The double-sided aluminum substrate is divided into three layers: the first layer is copper moor, the second layer is thermal insulation material, and the third layer is aluminum plate.

The roles of the three layers of the double-sided aluminum substrate are respectively; The first layer is used for electrical circuits. The second layer is the key to whether the heat generated by the LED can be quickly transferred to the aluminum plate, which depends on the thermal resistance of this heat-conducting insulating material. The function of the third layer is to transfer the heat from the thermal insulation material to the lamp cup again. There is also an installation role. So we know how to do better heat dissipation of the lamp cup, because we understand the heat dissipation characteristics of the lamp cup. And there is no more concern about aluminum substrate, there is no more understanding. Some believe that whether the heat conduction of aluminum substrate is better is related to the thickness of aluminum plate. This is not the case. In order to improve the thermal conductivity of aluminum substrate, the most critical is to improve the performance of thermal insulation materials. The thermal resistance of heat-conducting insulating materials should be reduced. It is not a simple matter to reduce the thermal resistance of insulating materials, which is affected by the material composition and manufacturing process.

In the production of FPC, the initial design involves the selection of substrate, protective film and reinforcement type. These materials have a variety of specifications, and electronic engineers combine the use of environment, impedance, through the current and other factors to choose. High precision single and double circuit board substrates are mainly divided into calendered copper and electrolytic copper. Calendered copper has good flexibility and bending resistance, but its overcurrent is smaller than that of electrolytic copper. Electrolytic copper is hard in texture and poor in flexibility compared with calendered copper, but it can overcurrent is larger. It is generally used in this aspect of power supply. From the number of layers, it is divided into single - sided substrate and double - sided substrate. Single-side substrate is composed of polyimide resin, and PI, pressed copper foil on one side, pressed surface containing glue is called rubber calendering, rubber electrolysis, no glue is called rubber calendering or rubber electrolysis. The main difference is that copper foil and insulation PI adsorption capacity is different and different breakdown coefficient. As for thickness, copper foil is available in 1oz(35um), 0.5oz(18um), 1./3oz(12.5um), and insulation PI thickness is generally 12.5um, 25um. The base material thickness mainly has three different thicknesses: 35/25, 18/12.5 and 12.5/12.5.

Protective film or polyimide resin, that is, PI, the common thickness of the main or 27.5um (12.5umPI+15um glue), 50um (25umPI+25um glue), there are three main colors, the most used is brown yellow, followed by black and white, which black and bright light and matte distinction.

Reinforcing plate high frequency plate

The reinforcing sheet used in FPC is mainly three kinds, polyimide resin (PI), glass fiber board (FR-4), steel sheet. Different reinforcing environments are different. PI is soft in texture, smooth in surface and thin in thickness (0.0275-0.3mm), and has little damage to the interface. Therefore, it is mainly used to strengthen the insertion and extraction area of the gold finger, so as to improve the insertion and extraction times and prolong the life of FPC and interface. FR-4 texture is hard, the thickness of the common 0.2-2.0mm, thickness interval is larger, so it is mainly used to strengthen the back of the pad, strengthen the reliability of welding; Steel sheet is mainly the most hard texture, good texture, conductive, used for grounding design.

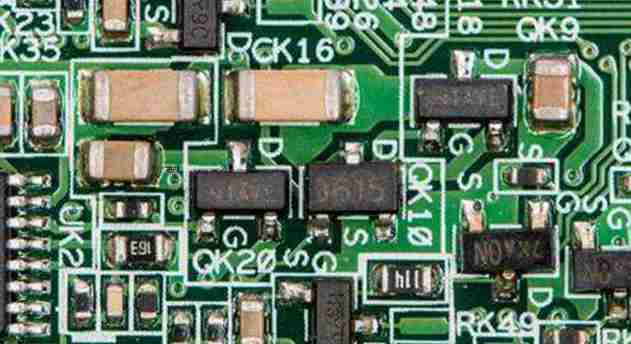

Circuit board classification

【PCB Circuit board 】

PCB single panel, CB double panel, PCB 4-layer board, PCB 6-layer board, multilayer circuit board, audio PCB board, IC card board, mobile phone camera board, PCB backlight board, LED display circuit board, high frequency board, FR4 lamp, strip board

【FPC Circuit Board 】

FPC single panel, FPC double panel, FPC multilayer board, FPC camera board, FPC touch screen board, FPC backlight board, FPC module board, FPC hollow board, LED soft light strip board, soft and hard combined board, FPC mobile phone keys, LED module circuit board

Single-sided aluminum substrate, double-sided aluminum substrate, annular aluminum substrate, hexagonal aluminum substrate, LED aluminum substrate, high power aluminum substrate, high thermal conductivity aluminum substrate, heat dissipation aluminum substrate, 500mm aluminum substrate, 1200mm aluminum substrate, silver plated aluminum substrate, tin spray aluminum substrate, street lamp aluminum substrate, metal core plate, LED lamp strip aluminum substrate