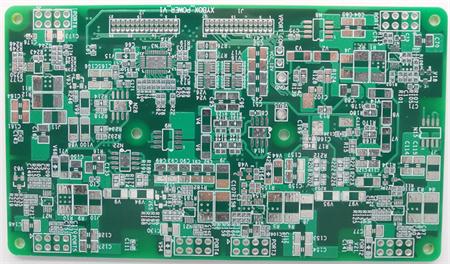

What are the requirements for the card boards used for PCB boards in SMT workshops?

Circuit board manufacturing, circuit board design, PCBA processing manufacturers will explain to you what are the requirements for the card boards used for PCB boards in SMT workshops

During PCB processing in SMT workshop, in order to protect PCB from electrostatic hazards, PCB pallet or PCB card will be used for placement. The full name of card board is anti-static card board, which is mainly used to reduce the damage of PCB board due to vibration during transportation and reduce the damage rate. The groove design in the tray saves space and also strengthens the fastening between the trays.

During PCB processing in SMT workshop, in order to protect PCB from electrostatic hazards, PCB pallet or PCB card will be used for placement. The full name of card board is anti-static card board, which is mainly used to reduce the damage of PCB board due to vibration during transportation and reduce the damage rate. The groove design in the tray saves space and also strengthens the fastening between the trays. Greatly reduce the occurrence rate of defective products, improve work efficiency, and better improve the production process.

Requirements for card boards used for PCB boards in SMT workshop

1) The anti-static performance of PCB card tray, anti-static component rack, weekly packing, transport vehicle, etc. shall be checked every six months;

2) Operators shall clean anti-static containers and anti-static turnover boxes regularly, and clean anti-static table mats, tools and containers with neutral cleaning agents every month.

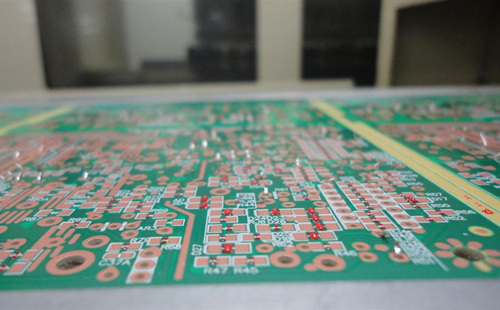

When selecting the appropriate PCB card, it is necessary to select the appropriate one that can ensure the PCB quality, and the tray material must meet the following characteristics:

? High dimensional stability

? Good thermal shock resistance

? It can be kept flat after multiple use

? Corrosion resistance (flux and cleaning agent)

? Non hygroscopic

In the process of PCB manufacturing and assembly in the electronic processing factory, it is not only necessary to use the anti-static card to ensure the production quality, but also to do a good job of anti-static protection in the production workshop. Operators can wear electrostatic bracelets, electrostatic clothing and shoes to protect the PCB production.