Take you to know the battery FPC again | Pay attention to these points!

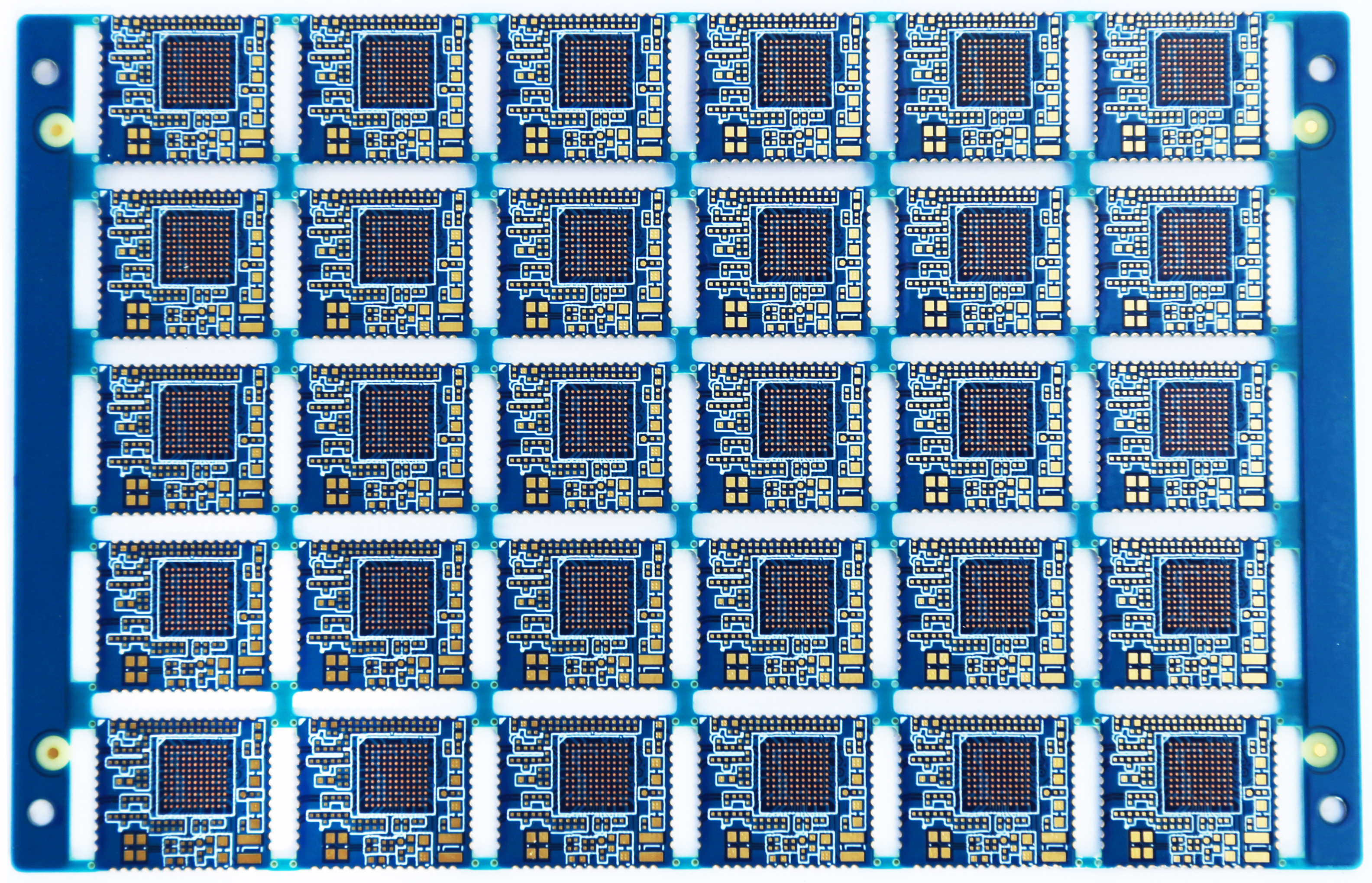

The circuit board manufacturer, circuit board designer and PCBA manufacturer will explain to you and show you a new understanding of battery FPC | Pay attention to these points!

The battery FPC is a flexible circuit board that can be folded and bent. It is generally used for the connection of the upper and lower parts of the flip phone, the battery protection circuit, etc. In order to ensure the flatness of the battery FPC, the manufacturer will generally flatten the battery FPC before shipment, and because the FPC is flexible, it is difficult to use vacuum packaging. Therefore, in the process of transmission and use, pay attention to ensure the flatness of FPC and try not to bend it.

2. Battery FPC is generally 1~2 layers, and multi-layer FPC is relatively rare. The base material and cover layer of FPC are generally polyimide, and the base material and copper foil are pressed and integrated. The thickness of some FPCs is indicated by the thickness of copper foil, such as 1.5OZ and 2.0OZ.

Unlike PCB, the opening of Cover Layer on copper foil is generally smaller than the area of copper foil, while the area of Solder Mask on PCB is generally larger than the area of copper foil. It should be noted that the FPC substrate and copper foil are bonded by resin. In some cases, the resin will overflow, causing pad contamination and solder skips.

3. The waste area (edge part without circuit) of FPC generally adopts two processes. One is called Solid Copper, which is covered with Copper foil as a whole. The other is Cross Hatching. The FPC flexibility of Solder Copper process is relatively small. It is flat without bending, but it is not easy to recover after bending. The FPC of Cross Hatching process is the opposite.

4. FPC needs to be supported in the whole SMT process. Generally, the support is made of synthetic materials that are not heat-resistant and anti-static. Some companies also use thin aluminum plates for support. The common positioning method is to stick FPC on the support plate with high-temperature tape.

However, it should be noted that the tape should be placed as far as possible in the middle of the four corners and the longer side of the FPC, which can prevent the FPC from cocking up. In addition, the thickness of the tape will have a certain impact on the solder paste printing. Therefore, the tape should not be pasted on the edge of the densely packed components and around the components with thin pins, especially on the bonding pad.

5. Because the flatness of battery FPC is relatively poor compared with PCB, and there are many factors such as support and adhesive tape, it is difficult for FPC to fully stick to the screen during the printing process, which will cause problems in the control of solder paste amount.

According to practical experience, there are two suggestions for screen plate opening: first, screen plate should narrow and lengthen the mesh as much as possible for IC components with tight pins, and the screen plate should be as thin as possible. Practice has proved that inverted trapezoidal mesh is more beneficial to printing. The other is to increase mesh as much as possible for chip components or connectors with large span to avoid missing welding due to uneven FPC.

6. Because the battery FPC needs to be supported, the profile setting of the reflow furnace must consider the heat absorption of the support plate during reflow welding. In general, it is recommended that the temperature under the reflow furnace be set a part higher than that above to ensure that the temperature of the support plate is close to that of the FPC to avoid cold welding. In addition, the cooling air at the outlet should be strong to ensure that the temperature of the support plate drops to a safe temperature, and cooling fans can be added at the outlet of the road.

7. In order to facilitate segmentation, the FPC and the edge are generally cut in advance along the contour. The uncut part generally retains a layer of substrate (Micro Joint) and needs to be punched with stamp holes. The stamp holes can not only facilitate segmentation but also prevent large burrs at the segmentation point.

The connection part can also ensure that the FPC will not tilt during SMT, so the Micro Joint should be reserved at each notch in the FPC. The cutting of FPC can be done manually or by using a special die similar to a punch press. The circuit board manufacturer, circuit board designer and PCBA manufacturer will explain to you and show you a new understanding of battery FPC | Pay attention to these points!