What is design for manufacturability of pcb flexible circuit board?

PCB manufacturing, PCB design and PCBA processing manufacturers explain to you what is manufacturability design of flexible PCB?

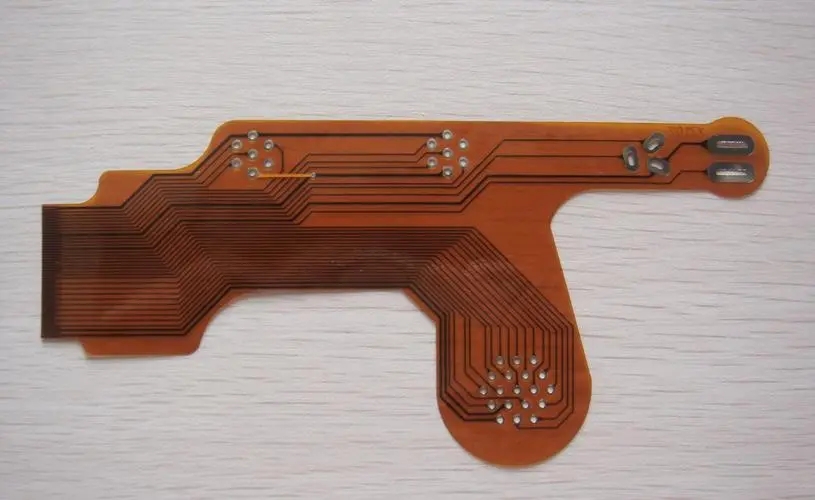

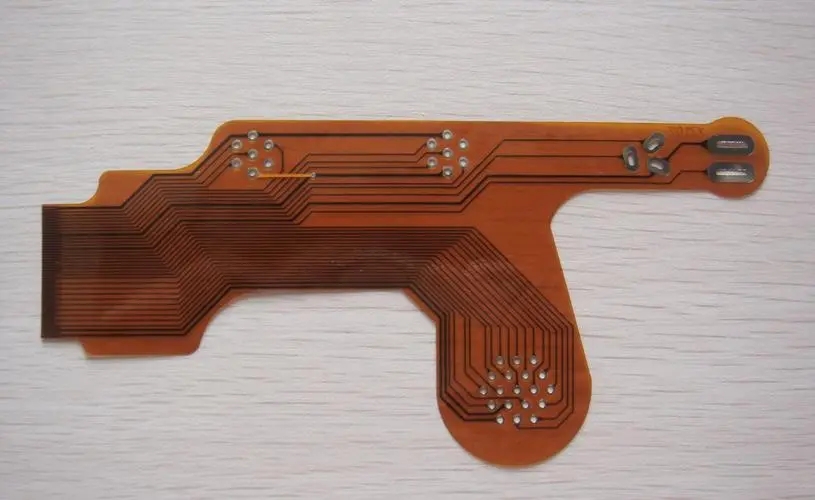

Flexible Printed Circuit (FPC), also known as flexible circuit board and flexible circuit board, is favored for its light weight, thin thickness, free bending and folding and other excellent characteristics. However, the quality inspection of FPC in China mainly depends on manual visual inspection, with high cost and low efficiency. With the rapid development of the electronic industry, the circuit board design tends to be more and more high-precision and high-density, and the traditional manual detection methods can no longer meet the production needs. Automatic detection of FPC defects has become an inevitable trend of industrial development.

Flexible Printed Circuit (FPC) is a highly reliable and excellent Flexible printed circuit board made of polyimide or polyester film. It has the characteristics of high wiring density, light weight, thin thickness and good bending performance.

What is DFM?

Design for m patch nuf patch ctur patch reliability, that is, consider the manufacturability of products from the beginning of design, improve the pass through rate and reliability of products, make products easier to manufacture and reduce manufacturing costs.

Design for manufacturability is based on the idea of concurrent design. In the design stage of products, the process requirements, test requirements and assembly rationality in the manufacturing process are comprehensively considered, and the cost, performance and quality of products are controlled by means of design.

Generally speaking, design for manufacturability mainly includes three aspects: manufacturability design of flexible circuit board, mountability design of flexible circuit board, and low manufacturing cost design.

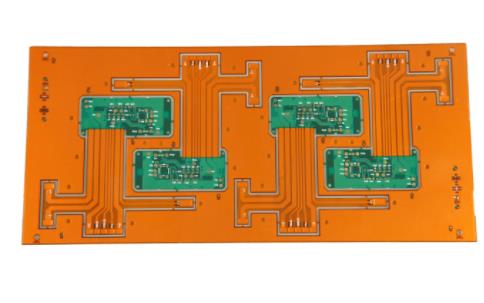

The design for manufacturability of flexible circuit board (FPC) is mainly from the perspective of flexible circuit board manufacturing, considering the manufacturing process parameters, so as to improve the pass rate of board making and reduce the process communication cost. For example, whether the line width and line spacing are designed sufficiently, whether they can meet the actual requirements of the factory, and whether the distance between holes to lines and between holes is in compliance, these points should be considered clearly in the design.

The assemblability design of flexible circuit board (FPC) is to consider how to standardize the layout, how to correctly design the flexible circuit board packaging, and how to balance the heat dissipation of components from the perspective of FPC assembly and processing. The standard layout generally considers that the distance between devices should not be too close, and spatial interference should not occur. Flexible circuit board packaging is mainly based on the consideration of soldering performance. The bonding pads of components and flexible circuit boards need to be matched, as well as the consideration of whether the device pins have enough tin climbing allowance.

Low manufacturing cost is also very important. The market competitiveness of a product depends on its cost. Based on the cost, two aspects should be considered. First, when choosing the manufacturing process, the designer should try to be optimal and simple; The second is to master the quotation rules of the board factory. Each board factory has its own set of quotation logic. Maybe the quotation rules of the board factory are biased, but most of them are similar.

To sum up, it is not difficult to find that design engineers need to consider a lot of things. A company that is slightly strict may have dozens or hundreds of design rules. If they do not use tools and are controlled manually, the probability of error is high. However, there are not many tools and software for process inspection in the current market. A few commercial software are sold at a high price, which is difficult for many small and medium-sized enterprises to bear.

PCB manufacturers, PCB designers and PCBA manufacturers will explain to you what is manufacturability design of flexible PCB?.