Integrated circuit is used in all kinds of circuits. Integrated circuit pins are dense and not easy to dissolder. As a general maintenance master or electronic technology practitioners, how to weld integrated circuits?

Method/procedure

1. Dual in-line integrated circuit, you can use two electric irons, at the same time adding tin to the two columns of pins for simultaneous heating disassembly.

2. For the next plug-in integrated circuit, solder must be left on the circuit board, resulting in blocked welding holes. We generally use suction guns to clean up the residue of welding holes.

3. If you can judge that the integrated circuit has been damaged and the integrated circuit needs to be replaced, you can use a sharp tool to cut off the pins of the integrated circuit, and then use a soldering iron to clean the remaining pins on the circuit board.

4. In addition to the disassembly of integrated circuits, the commonly used tweezers and magnifying glasses are necessary, otherwise only the eyes can not be implemented.

5. The heat gun is very convenient for welding and disassembly of the patch type integrated circuit. It can heat the whole module of the integrated circuit in the whole area, so that each welding point is easily heated evenly and the disassembly is successful

6. There are some other disassembly and welding methods, such as BGA integrated circuit, welding and disassembly are not easy things, need special tools to complete.

How to weld integrated circuit board

Disassembly and welding techniques for chip integrated circuits

The disassembly process of the chip integrated circuit is as follows:

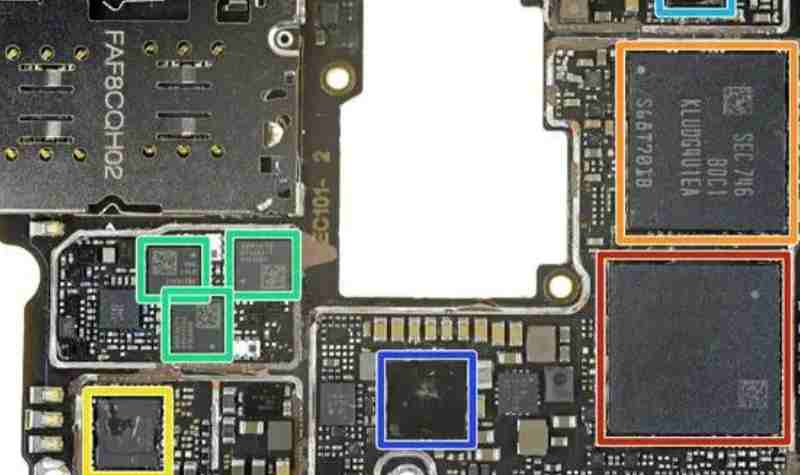

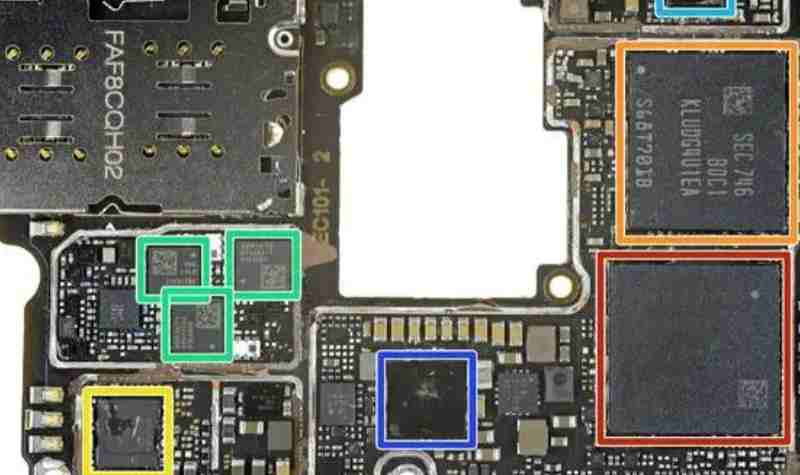

① Before disassembly, carefully observe the position and orientation of the integrated circuit to be disassembled on the circuit board, and make marks, so that the integrated circuit can be installed according to the corresponding marks during welding, to avoid installation errors.

② Clean up the impurities around the patch integrated circuit with a small brush, and then apply a little rosin powder or rosin water to the patch integrated circuit pin.

③ Adjust the temperature and wind speed of the heat gun. The temperature switch is generally adjusted to 3 ~ 5, and the wind speed switch to 2 ~ 3.

(4) When disassembling with a single sprinkler head, attention should be paid to keep the sprinkler head and the dismantled integrated circuit vertical, and move along the pins around the integrated circuit, evenly heating the pins, the sprinkler head can not touch the integrated circuit and surrounding peripheral components, blow welding position should be accurate, and can not blow to the components around the integrated circuit.

(5)After all the solder of the pins of the integrated circuit is melted, use tweezers to lift or clip the integrated circuit, and do not force, otherwise it is easy to damage the copper foil connected with the integrated circuit.

For maintenance personnel who do not have a hot air welding table or a hot air gun, the following methods can be used to remove the chip integrated circuit: First, a column of pins of integrated circuit is coated with rosin, and all the pins of the column are connected with solder, and then the solder iron is heated. After the solder on the column of pins is melted, the thin blade (such as a razor blade) is pushed between the circuit board and the pins, and the electric iron is removed, and the blade is taken out after a few seconds. In this way, the column of pins of integrated circuit is separated from the circuit board. Then use the same method to separate the other pins of the integrated circuit from the circuit board, and finally you can remove the entire integrated circuit.

How to weld integrated circuit board

The welding process of the chip integrated circuit is as follows:

(1) Smooth the solder joints on the circuit board with an electric soldering iron. If necessary, the solder joints should be filled with tin, and then clean the impurities around the solder joints with alcohol.

(2) The integrated circuit to be welded and the welding position on the circuit board are good, and then weld the four diagonal pins of the integrated circuit with an electric soldering iron. The integrated circuit is fixed, and the pins are coated with rosin or sprinkled with rosin powder.

(3) If the heat gun is used for welding, the pin around the integrated circuit can be blown by the heat gun. After the solder on the circuit board is melted, the heat gun is removed, and the pin is glued to the solder joint of the circuit board. If you use a soldering iron to weld, you can dip a small amount of solder on the head of the iron, and then drag it on a row of pins, and the solder will stick each pin to the solder joint of the circuit board. If some pins of the integrated circuit are short-circuited by the solder connection, you can use multiple strands of copper wire to absorb the excess solder, then apply rosin on the point, and heat it with an electric iron. The remaining solder between the pins will be automatically disconnected and returned to the pins.

(4) After welding, check whether there is short circuit or leakage welding between the pins of the integrated circuit. During the inspection, you can use a magnifying glass or a multimeter to detect. If there is leakage welding, apply a pointed soldering iron to repair welding, and finally clean up the rosin around the integrated circuit with anhydrous alcohol.