With the rapid development of science and technology today, PCBA assembly plant is an increasingly important industry. It can precisely assemble a number of different materials and components into a complete complete machine to meet the needs of customers. However, precision assembly and quality control are important considerations for assembly plants. So, what is precision assembly and quality control in PCBA assembly plant? Here we will introduce one by one:

First, precise assembly

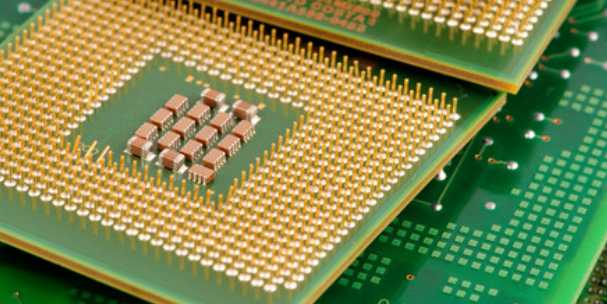

Precision assembly refers to the precise assembly of multiple parts to meet customer needs and expected requirements. Accurate assembly needs to be performed by professional technicians, who need to master various techniques such as tin contacts, welding, potting, etc., to ensure the assembly quality. In addition, the PCBA assembly plant also provides professional training for assembly technicians to ensure that they are up to date with the latest assembly technology, thus ensuring assembly quality.

2. Quality control

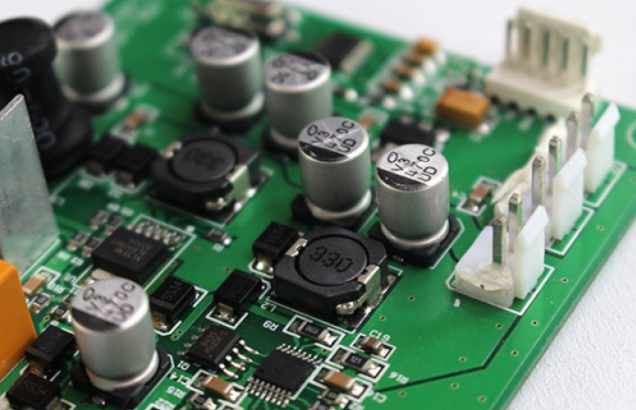

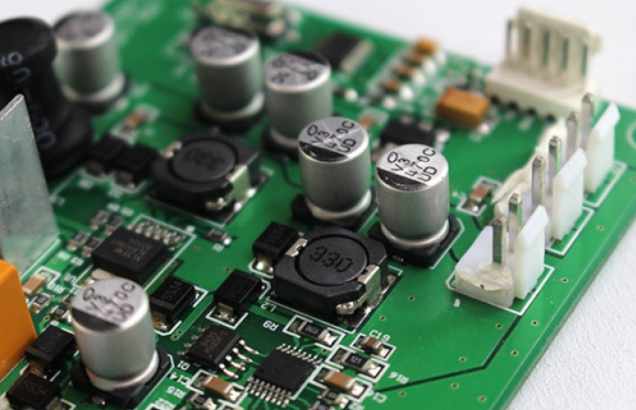

Quality control refers to the PCBA assembly plant after the completion of assembly, through a comprehensive quality inspection to ensure the quality of products. Quality control is usually done by professional engineers and technicians who are familiar with PCBA assembly and quality control techniques to ensure that quality standards are met. PCBA assembly plants can also utilize the latest quality inspection equipment and technology, such as X-ray inspection, manipulator and robot, etc., to ensure assembly quality.

Iii. Testing

Testing means placing a product in a specific environment and conducting a series of experiments to test its characteristics, reliability and functionality. Testing helps PCBA assembly plants find defects in the assembly process so that they can be corrected in time to ensure product quality. PCBA assembly plants can also use the latest test equipment and technology, such as X-ray machines, hot disk detection machines, etc., to ensure the reliability and functionality of products.

To sum up:

To sum up, precision assembly and quality control are important considerations for PCBA assembly plants. PCBA assembly plants need to master a variety of technologies, such as precision assembly, quality control and testing, to ensure product quality. In addition, the latest technology and equipment can be used to improve the quality and reliability of PCBA assembly.

2. Three key knowledge points you need to know about PCBA assembly plant

With the acceleration of industrial development, PCBA assembly plant is increasingly becoming one of the core projects pursued by industry investors. However, before investing, investors need to understand three key knowledge points about PCBA assembly plants so that they can ensure good investment decisions are made:

1. Type of assembly plant

The type of PCBA assembly plant determines the type of products and equipment it produces, which can be divided into circuit board assembly plant, module assembly plant, intermediate equipment assembly plant, complete product assembly plant and other electronic product assembly plant according to specific uses. Investors need to determine the type of products produced according to the demand in order to choose the right type of assembly plant.

Two, assembly plant equipment

The equipment in the PCBA assembly plant is the basis of the assembly plant, consisting of dozens of different functional equipment, using different equipment according to different assembly plant types. Investors need to choose the right equipment based on the type of assembly plant in order to meet demand and spend their money efficiently.

Three, the assembly plant quality

The quality of PCBA assembly plant is an important index to measure its production capacity, which is mainly reflected in its production process, debugging design ability and quality control ability, etc. Only by evaluating the assembly plant through relevant quality indicators, can we determine whether it is suitable for this investment.

summarize

An investment in a PCBA assembly plant is a medium risk. Therefore, before investing in a PCBA assembly plant, an investor needs to know three key knowledge points about the assembly plant, including the type, equipment and quality of the assembly plant, in order to ensure that the right investment decision can be made.