PCBA process flow

In simple terms, what is a PCB?

PCB=printed circuit board; the Chinese name is printed circuit board, also known as printed circuit board, which is an important electronic component, a support for electronic components, and a carrier for electrical connection of electronic components. Because it is made using electronic printing, it is called a "printed" circuit board. the

What is PCBA?

PCBA=assembly of PCB. Various electronic devices are assembled on the circuit board through the surface packaging process. Next is box assembly, which is to assemble the assembled PCB with the shell to form a finished product. That is to say, the empty PCB board goes through the SMT upper part, and then goes through the whole process of DIP plug-in, referred to as PCBA. This is a commonly used way of writing in China, while the standard way of writing in Europe and America is PCB'A, with a slanted point added. PCBA is a PCB with a chip attached. the

What is the difference between PCB and PCBA?

PCB refers to circuit board, while PCBA refers to circuit board plug-in assembly, SMT process. the

One is a finished board and the other is a bare board

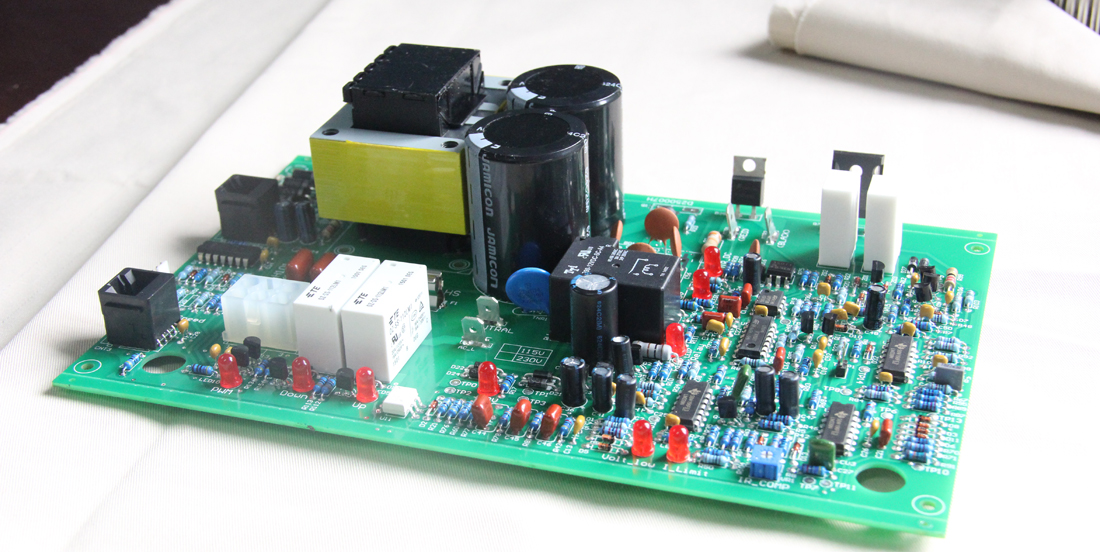

PCB (Printed Circuit Board) is called "printed circuit board". It is made of epoxy glass resin material. It is divided into 4, 6, and 8-layer boards according to the number of signal layers, and 4- and 6-layer boards are the most common. SMD components such as chips are attached to the PCB. PCBA may be understood as a finished circuit board, that is, a PCBA can only be counted after all the processes on the circuit board are completed. the

PCBA=Printed Circuit Board +Assembly. the

That is to say, the empty PCB board goes through the SMT upper part, and then goes through the whole process of DIP plug-in, referred to as PCBA. the

PCB (Printed Circuie Board) is the abbreviation of printed circuit board. It is usually called a printed circuit on an insulating material, according to a predetermined design, to make a printed circuit, a printed component, or a combination of the two. The conductive pattern that provides electrical connection between components on an insulating substrate is called a printed circuit. In this way, the finished board of printed circuit or printed circuit is called printed circuit board, also known as printed board or printed circuit board.

PCBAs

The process is the combination of SMT processing process and DIP processing process. According to the requirements of different production technologies, it can be divided into single-sided SMT placement process, single-sided DIP insertion process, single-sided mixed assembly process, and single-sided placement and insertion. process, double-sided SMT placement process and double-sided mixed assembly process, etc.

PCBA Process Flow Chart Single-sided SMT Mounting Single-sided DIP Inserting Single-sided Mixing Single-sided Mounting and Inserting Mixed Double-sided SMT Mounting Double-sided Mixed

The PCBA process involves the processes of carrier board, printing, SMT, reflow soldering, plug-in, wave soldering, testing and quality inspection, etc. See the following PCBA process flow chart for details

PCBA process flow chart

Different types of PCB boards have many different processes. The following will elaborate on the differences in various situations.

1. Single-sided SMT placement

Solder paste is added to the component pad, and after the solder paste printing of the bare PCB is completed, its related electronic components are mounted by reflow soldering, and then reflow soldering is performed.

2. Single-sided DIP plug-in

The PCB board that needs to be plugged in is wave soldered after the production line workers insert the electronic components, and then cut the feet and wash the board after soldering and fixing. However, the production efficiency of wave soldering is low.

3. Single side mixed

Solder paste printing is performed on the PCB board, and electronic components are mounted and fixed by reflow soldering. After the quality inspection is completed, DIP insertion is performed, and then wave soldering or manual soldering is performed. If there are fewer through-hole components, manual soldering is recommended. .

4. Mixed single-sided mount and plug-in

Some PCB boards are double-sided, mounted on one side and inserted on the other. The process flow of placement and insertion is the same as that of single-sided processing, but fixtures are required for PCB reflow soldering and wave soldering.

5. Double-sided SMT placement

In order to ensure the aesthetics and functionality of the PCB board, some PCB design engineers will use double-sided mounting. Among them, IC components are arranged on the A side, and chip components are mounted on the B side. Make full use of the PCB board space to minimize the PCB board area.

6. Double-sided mixed packing

There are two methods for double-sided mixed assembly. The first method is PCBA assembly, which is heated three times. The efficiency is low, and the pass rate of wave soldering using red glue is low. It is not recommended. The second method is suitable for the situation where there are many double-sided SMD components and few THT components. It is recommended to use manual soldering. If there are many THT components, wave soldering is recommended.

The above only simplifies the PCBA assembly process of the printed circuit board, and shows its manufacturing process in a graphic way. However, as the PCBA assembly process and production process are gradually optimized, its failure rate is also continuously reduced to ensure the production of high-quality finished products. The quality of the solder joints of all the electronic components mentioned above determines the quality of the PCBA board. Therefore, when relevant electronics manufacturers are looking for PCBA assembly and processing manufacturers, it is best to require experienced and high-level processing equipment.