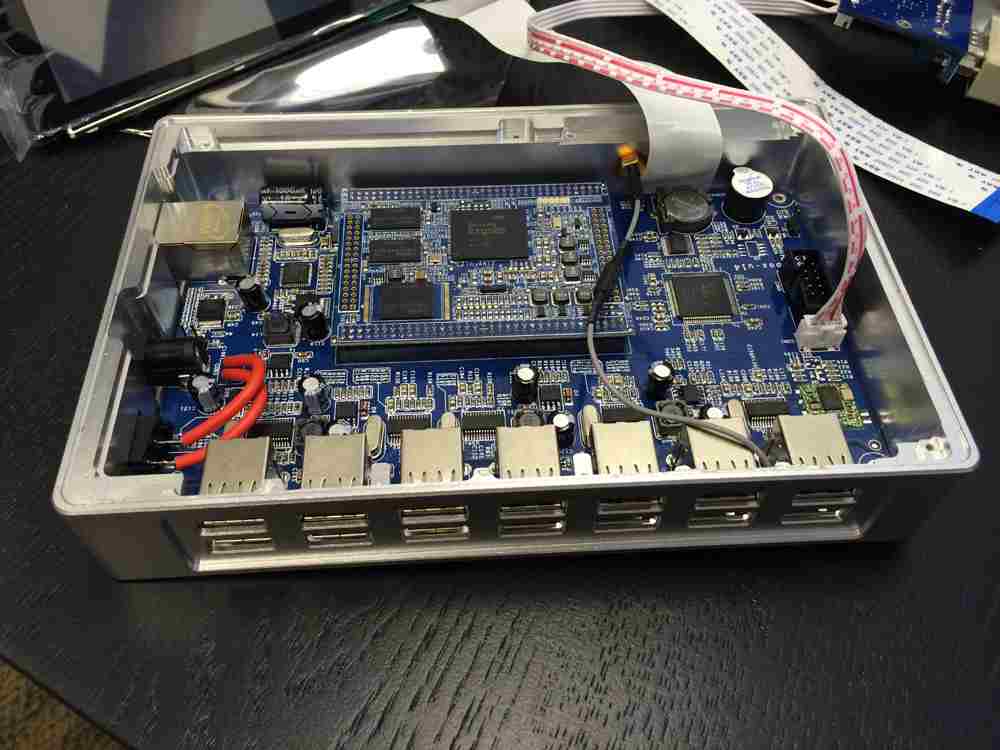

Industrial computer

Industrial control computer is a general term for a tool that uses a bus structure to detect and control the production process and its electromechanical equipment and process equipment. It has important computer attributes and characteristics, such as: computer CPU, hard disk, memory, peripherals and interfaces, real-time operating system, control network and protocols, computing power, friendly man-machine interface, etc. The main components of industrial computer There are five categories: IPC (PC Bus Industrial Computer), PLC (Programmable Control System), DCS (Distributed Control System), FCS (Field Bus System) and CNC (Numerical Control System).

Develop

Industrial control has always been the bottleneck restricting China's equipment industry and even product upgrades. The equipment manufacturing industry is the core and foundation of the industry, which determines the level of a country's industry and technology, as well as its position in the global division of labor.

For industrial master machines such as machine tools, as a domestic manufacturer, Siemens or Mitsubishi is required to provide overall motion control solutions. Core motion control products such as linear motors, AC servo motors and systems are core components for precise motion control or Application solutions are provided by foreign multinational companies as a whole, and everything from products to technologies is designed by foreign companies. Domestic manufacturers engaged in machine tool manufacturing understand the functions of these key components and how to use them more from the perspective of application, and finally integrate them into a set of mechanical equipment. This is the gap in manufacturing and the direction of catching up.

All steel chassis

The all-steel chassis of IPC is designed according to the standard, which is shock-resistant, vibration-resistant, and electromagnetic-interference-resistant, and a passive backplane compatible with PC-bus can be installed inside.

Passive backplane

The slots of the passive backplane consist of bus expansion slots. The bus expansion slot can be composed of multiple slots for extending the ISA bus, PCI bus, PCI-E bus, and PCIMG bus according to the actual application of the user. Versions of various buses have requirements for combination and collocation. For example, the PCIMG1.3 version bus does not provide ISA bus support. The board has a four-layer structure, and the middle two layers are the ground layer and the power layer. This structure can weaken the logic signals on the board. mutual interference and lower source impedance. The backplane can be plugged with various boards, including CPU cards, display cards, control cards, I/O cards, etc.

Industrial power

In the early days, the previous industrial computer based on the Intel Pentium processor mainly used the AT switching power supply, and the ATX power supply was mainly used like the PC, and the average trouble-free running time reached 250,000 hours.

CPU card

There are many kinds of IPC CPU cards, which can be divided into long cards and half-length cards according to the size. Most of them use desktop system processors, such as 386\486\586\PIII in the early days, and now the mainstream is P4, Core Duo, etc. Processor, motherboard users can choose freely according to their own needs. Its main features are: working temperature 0-60 ℃; with hardware "watchdog" timer; also part of the CPU card that requires low power consumption uses an embedded series of CPU.

Other Accessories

Other accessories of IPC are basically compatible with PC, mainly including CPU, memory, graphics card, hard disk, floppy drive, keyboard, mouse, CD-ROM drive, monitor, etc. The standard length of the industrial control chassis is 19 inches and the height is 4U.

Applicable field

IPC has been widely used in all aspects of industry and people's life. For example: control site, road and bridge control toll system, medical equipment, environmental protection monitoring, communication guarantee, intelligent traffic control system, building monitoring and security, voice call center, queuing machine, POS counter cash register, CNC machine tool, fuel dispenser, financial information processing , petrochemical data collection and processing, geophysical prospecting, field portable operations, environmental protection, military industry, electric power, railways, highways, aerospace, subways, intelligent buildings, outdoor advertising, etc.

Features

In layman's terms, industrial computers are computers specially designed for industrial sites, and industrial sites generally have strong vibrations, a lot of dust, and high electromagnetic field interference, and the general factory is continuous operation, that is, a year Generally no rest. Therefore, compared with ordinary computers, industrial computers must have the following characteristics:

① The chassis adopts steel structure, which has high anti-magnetic, dust-proof and impact-proof capabilities.

② There is a special backplane in the chassis, and there are PCI and ISA slots on the backplane.

③ There is a special power supply in the chassis, and the power supply has strong anti-interference ability.

④ It is required to have the ability to work continuously for a long time.

⑤ Generally, a standard chassis that is easy to install is used (4U standard chassis is more common) Note: Except for the above features, the rest are basically the same. In addition, due to the above professional characteristics, the price of industrial computers of the same level is more expensive than that of ordinary computers, but generally there is not much difference.

Disadvantages of Industrial Computers Although industrial computers have unique advantages compared with ordinary commercial computers, their disadvantages are also very obvious - poor data processing capabilities, as follows:

① The configured hard disk capacity is small;

② Low data security;

③ Storage selectivity is small.

④ The price is higher.

PLC

Detailed introduction

The English name of programmable logic controller is Programmable Logic Controller, which was always referred to as PC in the 1970s and 1980s. Since the development of personal computers in the 1990s, it is also referred to as PLC; and the concept of programmable programming covers too much scope, so the American AB company named the programmable controller as the programmable logic controller (PLC-PLC) for the first time. Programmable Logic Controller), for convenience, PLC is still referred to as programmable controller. Some people call the system composed of programmable controllers PCS programmable control system, emphasizing that the programmable controller manufacturers provide people with a complete system.

Market outlook

The development history of PLC

In 1968, GM (General Motors) of the United States proposed to replace the relay control device. In the second year, American Digital Corporation developed the first generation of programmable controllers, which met the requirements of GM's assembly line. With the development of integrated circuit technology and computer technology, there are already fifth-generation PLC products.

In the manufacturing industry characterized by changes in geometry and mechanical properties and in the process industry characterized by physical and chemical changes that convert raw materials into products, in addition to feedback control based on continuous quantities, especially in the manufacturing industry there are Open-loop sequential control based on a large number of switches, which performs sequential actions according to logical conditions; in addition, there is also control of chain protection actions that are not related to sequence and timing according to logical relationships; and a large number of switches, Pulse quantity, timing, counter, analog quantity over-limit alarm and other state quantity-based discrete quantity data acquisition and monitoring. Due to these control and monitoring requirements, PLC has developed into a product that replaces relay circuits and performs sequence control. In years of production practice, PLC, DCS and IPC have gradually formed a tripartite confrontation, as shown in Table 1, and other single-loop intelligent regulators occupy a certain percentage of the market.

From the 1980s to the mid-1990s, it was the fastest growing period for PLC, with an annual growth rate of 30-40%. Due to the improvement of PLC machine contact processing simulation capabilities and network functions, it has squeezed out a part of the DCS market (process control) and gradually monopolized industries such as sewage treatment. However, due to the emergence of industrial PCs (IPCs), especially the development of fieldbus technology , IPC and FCS have also squeezed a part of the PLC market, so the growth rate of PLC is generally slowing down. There are more than 200 manufacturers in the world producing more than 300 varieties of PLC products, mainly used in automobiles (23%), grain processing (16.4%), chemical/pharmaceutical (14.6%), metal/mining (11.5%), pulp/paper (11.3%) %) and other industries.

Market situation of PLC

There are about 30 domestic PLC manufacturers, but they have not formed a large-scale production capacity and brand-name products, and some of them are produced by imitation, assembly of incoming parts or "OEM". Therefore, it can be said that PLC has not formed a manufacturing industry in my country. As a product with no cutting-edge technical difficulty in principle, technology and process, as long as we work hard, we can form a manufacturing industry.

In terms of PLC application, my country is very active. About 100,000 sets of PLC products are newly invested every year, with annual sales of 3 billion yuan, and the application industry is also very wide. However, compared with other countries, more investment is needed in the application of machining and production lines.

The market potential of PLC is huge, not only in our country, but even in industrially developed Japan, surveys show that the proportion of mechatronics products supporting PLC accounts for 42%, and 24% are controlled by relays and contactors. So, there are still many occasions that need to apply PLC, especially in our country.

From the perspective of technological innovation, my country's large and medium-sized enterprises must vigorously develop CIMS (Computer Integrated Manufacturing System), and form FMS flexible manufacturing systems in machinery manufacturing plants. PLC is the foundation, so the PLC market is broad.

PLC has the advantages of stability and reliability, cheap price, complete functions, flexible and convenient application, and convenient operation and maintenance. This is the fundamental reason why it can occupy the market for a long time. We will focus on several issues below and study its development trend.

Hardware software

Classification of PLC

PLC has formed micro, small, medium, large and giant PLCs in the 1990s. According to the number of I/O points, it can be divided into:

l Micro PLC: 32 I/O

l Small PLC: 256 I/O

l Medium PLC: 1024 I/O

l Large PLC: 4096 I/O

l Giant PLC: 8195 I/O

Large-scale systems with a single machine supporting 300 loops and 65,000 I/O points correspond to medium-sized PLCs and above, all of which use 16-32-bit CPUs. Micro and small PLCs originally used 8-bit CPUs. According to communication requirements, some also use 16-bit CPUs. bit ~ 32-bit CPU. Since the sales of PLCs with I/O points below 64 points account for 47% of the entire PLC, those with 64 points to 256 points account for 31%, and add up to 78% of the entire PLC sales, so more research should be done on micro and small PLCs.

PLC hardware

The hardware of the PLC controller itself adopts a building block structure, and the product structure of each manufacturer is similar. Take Omron C200HE of Japan as an example, it is a bus template frame structure, the CPU template is installed on the basic frame (CPU motherboard), and I/O templates are installed in other slots; if there are many I/O templates, the CPU motherboard can be connected via I/O The O expansion cable is connected to the I/O expansion motherboard, and the I/O template is installed on it; another method is to equip a remote I/O slave station, etc. These all show that PLC manufacturers develop all hardware components to users, which is convenient for users to choose and configure into PLCs of different scales. Moreover, the openness of this hardware configuration provides great benefits for manufacturers, distributors (agents), and system integrators. , End users bring a lot of convenience, and bring great convenience to the marketing supply chain. This is a great success experience.

The I/O templates in the PLC, in addition to the general DI/DO, AD/DA templates, have also developed a series of I/O templates with special functions, which opens up the way for PLCs to be used in various industries, such as barcode ASCII/BASIC templates for identification, PID templates for feedback control, high-speed counting templates for operation control and machining, single-axis position control templates, dual-axis position control templates, cam positioner templates, radio frequency identification interface templates, etc., This will be greatly developed in the future. In addition, it will be more perfect in terms of input and output related components, input and output electrical isolation and ground isolation in strong interference situations.

The CPU in the PLC cooperates with the memory to complete the control function. It is different from the DCS system that deals with parameters such as temperature, pressure, and flow. It adopts a fast roving scan cycle, generally 0.1~0.2s, and a faster scan cycle of 50ms or less. It is a digital sampling control system.

PLC software

In order to complete the control strategy, in order to replace the relay, so that the user can complete the control system ladder diagram similar to the relay circuit, a set of control algorithm function blocks (or subroutines), called the instruction system, are compiled in the memory ROM. The user can call it when compiling the application program. The instruction system can be roughly divided into two categories, namely basic instructions and extended instructions. Subdividing the general PLC instruction system includes: basic instructions, timer/counter instructions, shift instructions, transmission instructions, comparison instructions, conversion instructions, BCD operation instructions, binary operation instructions, increment/decrement instructions, logic operation instructions, Special operation instructions, etc., these instructions are mostly similar to assembly language. In addition, PLC has also improved internal resources such as sufficient timers, counters, internal relays, registers and storage areas, which brings great convenience to programming.

Programming language

IEC61131-3

Due to the differences in the instruction system of the products of various PLC manufacturers and the different user requirements in the programming method, the IEC has formulated the Windows-based programming language standard IEC61131-3 (IEC promulgated the international standard IEC1131 for programmable controllers in 1993), which stipulates Five programming languages: Instruction List (IL), Ladder Diagram (LD), Sequential Function Chart (SFC), Function Block Diagram (FBD), and Structured Text (ST). This includes both textual programming (IL, ST) and graphic programming (LD, FBD), while SFC can be used in both types of programming languages.

IEC Technical Committee (TC65) came in to carry out

The IEC61499 project extends IEC61131-3, which is a standard for the architecture of modular distributed systems interconnected through communication networks, and will improve IEC61131-3. This is a standardized document for the openness of programmable logic control devices based on digital technology at a high level, and it is a major trend in the development of PLC.

Development trend

One or several PLCs and PCs are connected to the system, and the PCs play the role of the original programmer and the man-machine interface operation station. This is a new trend in the 1990s, which brings business opportunities for system integration. At the same time, programming software and human Machine interface software (monitoring software or configuration software) and software interface (or driver software) have also been developed.

PLC manufacturers provide the basis of physical layer RS232/422/485 interface on the original CPU template, gradually increase various communication interfaces, and provide a complete communication network. Due to the rapid development of data communication technology, users have strong requirements for openness, and fieldbus technology and Ethernet technology have also developed simultaneously, so the PCS system composed of PLC is slightly better than the openness of DCS. Rockwell AB has formed a multi-layer structure system, that is, Ether Net, Control Net, Device Net and Asi and other field buses (the original DH+ network is also compatible). In addition to the Profibus-DP communication network and the Profibus-FMS network, Siemens proposed the S7 Routing network, that is, the two-layer structure of Profibus-DP and Industrial Enternet. The network is still developing, and our country should have actively invested in it.

In 2001, my country's machinery industry became a new bright spot in industrial development. The total output value increased by 17.15% over the previous year. The output of automobiles ranked top 10 in the world, and the output of machine tools ranked fifth in the world. The profits of the machinery industry increased by 33.35%, accounting for more than 60% of the new profits of the entire industry. Exports also showed encouraging growth. The machinery industry proposes to implement networking. For this point, PLC practitioners should have a clear understanding, and should pay special attention to the openness of networking, the performance/price ratio of network composition, and the reliability, security, and advancement of the network. .

The upward connection of the network is an Internet problem, and the downward connection is a field bus problem. In addition, can the existing network use the Ethernet "e-network to the end" method, the network adopts the client/server method, browser/server method, producer/consumer Way, interface software using OPC way and other issues need to be further implemented. PLC and intelligent MCC motor control center, NC/CNC numerical control equipment supporting CNC machine tools, and other operation control systems, electronic control equipment, frequency converters and soft starters are connected into a system; PLC must cooperate with DCS to act as DCS remote I/O station, etc.; PLC should cooperate with IPC in division of labor. In addition to using IPC as man-machine interface, it is also feasible to use I/O components of software PLC; in addition, PLC and emergency parking safety system (ESD, Emergency Shut Down Systems), the relationship with three-dimensional warehouses, robots, CAD/CAM, etc. must be handled well. In short, PLC must be compatible with various new technologies to make PLC a real "computer".

The application field of PLC is wide, and there are still many fields waiting to be explored urgently, such as being used for customs transit vehicle certification (Shenzhen Yantian), and automatic medicine vending (several Chinese medicine stores) in our country. In addition, PLC can be used in discrete event systems, such as highway network traffic flow (vehicle counting, passenger counting, and dwell time measurement), logistics systems, flexible manufacturing systems (agile manufacturing systems) and all non-standard follow-up service systems. , and then model and take countermeasures and optimize. The future of PLC is bright, and all pessimistic arguments are untenable. As for technological progress, it will take a certain amount of time for PLC to merge with other technologies and disappear!

Intelligent

Overview

As we all know, since the 1960s, western countries have relied on technological progress (that is, new equipment, new technology, and computer applications) to transform traditional industries, resulting in rapid industrial development. The biggest change in the world at the end of the 20th century was the formation of the global market. The global market has led to unprecedented fierce competition, prompting companies to speed up the time to market new products (Time to Market), improve quality (Quality), reduce costs (Cost) and improve service systems (Service). This is the T.Q.C.S. of the enterprise.

Although the computer integrated manufacturing system (CIMS) combines information integration and system integration, and pursues a more complete T.Q.C.S., it enables enterprises to realize "at the right time, the right information is transmitted to the right person in the right way, so that the right decision can be made" , that is, "five correct". However, this kind of automation needs to invest a lot of money. It is a high-investment, high-efficiency and high-risk development model, which is difficult for most small and medium-sized enterprises to adopt. In my country, small and medium-sized enterprises and quasi-large enterprises are still taking the road of low-cost industrial control automation

Automation

Industrial control automation mainly includes three levels, from bottom to top are basic automation, process automation and management automation, the core of which is basic automation and process automation.

In the traditional automation system, the basic automation part is basically monopolized by PLC and DCS, and the process automation and management automation part is mainly composed of various imported process computers or minicomputers. The high prices of its hardware, system software and application software make many Businesses stay away.

Since the 1990s, due to the development of PC-based industrial computers (referred to as industrial PCs), PC-based automation systems composed of industrial PCs, I/O devices, monitoring devices, and control networks have been rapidly popularized and become a reality. An important path to low-cost industrial automation. Almost all large-scale heating furnaces of large enterprises such as Chongqing Iron and Steel Company in my country have also dismantled the original DCS or single-loop digital regulators, and replaced them with industrial PCs to form control systems, and adopted fuzzy control algorithms, which achieved good results.

Market

As PC-based controllers have proven to be as reliable as PLCs and are accepted by operations and maintenance personnel, one manufacturer after another is adopting PC-based control solutions, at least in part of their production. The PC-based control system is easy to install and use, and has advanced diagnostic functions, providing more flexible options for system integrators. From a long-term perspective, the PC-based control system has low maintenance costs.

Because programmable logic controllers (PLCs) are the most threatened by PC control, PLC vendors are uneasy about the use of PCs. In fact, programmable logic controllers (PLCs) have also joined the PC control "wave".

Industrial PCs have developed extremely rapidly in our country. From a global perspective, industrial PCs mainly include two types: IPC industrial computer and CompactPCI industrial computer and their deformation machines, such as AT96 bus industrial computer. Because basic automation and process automation have high requirements on the operation stability, hot plug and redundant configuration of industrial PC, the existing IPC can no longer fully meet the requirements, and will gradually withdraw from this field, and will be replaced by CompactPCI-based industrial computer , while IPC will occupy the management automation layer. In 2001, the state set up a major industrial automation project of "industrialization of open control systems based on industrial control computers". The goal is to develop PC-based control systems with independent intellectual property rights and occupy 30% ( 50% of the domestic market and realize industrialization.

A few years ago, when "soft PLC" appeared, the industry thought that industrial PC would replace PLC. However, today's industrial PC has not replaced PLC, mainly for two reasons: one is the system integration reason; the other is the reason for the software operating system WindowsNT. A successful PC-based control system must have two points: one is that all work must be done by software on one platform; the other is to provide customers with everything they need. It can be predicted that the competition between industrial PCs and PLCs will mainly be in high-end applications, with complex data and high equipment integration. It is impossible for industrial PCs to compete with low-cost micro PLCs, which are the fastest growing segment of the PLC market. From the perspective of development trend, the future of the control system is likely to exist between industrial PC and PLC, and signs of these integrations have already appeared.

Like PLCs, the industrial PC market has remained flat over the past two years. Industrial PC software is cheap compared to PLCs. According to estimates by Frost & Sullivan, in the world's annual industrial PC market of 700 million US dollars, about 85 million US dollars are control software, and 100 million US dollars are operating systems. Will double by 2007, the industry PC market becomes very considerable.

Industrial control industry

The products and technologies of the industrial control industry are very special. Provide reliable, embedded and intelligent industrial computers for other industries. With the continuous deepening of social informatization, it is an intermediate product. Key tasks in key industries will increasingly rely on industrial computers, and IPC-based low-interest industrial control automation is becoming the mainstream, and local industrial computer manufacturers are receiving more and more attention. With the rapid development of electric power, metallurgy, petrochemical, environmental protection, transportation, construction and other industries, from digital home set-top boxes, digital TV, bank teller machines, highway toll systems, gas station management, manufacturing production line control, financial, government, The demand for informatization in industries such as national defense is increasing from time to time, and there is a great demand for industrial computers. The market for industrial computers has a bright future. Let us see what the future of the industrial computer industry will look like.

Develop in a comprehensive direction

Due to the development of standardized data communication lines and communication networks, various single (multiple) loop regulators, PLC, industrial ratio, NC and other industrial control equipment constitute a large system to meet the requirements of factory automation and adapt to the general trend of openness.

Develop towards intelligence

Due to the development of database systems and reasoning functions, especially the application of knowledge base system (KBS) and expert system (ES), such as self-learning control, remote diagnosis and self-optimization, artificial intelligence will be realized at all levels of DCS. Similar to FF fieldbus, intelligent devices based on microprocessors, such as intelligent I/O intelligent PID control, intelligent sensors, transmitters, actuators, intelligent human interfaces and programmable regulators have emerged one after another.

Simple operation direction

For industrial computers, it is best to be able to operate simply, which will also become the future development direction. Simple operation can improve the man-machine interface, simplify programming, use symbol keys on the operation panel, and use dialogue methods as much as possible to facilitate users.

Instrument development

Overview

Industrial control instruments focus on the development of main control system devices based on fieldbus technology, intelligent instruments, special and special automation instruments; comprehensively expand the service field, promote the digitalization, intelligence, and networking of instrumentation systems, and complete the transformation of automation instruments from analog technology to digital With the transformation of technology, the proportion of digital instruments will reach more than 60% within 5 years; promote the commercialization of automation software with independent copyright.

Instrumentation

For electrical instruments and meters, focus on the development of long-life watt-hour meters, electronic watt-hour meters, special-purpose electric measuring instruments and automatic management systems for power grid metering. In 2005, the domestic market share of medium and low-end electrical instruments and meters should reach 95%; by 2010, the domestic market share of high-end and high-end electrical instruments and meters should reach 80%.

Test instrument

Scientific testing instruments focus on the development of process analysis instruments, environmental monitoring instruments and meters, energy-saving analysis instruments for industrial furnaces and kilns, as well as auto parts dynamic balance, dynamic testing and vehicle performance testing instruments, geodetic measuring instruments, and electronic speed measuring instruments required by basic industries , measuring global positioning system and other testing machines, laboratory instruments and other new products. The products are mainly mid-range products with high technical content, which will account for 50% to 60% of the total output value by 2005.

Environmental Instruments

Environmental protection instruments and meters focus on the development of environmental protection monitoring instruments and meters for atmospheric environment and water environment, sampling systems and environmental monitoring automation control system products. In 2005, the technical level reached the international advanced level in the late 1990s, and the domestic market share reached 50% to 60%. , by 2010 the domestic market share will reach more than 70%.

Instrumentation

During the "Tenth Five-Year Plan" of instrumentation components and before 2010, develop a batch of products that are marketable and have good market effects as soon as possible, with a variety share of 70% to 80% and a market share of high-end products of more than 60%; Tackling key problems and developing new products have made the product quality level reach the international level in the late 1990s, and some products are close to the advanced level of similar foreign products.

Electrical measuring instrument

Information technology electrical measuring instruments mainly develop electrical measuring instrument software, intelligent technology, bus-type automatic testing technology, comprehensive automatic testing system, new component measurement technology and testing equipment, online testing technology, information industry product testing technology, multimedia measurement technology And the corresponding testing equipment, electricity monitoring and management technology, etc.

Kingford supports Industrial Control Power Prototype PCB Assembly business, we are a professional PCBA one-stop assembly factory, welcome to place an order.

Name: Industrial Control Power Prototype PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products