Operation Guide for PCBA Circuit Board Cleaning

Solder PCBA components used need welding materials to be welded to the circuit board to ensure the welding quality After welding, the welding material remains on the surface of the circuit board, forming dirt, which affects the appearance and power efficiency

The surface must be cleaned with washer water; Provide correct guidance and protection for operators to shuffle cards, ensure that customers' requirements are met after shuffling, and reduce customer complaints and employee injuries;

PCBA cleaning operation;

Applicable to cleaning station and cleaning after maintenance;

4.1 Tools and data used in this process

51. Preparation before operation

5.1.1 Each shift shall enter the workshop/post 10 minutes in advance to participate in the morning and evening party, and conduct self inspection on the requirements of the meeting management personnel, work arrangements and problems in the work;

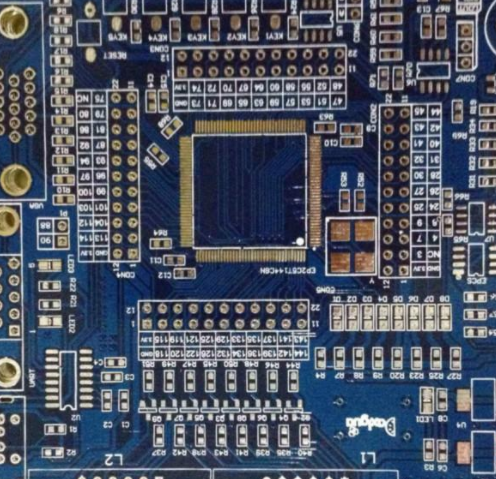

Circuit board

5.1.2 On the job, the personnel on duty shall hand over the "Handover Record Form" and the problem points in the face-to-face inspection, as well as the handover instructions for the online inspection of product status and identification, to clarify the inspection work;

5.1.3 According to the requirements of job responsibilities, clean the PCBA plate after the welding is qualified, and pay special attention to the cleaning methods of each component;

5.1.4 In the process of going to work, record the problems in the process at any time, especially the problems and exceptions that need to be understood and coordinated, so as to follow up in the next shift; One hour before going off duty, put them in the "After shift Handover Record Form";

5.1.5 Wear masks, gloves and electrostatic rings before starting work;

5.2 Operation process and method

5.2.1 Manual+brush cleaning method:

5.2.1.1 Pick up the PCB to be cleaned with one hand and place it on the workbench (when placing the PCB, make it an angle of 45 to 60 degrees with the workbench, so that the cleaning sewage can be discharged from the PCB after cleaning the PCB), and then dip it again with one hand

Tilt the anti-static brush with washing water from top to bottom, scrub in the same direction, and scrub repeatedly until the residual tin slag and flux on the PCB are cleaned;

"5.2.1.2 After cleaning, check whether there are residues and stains on the PCB board. If there are residues on the surface, use a dust-free cloth to wipe point-to-point. After confirming that there are no problems, place the PCB board on the electrostatic board orderly;

5.2.1.2 After the operation, place the washing water and anti-static brush at the designated position, and make a "5S" workstation;

5.2.2 Cleaning method of the scrubber:

5.2.2.1 Before washing dishes, make sure that the dishes to be washed can be washed in this way, connect the power supply, and wear a mask for personal protection. When the washing machine is turned on, the power switch on the brush surface rotates;

5.2.2.2 Put the plate into the sponge soaked in the washing water, and dirty it with the washing water to decompose the dirt on the plate;

5.2.2.3 Hold the plate soaked in the water of the washing machine firmly, place it on the washing machine for about 3 seconds, pick up the plate and turn it over to check whether there is a flow that meets the cleaning requirements at the next station, otherwise, repeat steps 2 and 3 again

When brushing the board, special attention must be paid to holding the board firmly to ensure that the board will not be broken due to flying hands during brushing;

5.2.2.4 At the end of work or after work, please cover the washing water with glass plate to reduce volatilization.

5.3 Precautions for board washing:

5.3.1 When cleaning the circuit board, do not clean the speakers, buzzers, sensors, display screens, relays, switches, gold fingers, sockets and other connectors on the circuit board to avoid damage to the equipment caused by the cleaning water;

5.3.2 The surface marking of electrolytic capacitor. When the circuit board is cleaned, the communication module and other components on the circuit board will be cleaned Avoid identification caused by tooth brushing;

"5.3.3 If dirt is found on the anti-static brush during operation, it shall be cleaned in time before use;

"5.3.4 Check whether there is residual tin slag and flux at IC and other welding positions on PCB;

5.3.5 If the anti-static brush is found to be depilated or has insufficient hardness, it shall be replaced in time;

5.3.6 In the process of cleaning the circuit board, it is prohibited to use electrostatic tweezers to pick up a dust-free cloth to wipe, so as to prevent the front end of the tweezers from damaging the chip components and causing artificial defects;

5.3.7 After that, PCBA products have been cleaned. Self inspection confirms whether the barcode and silk screen of the products have been erased and blurred, and it is found that the products are considered defective

5.3.8 Washing water is flammable and corrosive. Workers shall wear masks for protection and pay attention to safety