PCB manufacturing: correct operation method of aging room

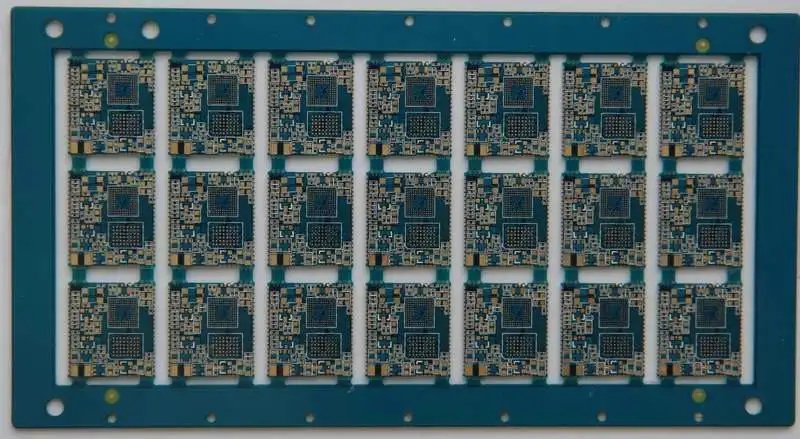

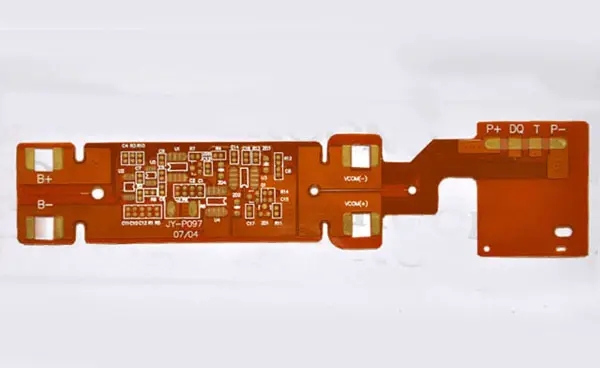

1、 Objective To correctly operate the electrical equipment control of the aging room, verify the product reliability, ensure the product quality, and ensure the safety of property and life. 2、 Scope of Application Applicable to all keyboard/PCB main control board/magnetic head/display and other products of the company III. Before starting the machine, check whether the power supply in the electrical control box is opened and closed, check the reliability of the power supply, turn the voltage change-over switch to AB, BC and AC respectively, check whether the voltage is 380 V, and check whether the oxygen supply fan operates normally. 4、 Startup sequence: set shutdown time and operating temperature. 1. Set the shutdown time: open the chassis to adjust the+- adjustment number on the relay

1、 Purpose

Properly operate electrical equipment control of aging room, verify product reliability, ensure product quality, and ensure property and life safety.

2、 Scope of application

Applicable to all keyboard/PCB main control board/magnetic head/display and other products of the company

3、 Check before startup

Open and close the main power supply in the electrical control box, check the reliability of the power supply, turn the voltage change-over switch to AB, BC and AC respectively, check whether the voltage is 380 V, and check whether the oxygen supply fan operates normally.

4、 Startup sequence: set shutdown time and operating temperature.

1. Set the shutdown time: open the chassis to adjust the+- adjustment number on the relay, and set the time unit beside it (S/H/M)

2. Temperature setting of aging device: adjust the ambient temperature required for the+- regulation experiment on the relay outside the chassis, usually set at 40 ℃

3. When the product is aged, the test values of the three detection thermometers in the aging room must be between 38 ℃ and 42 ℃. The tester should check every 4 hours and make a record on the Temperature Record Form of High Temperature Aging Room. When the temperature is abnormal and cannot be adjusted to 38 ℃ and 8-42 ℃, the test should be stopped. The test can be carried out after the aging device is repaired and OK.

4. Connect devices and products as follows

(1) Turn on the regulated power switch, adjust the voltage to the supply voltage required by the product, measure, verify and confirm with a multimeter.

(2) The maximum number of connected products N < the maximum value of the DC stabilized voltage supply current, which shall not exceed the standard, or the stabilized voltage supply may be burnt out.

(3) Connect the products (only after the completion of 5.1 and 5.2, otherwise the products may be burnt in batches)

(4) During the aging test, it is not allowed to move the aging products and adjust the equipment data at will. If adjustment is required, the power supply must be disconnected.

(5) Follow the product routine test standard.

5、 Post test inspection procedure:

1. After the test, the product must pass the electrical performance test.

2. Execution of all unqualified components (Nonconforming Product Control Procedure)

3. The finished products or defective products after the experiment shall be marked, and the involved product models shall be prepared into a report and entered into the electronic file.

At present, the combustion control of most aging rooms in China is mainly manual control, and the gas flow and air flow are manually adjusted by experience, so it is necessary to master the correct operation method of aging rooms.

The circuit board manufacturer, circuit board designer and PCBA processor will explain the correct operation method of the aging room.