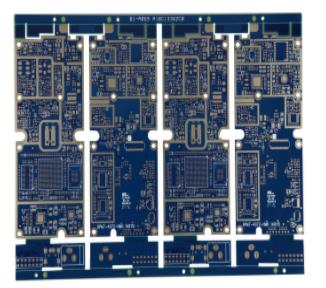

Blackening and Limit Temperature Test of Electroplated Gold Layer on Printed Circuit Board

PCB manufacturer, PCB designer and PCBA processor will explain the blackening and limit temperature test of electroplated gold layer on PCB

Blackening of the electroplated gold layer often occurs when copying automobile circuit board, which affects the quality and performance of the circuit board. So, what are the reasons for the blackening of the electroplated gold layer on the printed circuit board?

1. Thickness control of electroplated nickel layer

The electroplated gold layer of automobile circuit board is generally very thin, which is reflected on the electroplated gold surface, many of which are caused by the poor performance of electroplated nickel. Generally, the thin nickel plating layer will cause the product appearance to be white and black. Generally, the thickness of nickel layer should be about 5UM.

2. Liquid medicine condition of nickel plating cylinder

If the liquid medicine of nickel cylinder is not well maintained for a long time and carbon treatment is not carried out in time, the nickel layer after electroplating will be easy to produce lamellar crystals, and the hardness and brittleness of the coating will increase. If it is serious, the problem of blackening coating will occur. Therefore, it is necessary to carefully check the liquid medicine condition of the production line of the circuit board factory, make comparative analysis, and carry out thorough carbon treatment in time to restore the activity of the liquid medicine and clean the electroplating solution.

3. Metal cylinder control

As long as the liquid medicine is filtered and replenished well, the gold cylinder will be more polluted and stable than the nickel cylinder. However, it is necessary to pay attention to check whether the gold cylinder supplement is sufficient and excessive, how the liquid medicine PH value is controlled, and how the conductive salt is in good condition. If there is no problem, use AA machine to analyze the impurity content in the solution. The state of the liquid medicine in the margin tank. Finally, check whether the gold cylinder filter cotton core has not been replaced for a long time.

These are the reasons for the blackening of the electroplated gold layer on the printed circuit board. I hope it will be helpful to you.

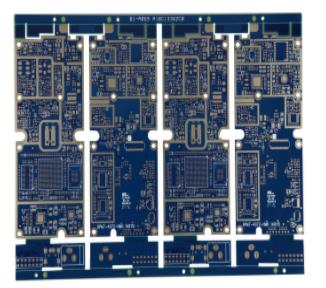

How to test the limit temperature of 5G PCB?

In the process of 5G PCB fabrication, because the 5G PCB assembly board printed with solder paste and not welded cannot fix the test end of the thermocouple, it is necessary to use the actual welded product for temperature test. How to test the limit temperature of 5G PCB?

1、 Selection of test points: according to the complexity of the 5G PCB assembly board and the number of channels of the collector, select at least three representative temperature test points that can reflect the high, medium and low temperature of the 5G PCB surface assembly board.

2、 Fixed thermocouple: weld the test ends of multiple thermocouples to the test points (solder joints) with high-temperature solder, and remove the solder on the original solder joints before welding; Or use high temperature adhesive tape to stick the test ends of thermocouples on each temperature test point of 5G PCB.

3、 Insert the other end of the thermocouple into 1, 2, 3... of the machine table. The position of the jack or the socket of the collector shall be inserted, and the polarity shall not be reversed.

4、 Place the 5G PCB assembly board on the surface to be tested on the conveyor chain/mesh belt at the inlet of the reflow welder, and then start the KIC temperature curve test program.

5、 With the 5G circuit board running, draw a real-time curve on the screen (when the device has its own KIC test software).

6、 When the 5G circuit board runs past the cooling area, pull the thermocouple wire to pull the 5G circuit board assembly board back. At this time, a test process is completed, and the complete temperature curve and peak temperature/schedule are displayed on the screen.

The above is about how to test the limit temperature of 5G PCB. I hope it can help you. PCB manufacturers, PCB designers and PCBA processors will explain the blackening and limit temperature test of the electroplated gold layer on PCB.