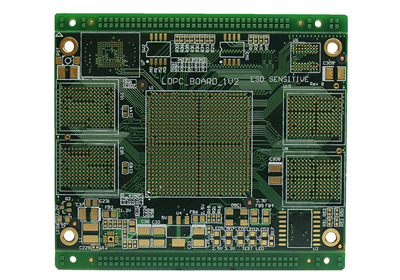

Pcb circuit board test mode and fixture problem explanation

Automatic test or manual test?

As the output and speed of each production line increase (one of the main ways to achieve economies of scale is to improve the productivity of each pcb test equipment), it should be considered whether to automate the test process. In fact, the automatic function test saves the time of loading/unloading, and does not need to add other test systems. When considering increasing the output, the increased cost of transportation equipment is usually ignored.

The disadvantages of test automation include an initial hardware investment, the time to integrate with the production line, whether the test system can keep pace with the speed of the production line, and the problems caused by equipment failure. The offline tester will not directly affect the assembly line. If the tester fails, the product can be taken out of the pcb production line and put aside to continue production, so that the production line will not be affected. However, processing time and labor are also problems.

It should be remembered that manual testing usually requires several cables and connectors to connect the UUT. Compared with the probe on the needle bed clamp, these cables have a lower service life. Therefore, they should be included in the maintenance plan, which can reduce the intermittent failure.

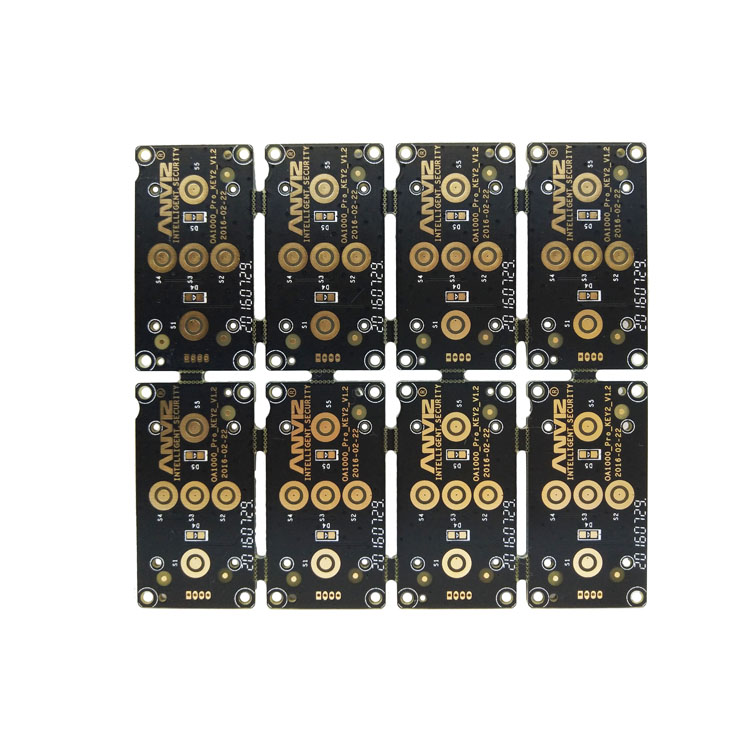

Fixture problems

Due to different production lines, workshops and labor rates, fixtures can range from simple plywood with pins and connecting cables to complex full-automatic needle bed test fixtures connected by conveyor belts to assembly lines. Obviously, these factors indicate that there is no fixed plan.

A double-sided clamp is loaded manually, a ribbon cable is connected to the main I/O connector, and the probe installed on the top can contact the key test points on the UUT. This is the ideal design required by a medium-sized factory. The operator must connect the ribbon cable, close the roof and then start the test. Manual exploration is not needed here for calibration and diagnosis, because the roof can contact all relevant areas. Ribbon cables and roof probe connections should be designed to be easily replaced because these cables are often bent and worn.

When dealing with fixture suppliers, we should remember these problems and also think about where the products will be manufactured, which is a place that many test engineers will ignore. For example, we assume that the test engineer is in California, the United States, while the product is manufactured in Thailand. Test engineers will think that the products need expensive automatic jigs, because the plant price in California is high, and the number of testers is required to be as few as possible, and automatic jigs are also used to reduce the employment of high-tech and high wage operators. However, in Thailand, these two problems do not exist. It is cheaper to solve these problems manually, because the labor cost here is very low and the land price is also very cheap. Large factories are not a problem. Therefore, sometimes first-class equipment may not be popular in some countries.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the calibration circuit and fault diagnosis in the functional test of pcb PCB.