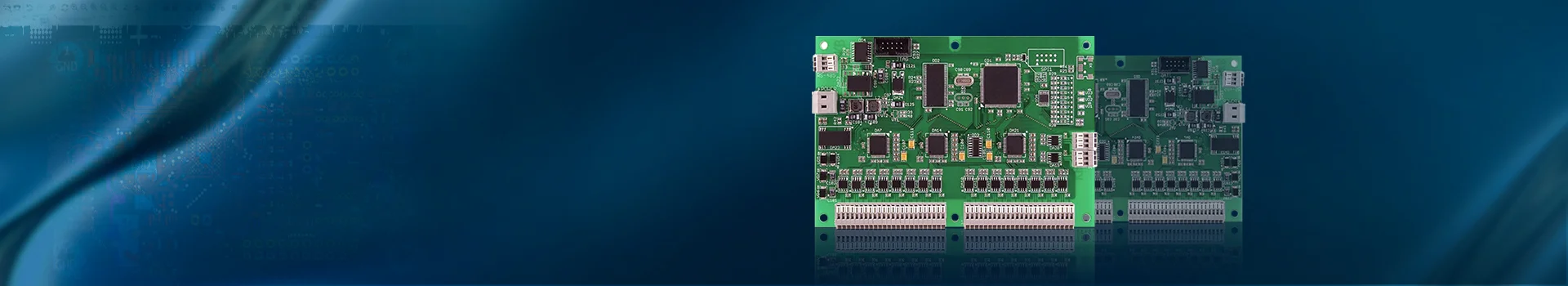

Motor Control Board Prototype PCB Assembly

Name: Motor Control Board Prototype PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products

The motor controller is an integrated circuit that controls the motor to work according to the set direction, speed, angle, and response time through active work.

In electric vehicles, the function of the motor controller is to convert the electric energy stored in the power battery into the electric energy required to drive the motor according to the gear position, accelerator, brake and other instructions to control the starting operation, forward and backward speed, and climbing of the electric vehicle. It may help the electric vehicle to brake and store part of the braking energy in the power battery. It is one of the key components of electric vehicles

CNC programmable stepper motor controller can form a complete stepper motor control system with stepper motor driver and stepper motor, and can control three stepper motors to run in time. This controller adopts computer-style programming language and has input , output, counting and other instructions. It has the characteristics of flexible programming and wide adaptability, and can be widely used in various control automation fields.

Features

This product is composed of high-power intelligent modules, excellent cooling and heat dissipation systems, reliable power control systems, and closed-loop sampling feedback control systems. It has the characteristics of fast response, stable control and operation, and maintenance-free.

Controller principle

Motor controllers use small motors under 300 W in many applications such as automotive, printers, copiers, paper handling machines, factory automation, space and military vehicles, test equipment, and robotics. In general, the output of a motor is approximately inversely proportional to its power, which means that the output of small motors far exceeds that of large motors.

Classification

Motor controllers can be divided into DC motor controllers and AC motor controllers according to their current forms, and motors can be divided into DC motors, brushless DC motors and stepper motors according to their driving methods. The drive can also be divided into a unipolar stepper motor drive circuit and a bipolar stepper motor drive circuit.

Scope

The most widely used small motors include DC motors, brushless DC motors and stepper motors. The main difference between stepper motors, DC motors, and BLDC motors is how they are driven.

Kingford provides Motor Control Board Prototype PCB Assembly services. This is a PCBA one-stop assembly factory with senior industry experience. Welcome to know us.

Name: Motor Control Board Prototype PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products