Both sides of PCB double sided boards have wiring. However, if you want to use two wires, you must have a proper circuit connection between them. This "bridge" between circuits is called a pilot hole (via). The pilot hole is a small hole filled with or coated with metal on the PCB, which can be connected with the wires on both sides.

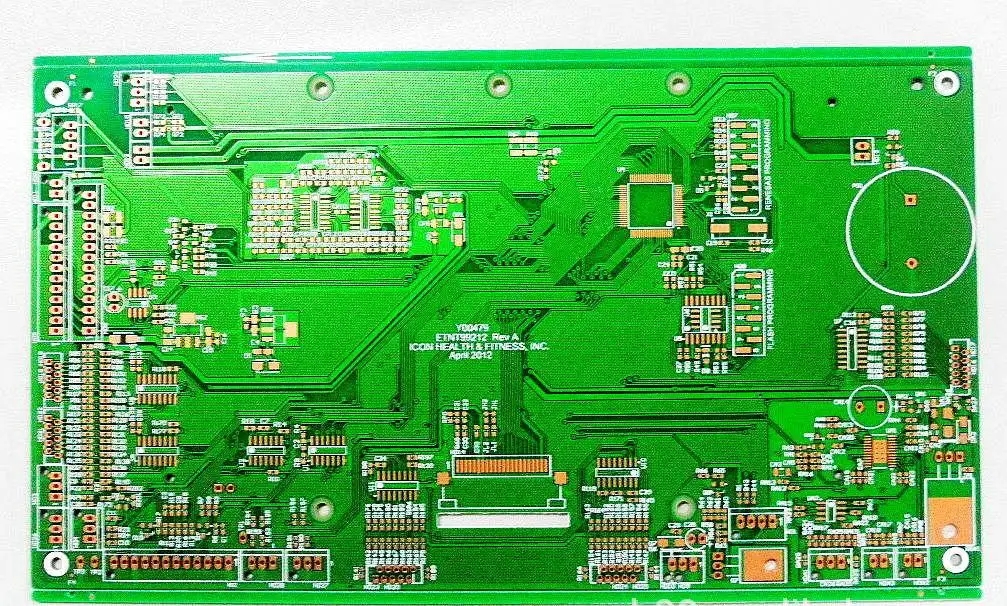

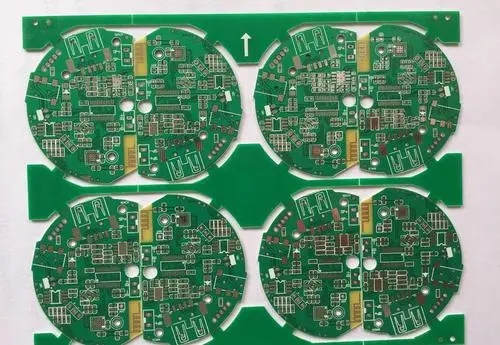

The double panel is a printed circuit board with copper coated on both sides, including the top and bottom. It is the most common and common circuit board. Both sides of its insulating substrate have conductive patterns, and the electrical connections on both sides are mainly connected through holes or pads. Because both sides can be wired, which greatly reduces the difficulty of wiring, it is widely used.

Both sides of the double-sided board have wiring, but to use the wires on both sides, you must have proper circuit connections between them, as shown in the figure. This "bridge" between circuits is called pilot hole. The pilot hole is a small hole filled with or coated with metal on the PCB, which can be connected with the wires on both sides. Because the area of the double-sided board is twice as large as that of the single panel, the double-sided board solves the problem of staggered wiring in the single panel (it can be connected to the other side through holes), and is more suitable for circuits more complex than the single panel.

Generally, the fabrication method of PCB double-sided boards is to first make the inner layer graphics, then make single or double-sided substrates by printing and etching, and incorporate them into the designated interlayer, and then heat, pressurize and glue them. As for the later drilling, it is the same as the plating through hole method of double-sided boards. These basic manufacturing methods have not changed much from the construction methods dating back to the 1960s. However, with the maturity of materials and processing technologies (such as pressing and bonding technology, solution to the problem of glue residue generated during drilling, and improvement of film), the characteristics attached to the multilayer board are more diversified.

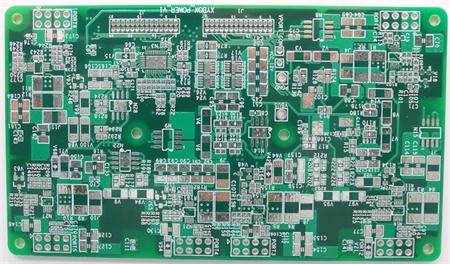

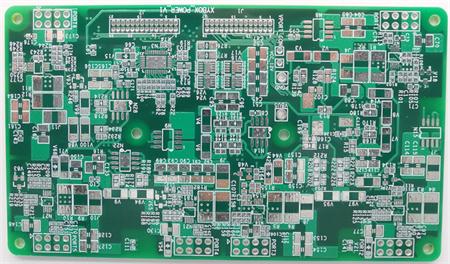

The production of double-sided boards is more complicated than that of single panel, mainly due to the following two reasons:

(1) The top and bottom layers of copper clad plate shall be wired.

(2) Wires on the top and bottom layers shall be connected with metallized vias.