What are the factors affecting the characteristic impedance of FPC

PCB manufacturers, PCB designers and PCBA manufacturers will explain to you what factors affect the characteristic impedance of FPCs

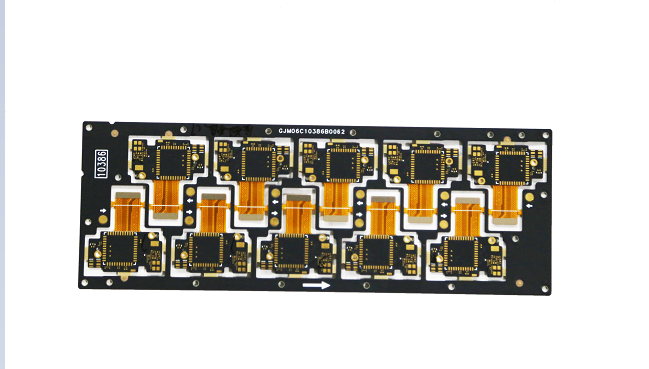

In general, the factors that affect the characteristic impedance of FPC are: dielectric thickness H, copper thickness T, wire width W, wire spacing, dielectric constant Er of the material selected for the stack, and the thickness of the solder mask.

In general, the greater the dielectric thickness and line spacing, the greater the impedance value; The larger the dielectric constant, copper thickness, wire width and solder resistance thickness, the smaller the impedance value. The relationship between these factors and the characteristic impedance is shown in Figure 1-20.

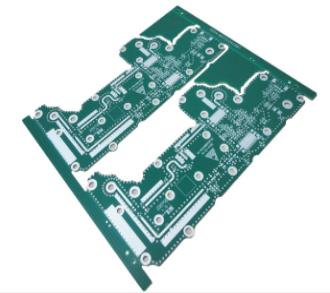

The first is the thickness of the medium. Increasing the thickness of the medium can improve the impedance, and decreasing the thickness of the medium can reduce the impedance; Different prepreg has different glue content and thickness. The thickness after pressing is related to the flatness of the press and the procedure of the pressing plate; For any kind of plate used, it is necessary to obtain the media layer thickness that can be produced, which is conducive to design and calculation. Engineering design, pressing plate control and incoming material tolerance are the key to media thickness control.

Second: Line width. Increasing the line width can reduce the impedance, and decreasing the line width can increase the impedance. The line width shall be controlled within a tolerance of+/- 10% to better meet the impedance control requirements. The notch of the signal line affects the entire test waveform. The single point impedance is too high to make the entire waveform uneven. The impedance line is not allowed to be patched, and the notch cannot exceed 10%. The line width is mainly controlled by etching control. In order to ensure the line width, process compensation shall be carried out for the engineering negative according to the etching side etching amount, photo drawing error and pattern transfer error to meet the line width requirements.

Third: copper thickness, reducing the line thickness can increase the impedance, and increasing the line thickness can reduce the impedance; The wire thickness can be controlled by pattern electroplating or selecting copper foil of corresponding thickness. The control of copper thickness is required to be uniform. Add shunt blocks to the plates of thin wires and isolated wires to balance the current and prevent the uneven copper thickness on the lines from affecting the uneven distribution of impedance on cs and ss surfaces. Cross the plates to achieve the goal of uniform copper thickness on both sides.

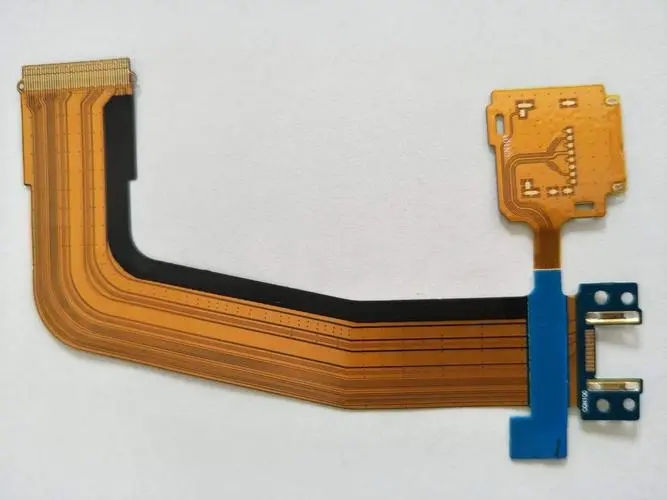

Fourth: dielectric constant. Increasing dielectric constant can reduce impedance, and decreasing dielectric constant can increase impedance. The dielectric constant is mainly controlled by materials. The dielectric constant of different plates is different, which is related to the resin material used: the FPC team learned that the dielectric constant of FR4 plate is 3.9-4.5, which will decrease with the increase of the frequency used. The dielectric constant of PTFE plate is 2.2-3.9. To obtain high signal transmission, high impedance value is required, so low dielectric constant is required.

The fifth is the thickness of solder mask. Printing solder mask will reduce the outer layer impedance. Under normal circumstances, printing once for resistance welding can reduce the single end by 2 ohms and the differential by 8 ohms. The reduction value of printing twice is twice that of printing once. When printing more than three times, the impedance value will not change. PCB manufacturers, PCB designers, and PCBA manufacturers will explain to you what factors affect the characteristic impedance of FPCs.