In order to test whether the components on the circuit board meet the specifications and solderability, we need test points on the circuit board. If we want to check whether the resistance on a circuit board is abnormal, the most basic method is to use a multimeter to measure its two ends. How can we know that the circuit board is a test point?

During troubleshooting, it is necessary to measure the power supply voltage. At this time, it is necessary to find the power supply voltage line on the circuit board.

To find the voltage test point, it is necessary to find the largest electrolytic capacitor with the highest withstand voltage and capacity on the circuit board. This capacitor is the filter capacitor of the whole machine. The positive DC voltage supply circuit is the DC working voltage test terminal of the whole machine.

If troubleshooting is required, the following test points should also be found:

Power supply pin of integrated circuit

Triode collector

Emitter or collector of electronic filter tube

Voltage to ground at a point in the circuit

Calculate the test points of PCB:

A NET is the routing of a PCB, and the end points must be stitched.

Calculate the test points of PCBA circuit board:

The number of points is one NET pin, and the total number of NET pins is as many as there are.

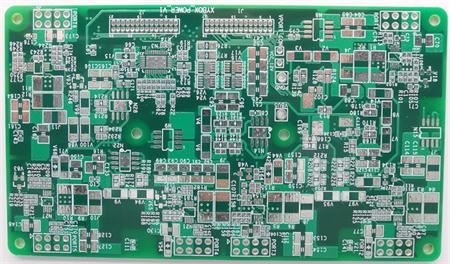

Manual circuit board test fixture refers to: apply control signal and input signal to the circuit board under test through needle bed, manual test fixture, printed board pin, input/output interface, read the output signal of the circuit board under test in real time, and judge whether the performance (or function) of the circuit board under test is correct through a series of data analysis and processing.

Due to different test requirements and test objects of users, their specific performance (or function) test principles and methods are also different. It needs to be tailored to meet user requirements.

For example, a Japanese funded professional video recorder enterprise -- the functional test tooling for video recorder mainboard

1、 Requirements

1. Check whether the functions of the main board of the video recorder are correct (video recording, video playback, rewinding, pause, input production number to the video recorder, input clock, etc.)

2. Test equipment: computer (RS232 interface), audio generator, power supply system, video recorder, audio receiver, TV, oscilloscope, etc.

2、 Test block diagram (check the main board of the video recorder)

3、 Working principle

The computer is connected to the main board of the video recorder through the interface, so the time, factory number and system of the main PCB board can be set read-write. The audio signal is sent to the tooling CN1, and the power supply system is turned on. At the same time, connect the audio related signal CN5 of the tooling to the audio receiver; Connect the relevant waveform test point CN6 on the tooling to the oscilloscope; At the same time, monitor the correctness of the video playback function of the video recorder on the television.