Probe into the causes of process problems caused by PCB pretreatment

PCB manufacturers, PCB designers and PCBA manufacturers explain and analyze the causes of PCB pre-processing problems

The PCB pretreatment process largely affects the smooth progress of the manufacturing process and the quality of the manufacturing process. This paper makes some analysis on the problems that may be caused by human, machine, material and other conditions in the PCB pretreatment program to achieve more effective operation.

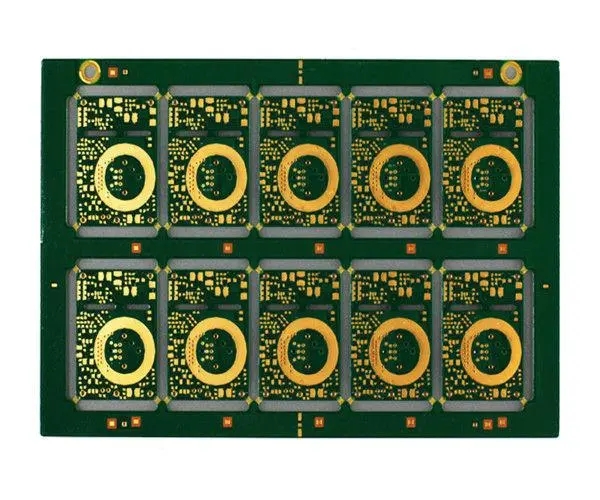

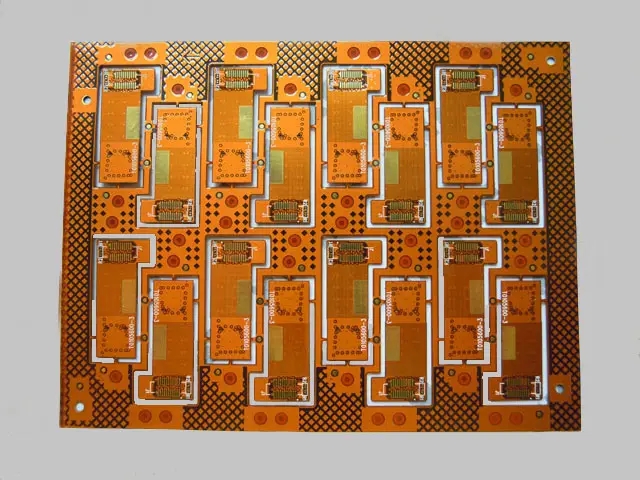

Be able to use the process of pretreatment equipment, such as: inner pretreatment line, electroplating copper pretreatment line, D/F, anti welding (resistance welding), etc.

2. Take the hard board PCB anti soldering (solder mask) pre-treatment line as an example (different manufacturers have differences): brushing * 2 groups ->water washing ->acid washing ->water washing ->cold air knife ->drying section ->sun tray plate collection ->discharging plate collection.

3. Generally, # 600 and # 800 alloy steel brushes are used, which will affect the roughness of the board surface and thus the adhesion between the ink and the copper surface. However, if the brush wheel is used for a long time, if the products are not placed on both sides, it is easy to produce dog bones, which will lead to uneven coarsening of the board surface, even line deformation, and different color difference between the printed copper surface and INK, so the whole brush operation is required. Before the brushing and grinding operation, the brush mark test shall be conducted (water breaking test shall be added in case of D/F), and the width of the brush mark shall be measured to be about 0. 8~1。 2mm, depending on different products. After updating the brush, the level of the brush wheel needs to be corrected, and lubricating oil needs to be applied regularly. If no water is boiled during brushing and grinding, or the spraying pressure is too small to form a fan-shaped angle, copper powder is likely to occur. Slight copper powder may cause micro short circuit (dense line area) or unqualified high-voltage test during finished product testing.

Another problem that is easy to occur in pre-treatment is the oxidation of the board surface, which will lead to bubbles on the board surface or bubbles after H/A.

The position of the solid water retaining roller of the pretreatment is wrong, which causes excessive acid to be brought into the water washing section. If the number of water washing tanks in the rear section is insufficient or the injected water is insufficient, the acid will remain on the board surface.

2. The poor water quality or impurities in the water washing section will also cause the adhesion of foreign matters on the copper surface.

3. If the suction roller is dry or saturated with water, it will not be able to effectively take away the water on the product to be manufactured, which will cause excessive residual water on the board and in the hole, and the subsequent air knife will not be able to fully play its role. At this time, most of the resulting cavitation will be at the edge of the through hole, in a teary state.

4. When the temperature of the plate is still surplus during discharging, the plate will be folded, which will oxidize the copper surface inside the plate.

In general, PH detector can be used to monitor the PH value of water, and infrared ray can be used to measure the residual temperature of plate surface discharging. A solar plate collector is installed between discharging and stacking plate collecting to cool the plate. The wetting of water absorbing roller needs to be specified. It is better to have two groups of water absorbing rollers for alternate cleaning. The angle of the air knife needs to be confirmed before daily operation, and pay attention to whether the air duct in the drying section has fallen off or been damaged. PCB manufacturers, PCB designers and PCBA manufacturers will explain and analyze the causes of manufacturing process problems caused by PCB pre-processing.