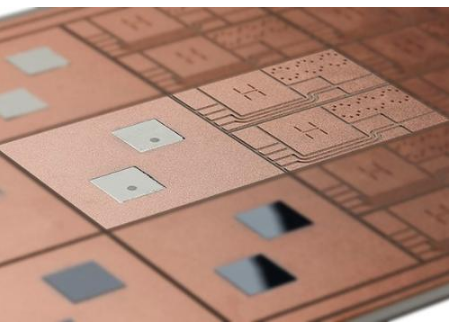

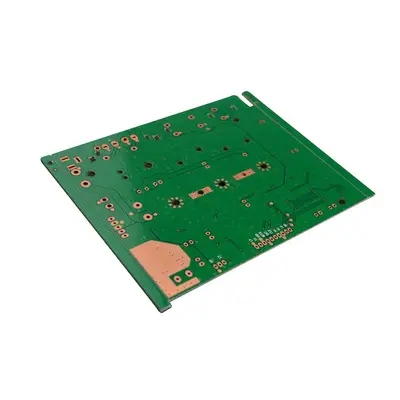

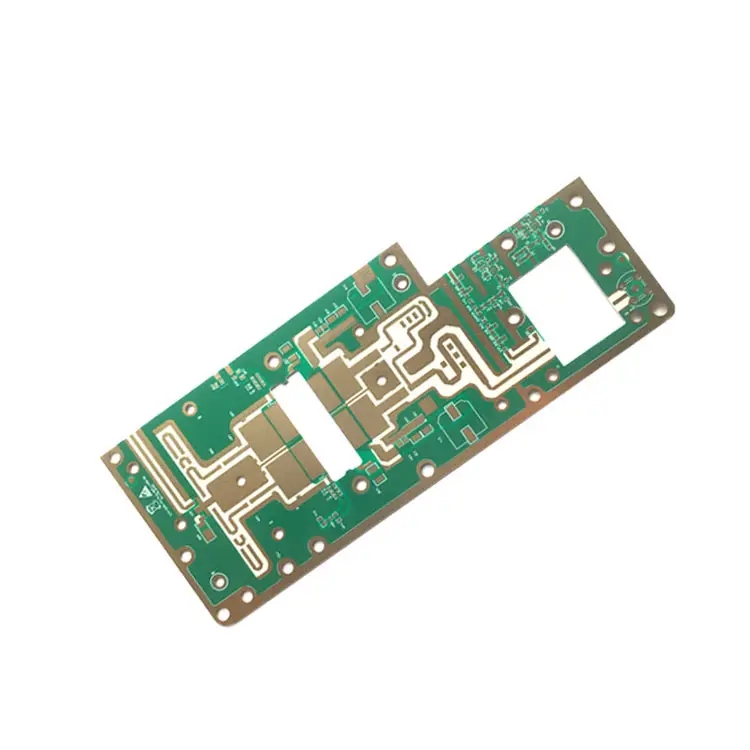

Electronic engineer explains PCB maintenance methods of circuit board factory

The circuit board manufacturer, circuit board designer and PCBA manufacturer explain to you the PCB maintenance methods of the circuit board factory by the electronic engineer

The first step for a circuit board factory to repair a PCB is to observe whether the circuit board has been artificially damaged, mainly from the following aspects:

① Check whether the circuit board has been dropped, resulting in the deformation of the board corner, or the chip on the board has been deformed or damaged.

② Observe the socket of the chip to see if it is forced to be broken due to lack of special tools.

③ Observe the chip on the circuit board. If there is a socket, first observe whether the chip is inserted incorrectly. This is mainly to prevent the operator from inserting the chip in the wrong position or direction when repairing the circuit board. If the error is not corrected in time, when the circuit board is powered on, the chip may be burned, causing unnecessary losses.

④ If there are short circuit terminals on the circuit board, observe whether the short circuit terminals are inserted incorrectly.

The maintenance of the circuit board requires a solid theoretical foundation and careful work. Through careful observation by the maintainer, the cause of the problem can sometimes be determined at this step.

The second step is to observe whether the components on the circuit board are burned. For example, whether the resistance, capacitor and diode are blackened or blurred. Under normal circumstances, even if the resistance is burnt, its resistance value will not change, its performance will not change, and normal use will not be affected. At this time, a multimeter is required to assist in measurement. However, if capacitors and diodes are burnt, their performance will change, and they will not play their due role in the circuit, which will affect the normal operation of the entire circuit. At this time, new components must be replaced.

The third step is to observe whether the integrated circuits on the circuit board, such as 74 series, CPU, coprocessor, AD and other chips, are bulged, cracked, burnt and blackened. If this happens, it is almost certain that the chip has been burned out and must be replaced.

The fourth step is to observe whether the wiring on the circuit board has peeling, burning and open circuit. Whether the copper sink hole is separated from the bonding pad.

Step 5: Observe the fuse on the circuit board (including the fuse tube and thermistor) to see if the fuse is blown. Sometimes, because the fuse is too thin to see clearly, you can use an auxiliary tool - multimeter to judge whether the fuse tube is damaged.

The above four situations are the methods used by the circuit board factory to repair PCB boards, which are basically caused by excessive current in the circuit. However, the specific cause of excessive current requires specific analysis. However, the general idea of finding problems is to first carefully analyze the schematic diagram of the circuit board, and then find its superior circuit according to the circuit of the burned components, and deduce it step by step. Then, based on some experience accumulated in the work, analyze the place most prone to problems and find out the cause of the failure. The circuit board manufacturer, circuit board designer and PCBA manufacturer will explain the PCB maintenance methods of the circuit board factory to the electronic engineers.