Electronic engineer: explain the defects of PCB electroplating pure tin

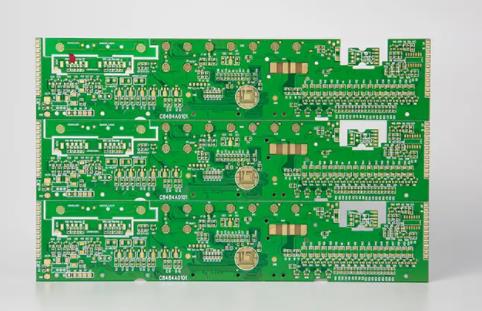

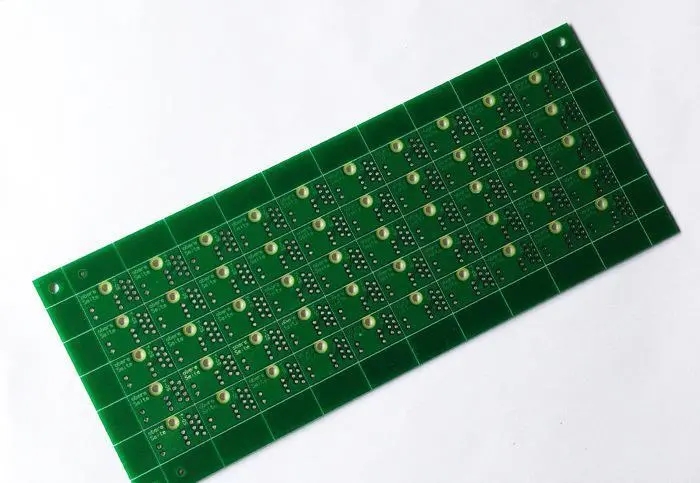

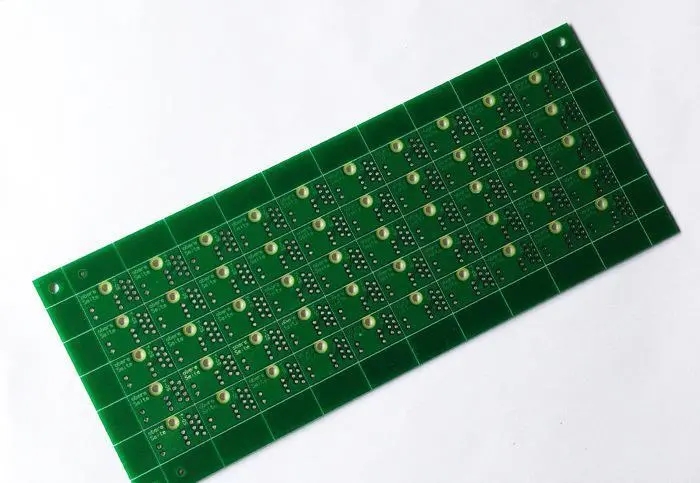

Circuit board manufacturing, circuit board design and PCBA processing manufacturers explain to you the defects of PCB electroplating pure tin

1、 Preface

In the manufacturing process of PCB, most manufacturers still use the wet film process for imaging due to cost considerations, which will inevitably cause problems such as "infiltration, bright edges (thin tin)" when electroplating pure tin on graphics. In view of this, solutions to common problems in pure tin plating process summarized over the years will be discussed with you. Among them, the electroplating process of PCB can be roughly classified into acid bright copper electroplating, nickel/gold electroplating, and tin electroplating. This article introduces the technology, process flow, and specific operation methods of electroplating process in PCB processing.

technological process:

Pickling → full plate copper electroplating → pattern transfer → acid degreasing → secondary countercurrent rinsing → micro etching → secondary countercurrent rinsing → pickling → tin plating → secondary countercurrent rinsing → countercurrent rinsing → pickling → pattern copper electroplating → secondary countercurrent rinsing → nickel plating → secondary water washing → citric acid leaching → gold plating → recycling → 2-3 pure water washing → drying

2、 Analysis of the causes of "infiltration plating" on wet film plate (quality problem of non pure tin solution)

1. The copper surface brushed before silk screen printing must be clean to ensure good adhesion between the copper surface and wet oil film.

2. When the exposure energy of wet film is low, the wet film will not be fully cured, and the ability to resist electroplating pure tin will be poor.

3. The wet film pre baking parameters are unreasonable, and the local temperature difference of the oven is large. As the thermal curing process of photosensitive materials is sensitive to temperature, low temperature will lead to incomplete thermal curing, thus reducing the ability of wet film to resist electroplating of pure tin.

4. The ability to resist electroplating pure tin is reduced without post local/curing treatment.

5. The plates from electroplating pure tin must be thoroughly cleaned with water. At the same time, each plate must be inserted into a shelf or a dry plate. No stacking is allowed.

6. Wet film quality problem.

7. Impact of production and storage environment and time. Poor storage environment or long storage time will cause the wet film to expand, reducing its ability to resist electroplating pure tin.

8. The wet film is dissolved in the tin cylinder under the attack of pure tin polish and other organic pollution. When the anode area of the tin plating bath is insufficient, it will inevitably lead to the reduction of current efficiency and oxygen evolution in the electroplating process (electroplating principle: oxygen evolution in the anode, hydrogen evolution in the cathode). If the current density is too high and the sulfuric acid content is too high, the cathodic hydrogen evolution will attack the wet film, which will lead to the occurrence of tin infiltration (the so-called "infiltration").

9. High concentration of the stripping solution (sodium hydroxide solution), high temperature or long immersion time will produce tin flow or dissolution (the so-called "infiltration").

10. The current density of pure tin plating is too high. Generally, the best current density of wet film quality is 1.0~2.0A/dm2. If the current density is beyond the range, some wet film quality is easy to produce "infiltration".

3、 Causes of "Impregnation" Caused by Solution Problems and Improvement Measures

1. Reasons:

The production of "infiltration plating" caused by the problem of liquid medicine mainly depends on the formula of pure tin polish. The penetrant penetration is strong, and the attack on the wet film in the electroplating process produces "infiltration". That is, when the pure tin polish is added too much or the current is slightly too large, the "penetration" will occur. Under normal current operation, the "penetration" is related to the poor control of the liquid medicine operation conditions. For example, when the pure tin polish is added too much, the current is too large, and the content of stannous sulfate or sulfuric acid is too high, these will accelerate the attack on the wet film.

2. Improvement countermeasures:

The performance of most pure tin polishers determines that they are more aggressive to wet film under the action of current. In order to avoid reducing the "penetration" of wet film coated pure tin plate, it is recommended that three things should be done to produce wet film coated pure tin plate:

①。 The addition of pure tin polish must be monitored in a small amount for many times, and the content of pure tin polish in the plating solution usually needs to control the lower limit;

②。 The current density shall be controlled within the allowable range;

③。 The control of liquid medicine composition, such as stannous sulfate and sulfuric acid content at the lower limit, will also be beneficial to the improvement of "infiltration plating".

4、 Characteristics of market pure tin polish

1. Some pure tin polish is limited to current density and its operating range is relatively narrow. This pure tin polish is usually easy to produce wet film "infiltration", and its allowable standard range for stannous sulfate, sulfuric acid and current density is relatively narrow;

2. Some pure tin polishers are applicable to a wide range of current density operations. Such pure tin polishers are usually not easy to produce wet film "infiltration", and their allowable standard ranges for stannous sulfate, sulfuric acid and current density are relatively wide;

3. Some pure tin polish agents are prone to "missing plating, infiltrating plating, blackening" or even "brightening" of the line edge on the wet film;

4. Some pure tin polish agents do not produce the problem of "brightening" of the line edge on the wet film (no baking or UV curing treatment), but there is still the problem of "infiltration plating", which can be improved by baking or UV curing treatment. Before the wet film plate pure tin plating process, there are no problems such as "brightening and infiltration" of the line edge without baking or UV curing treatment. At present, there are really few such pure tin polish agents on the market.

The specific operation shall strictly control the operating current density, temperature, anode area, stannous sulfate, sulfuric acid and the content of tin polish according to the characteristics of pure tin polish provided by different liquid medicine suppliers.

5、 Causes of "Bright" Line Edge in Wet Film Plate Plating Pure Tin

As the formula of pure tin polish generally contains organic solvent, while the wet oil film itself is composed of organic solvent and other materials, the two are incompatible, especially reflecting the "shine" at the edge of the line.

Factors related to the "brightening" of line edges:

1. Pure tin polish (generally, the formula will contain organic solvent);

2. The current density is low (the lower the current density is, the more likely the line edge will "shine");

3. The baking board conditions are inconsistent (the baking board is mainly used to volatilize the organic solvent in the wet oil film);

4. The thickness of wet oil film of silk screen is uneven (the thicker the oil film is, the easier it is to "shine");

5. Quality problem of wet oil film itself (choose wet oil film to match pure tin plating solution);

6. Quality of acid degreaser for pretreatment (selecting a good acid degreaser not only enhances the water washability of the solution, but also greatly reduces the probability of residue on the copper surface after oil removal);

7. Excessive tin polish in the plating solution (excessive tin polish will cause organic pollution in the plating solution. In order to prevent the wet film tin plating plate from polluting the tin cylinder with the increase of production capacity, 8-hour carbon core filtration is conducted every half month, and 5ASF, 10ASF and 15ASF current densities are used for electrolysis for 5 hours, 2.5 hours and 0.5 hours respectively every week);

8. Temperature related (the higher the temperature is, the more uneven the displacement in the low potential area is. The test proves that the higher the temperature is, the more likely the line edge will "shine". In addition, the higher the temperature is, the faster the oxidation of Sn2+and the consumption of additives will be.);

9. Poor conductivity (poor conductivity directly causes the current density to be seriously low, and when the current density is lower than 10 ASF, the line edge is most likely to "shine").

10. The wet film plate has a long storage time (the wet film plated pure tin plate should be stored in a workshop with relatively good environment, and the storage time should not exceed 72 hours. The graphic electroplating process staff should take the plate according to the production situation, but the storage time in the electroplating workshop should preferably not exceed 12 hours);

11. The anode area of the pure tin plating bath is insufficient (insufficient anode area of the tin plating bath will inevitably lead to lower current efficiency and oxygen evolution during electroplating. The ratio of anode area to cathode area is generally 2~3:1, and the standard anode spacing of the pure tin bath is about 5cm, so as to ensure sufficient anode area).

Therefore, some bad problems are actually caused by the inconspicuous details of a process. As long as you consider them from multiple perspectives, you can find the key to the problem and solve it.

6、 Grasp the advantages and disadvantages of wet film quality in the market

The good quality of wet film is very beneficial to reduce the "brightness" of the line edge, but it cannot be completely eliminated. In addition, the oil film that is more suitable for making pure tin plate is not necessarily a good oil film. Here is a brief introduction to the quality characteristics of the wet film:

1. A good wet film is not easy to produce "infiltration", and the oil film is not easy to be broken down and it is relatively easy to remove the film when the current resistance density is high;

2. Some wet films may indeed play a role in reducing the "brightening" problem at the line edge, but it is relatively difficult to remove the film. This kind of wet oil film is not suitable for liquid medicine with a wide range of current density operations. Slightly high current density is likely to cause problems such as "infiltration, film clamping, blackening" and even breakdown of the oil film.

About Electrotinning

① Purpose and function: Pure tin is mainly used as the metal anti-corrosive layer to protect the circuit etching;

② The bath solution is mainly composed of stannous sulfate, sulfuric acid and additives; The stannous sulfate content shall be controlled at about 35g/L, and the sulfuric acid content shall be controlled at about 10%; Tin plating additives are generally added according to the method of kiloampere hours or according to the actual production board effect; The current of tin electroplating is generally calculated as 1. 5 A/square decimeter times the electroplating area on the plate; The temperature of the tin cylinder is maintained at room temperature. Generally, the temperature does not exceed 30 degrees, and most of it is controlled at 22 degrees. Therefore, it is recommended to install a cooling temperature control system for the tin cylinder in summer because of the high temperature;

③ Process maintenance: timely supplement tin plating additives according to kiloampere hours every day; Check whether the filter pump works normally and whether there is air leakage; Wipe the cathode conducting rod with a clean wet rag every 2-3 hours; Regularly analyze stannous sulfate (once/week) and sulfuric acid (once/week) in tin cylinder every week, adjust tin plating additive content through Hall cell test, and timely supplement relevant raw materials; Clean the anode conducting rod and electric joints at both ends of the tank every week; Use low current 0 every week. 2? 0 5ASD electrolysis 6? 8 hours; Check whether the anode bag is damaged every month, and replace the damaged bag in time; Check whether there is anode mud at the bottom of the anode bag, and clean it in time if there is; Continuous filtering with carbon core for 6? Every month? 8 hours, and low current electrolysis for impurity removal; Determine whether to require major treatment (activated carbon powder) according to the pollution condition of the tank liquid every half a year or so; Replace the filter element of the filter pump every two weeks;

④ Large processing program: A Take out the anode, take down the anode bag, clean the anode surface with a copper brush, wash it dry, put it into the anode bag, and put it into the acid tank for standby B Immerse the anode bag in 10% alkali solution for 6? 8 hours, wash and rinse dry, then soak in 5% dilute sulfuric acid, wash and rinse dry for standby; C. Transfer the tank solution to the standby tank, and press 3 ° C? 5g/L slowly dissolve the activated carbon powder into the bath solution. After the solution is completely dissolved, adsorb it for 4-6 hours. Use 10um PP filter element plus filter aid to filter the bath solution into the cleaned working tank, place the anode, hang it into the electrolytic plate, and press 0. 2-0。 5ASD current density low current electrolysis 6? 8 hours, D After chemical analysis, adjust the content of sulfuric acid and stannous sulfate in the tank to the normal operating range; Add tin plating additives according to the results of Hall cell test; E. Stop electrolysis when the color of the electrolytic plate is uniform; F. Trial plating OK;

⑤ When replenishing drugs, such as stannous sulfate and sulfuric acid, when the added amount is large; Low current electrolysis shall be conducted after adding; Attention shall be paid to safety when adding sulfuric acid. When adding large amount of sulfuric acid (more than 10 liters), it shall be added slowly in several times; Otherwise, the temperature of the bath solution will be too high, and the stannous oxide will be oxidized, speeding up the aging of the bath solution;

⑥ Drug addition calculation formula:

Stannous sulfate (unit: kg)=(40-X) × Tank volume (L)/1000

Sulphuric acid (unit: liter)=(10% - X) g/L × Tank volume (L)

Or (in liters)=(180-X) g/L × Tank volume (L)/1840

Circuit board manufacturing, circuit board design and PCBA processing manufacturers explain to you the defects of PCB electroplating pure tin.