What is the significance of PCB impedance to PCB, and why should PCB be impedance? This paper first introduces what impedance is and the types of impedance, then introduces why PCB should be impedance, and finally expounds the significance of impedance to PCB, and specifically follow the small editor to understand.

1、 What is impedance

In a circuit with resistance, inductance and capacitance, the resistance to alternating current is called impedance. Impedance is usually represented by Z, which is a complex number. The real part is called resistance, and the imaginary part is called reactance. The blocking effect of capacitance on alternating current in the circuit is called capacitive reactance, the blocking effect of inductance on alternating current in the circuit is called inductive reactance, and the blocking effect of PCB capacitance and inductance on alternating current in the circuit is called reactance. The unit of impedance is ohms.

2、 Resistance welding type

(1) Characteristic impedance In computer, wireless communication and other electronic information products, the energy transmitted in the PCB circuit is a square wave signal (called pulse) composed of PCB voltage and time, and the resistance it encounters is called characteristic impedance.

(2) The differential impedance drive end inputs two identical signal waveforms with opposite polarity, which are respectively transmitted by two differential lines, and the two differential signals are subtracted at the receiving end. The differential impedance is the impedance Zdiff between two lines.

(3) Odd mode impedance The impedance Zoo of one line to ground in two lines is the same.

(4) The impedance Zcom when two lines are connected by two identical signal waveforms with the same input polarity at the even mode impedance drive end.

(5) Common mode impedance The impedance Zoe of the one line to the ground in the two lines is the same, usually greater than the odd mode impedance.

3、 Why be impedance

The impedance PCB shouldof pcb circuit board refers to the parameters of resistance and reactance, which hinder the alternating current. In pcb production, impedance processing is essential. The reasons are as follows:

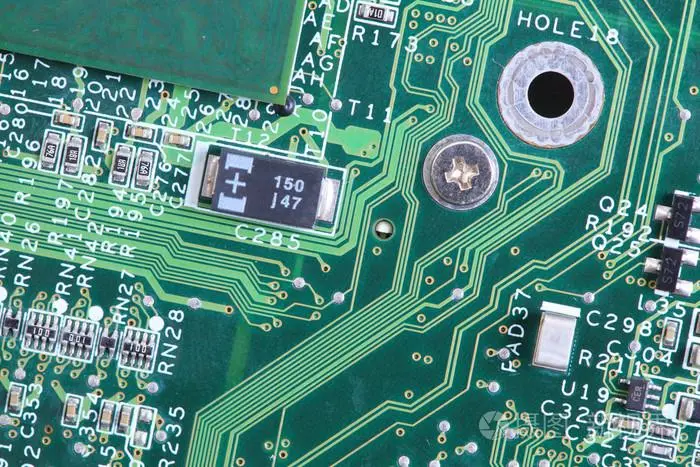

1. PCB circuit (bottom of the board) should consider the connection and installation of PCB electronic components. After the connection, the conductivity and signal transmission performance should be considered. Therefore, the lower the impedance, the better, and the resistivity should be less than 1&TIMes per square centimeter; 10-6 or less.

2. During PCB production, PCB must go through the process of copper deposition, electrotinning (or chemical plating, or thermal spraying), connector soldering and other production links, and the materials used in these links must ensure the low resistivity to ensure that the overall impedance of the PCB meets the product quality requirements and can operate normally.

3. The tin plating of PCB is the most likely problem in the whole PCB production, and is the key link affecting the impedance. The biggest defects of electroless tin coating are easy to change color (easy to oxidize or deliquescence) and poor solderability, which will lead to difficult soldering of PCB, high impedance and poor conductivity or unstable performance of the whole board.

4. There will be various signals transmitted in the conductor of PCB. When the frequency must be increased to improve the transmission rate, if the circuit itself is different due to etching, stack thickness, wire width and other factors, the impedance value will change, the signal will be distorted, and the usability of PCB will decline. Therefore, it is necessary to control the impedance value within a certain range.

4、 Meaning of impedance to PCB

For the electronic industry, according to the industry survey, the most fatal weakness of the electroless tin coating is that it is easy to change color (i.e. easy to oxidize or deliquescence), poor solderability leads to difficult welding, high impedance leads to poor conductivity or unstable performance of the whole board, and easy to grow tin must lead to PCB circuit short circuit, even burning or fire events.